Control box for single-phase basket motor

A control box and hanging basket technology, which is applied to the starter of a single-phase induction motor, motor generator/starter, etc., can solve the problems of affecting the starting torque, difficult to achieve the effect of use, and large starting torque. Achieve the effect of realizing asynchronous operation, reducing bumping phenomenon and increasing rain protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

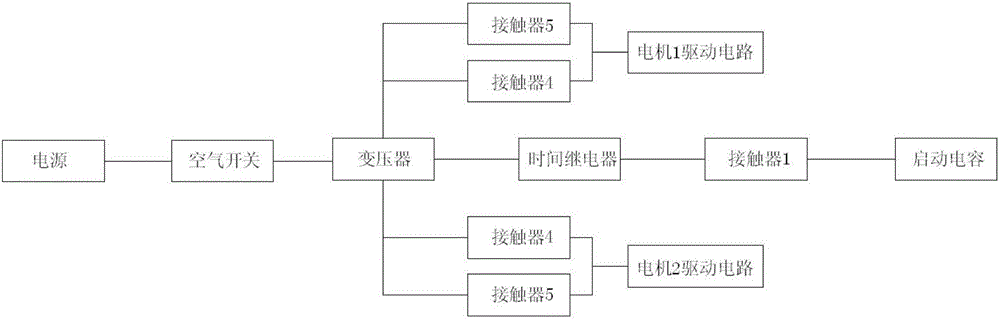

[0013] A single-phase hanging basket motor, including a single-phase motor body and its internal control circuit. After changing the original three-phase asynchronous motor into a single-phase motor, since the three-phase asynchronous motor is controlled by a disconnect switch, the single-phase motor Centrifugal switch contacts are easy to stick when starting at low voltage, and motor windings and capacitors are easy to burn out, so it is replaced with multiple contactors and time relays to control the on-off of the starting capacitor.

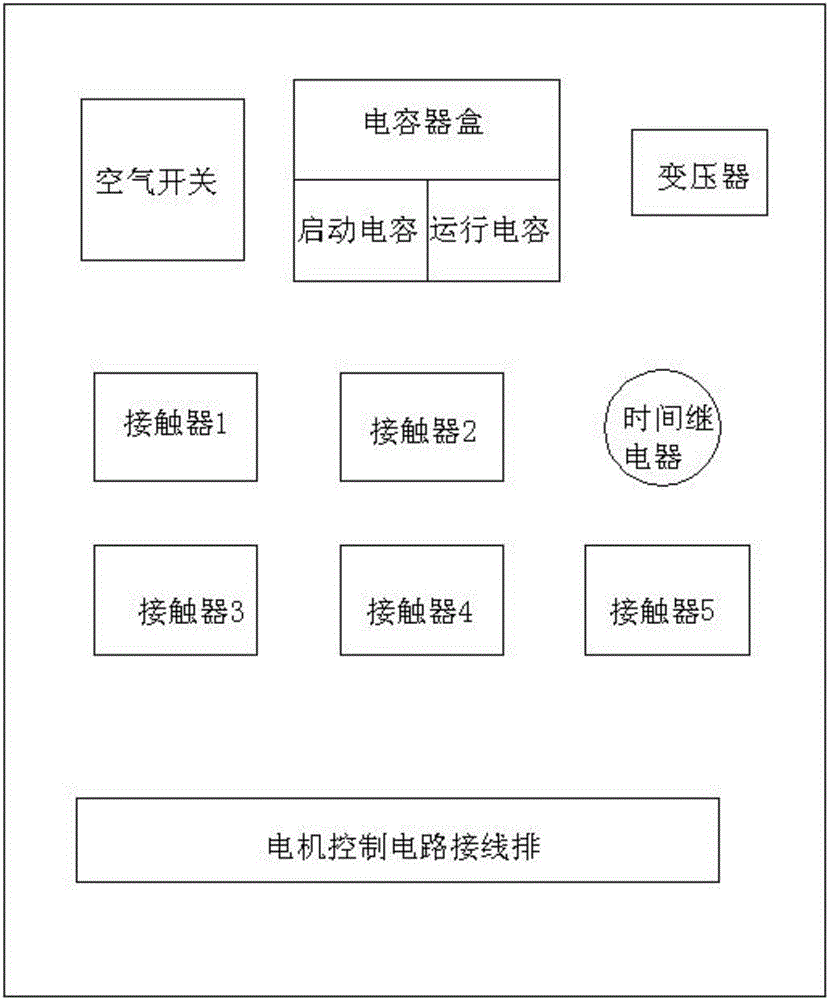

[0014] Its control circuit includes a transformer, a time relay, five contactors, a starting capacitor and an air switch. The power supply is divided into three circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com