Method for inhibiting opening sizes of U-shaped armatures

An armature and U-shaped technology, which is applied in the field of suppressing the opening size of the U-shaped armature, and can solve problems such as changes in the opening size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

[0015] The invention discloses a method for suppressing the opening size of a U-shaped armature, such as figure 1 As shown, the following steps may be included:

[0016] Step S101, designing a tool for limiting the U-shaped armature;

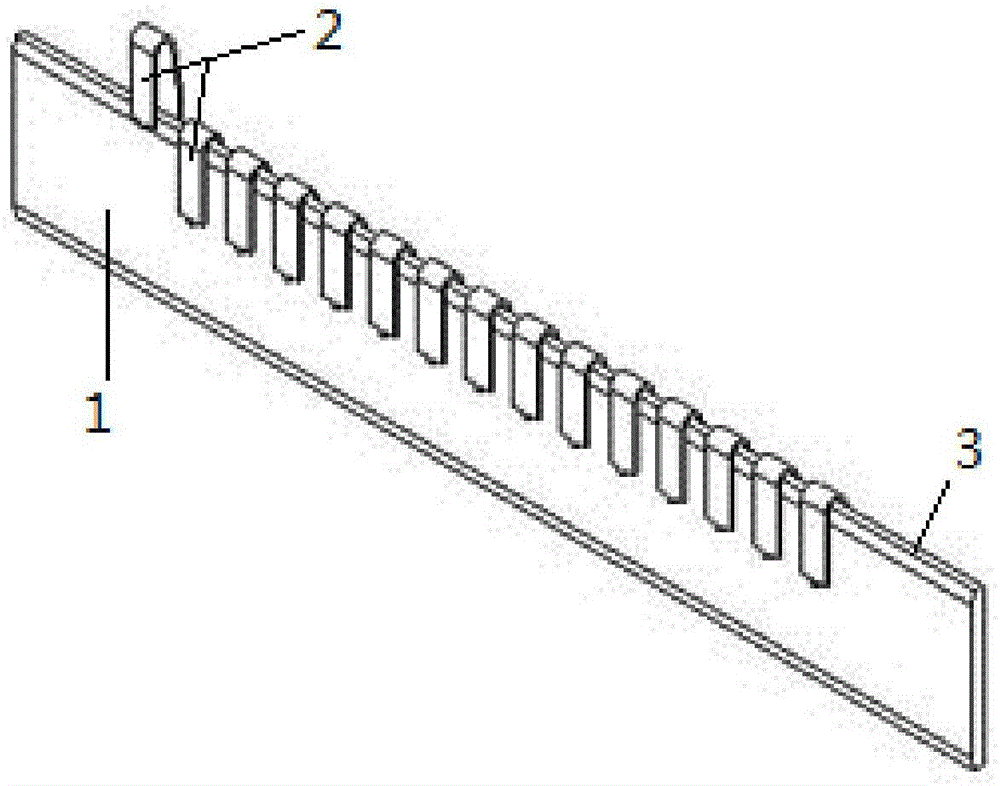

[0017] In this example, if figure 2 As shown, the tool 1 for restraining the U-shaped armature can be made of high-temperature-resistant alumina ceramics, and can be made into a cuboid. Its processing thickness corresponds to the opening size of the U-shaped armature 2, and its tolerance is generally controlled at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com