Hot air tea fixation machine

A greening machine and tea technology, which is applied in tea processing before extraction, etc., can solve problems such as burnt edges of tea leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

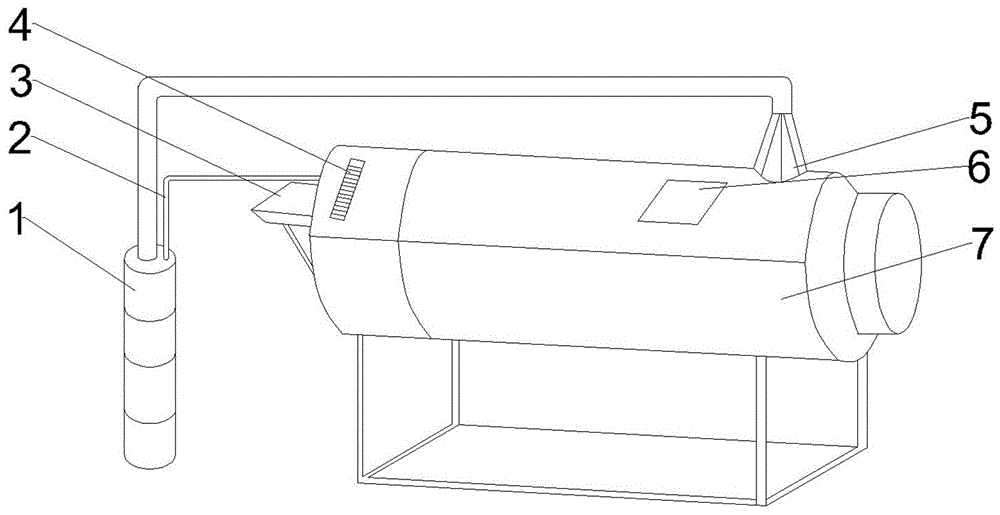

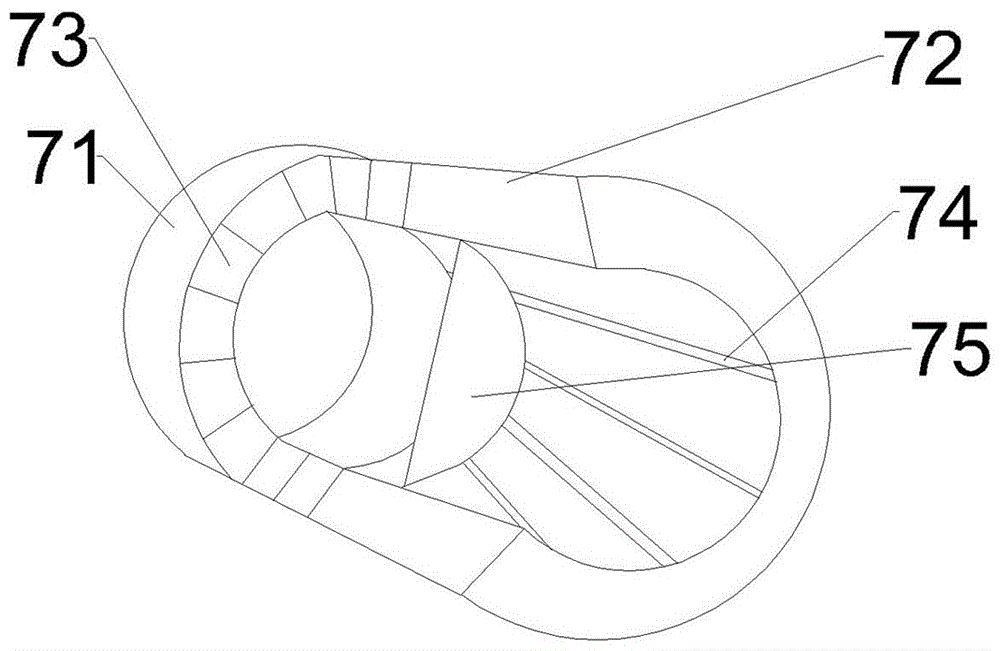

[0021] The reference signs in the drawings of the description include: hot blast stove 1, gas pipe 2, input port 3, thermometer 4, air pump 5, observation port 6, drum 7, front drum 71, rear drum 72, high temperature resistant heat insulation pad 73, guide Blade 74, blocking plate 75.

[0022] The embodiment is basically as attached figure 1 As shown: the drum 7 is fixedly connected to the bracket, the inner wall of the drum 7 is provided with a guide vane 74, the drum 7 is provided with a tea input port 3 and a tea output port, the edge of the tea input port 3 is connected to one end of the trachea 2, and the other end of the trachea 2 is connected to To the hot blast stove 1 that supplies air to the drum 7, the outer wall of the drum 7 is provided with a thermometer 4, and the drum 7 is also connected with an air pump 5, and the air pump 5 is connected with a pipeline,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com