Quick cleaning device for cement barrel for building

A cleaning device and a technology for construction, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of time-consuming and laborious, low cleaning efficiency, high labor intensity, etc. Reliable, long-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

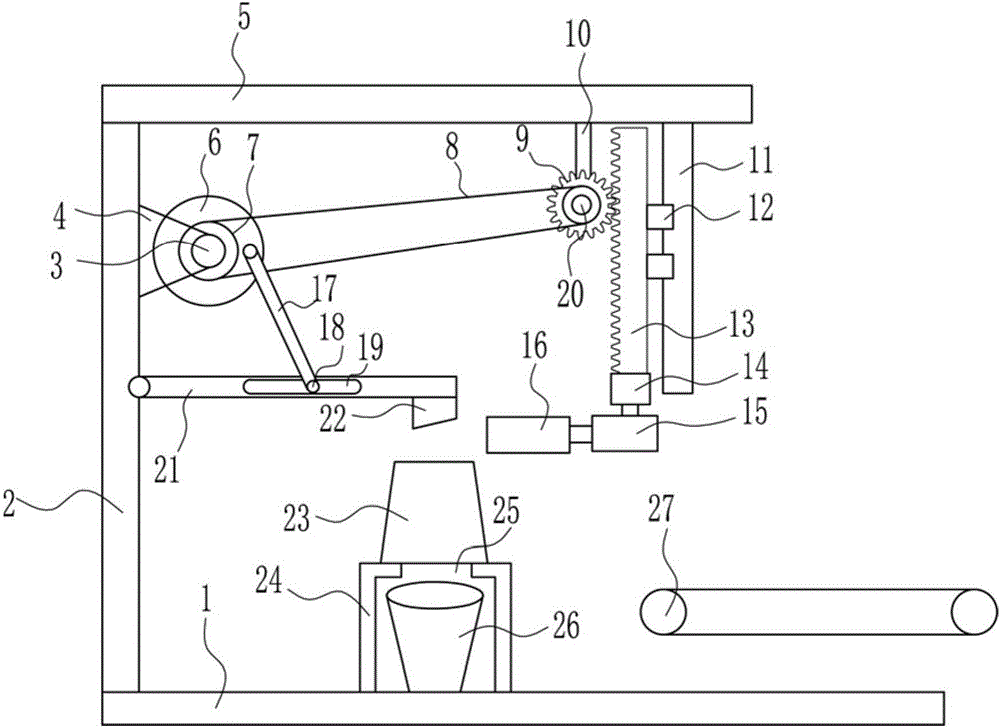

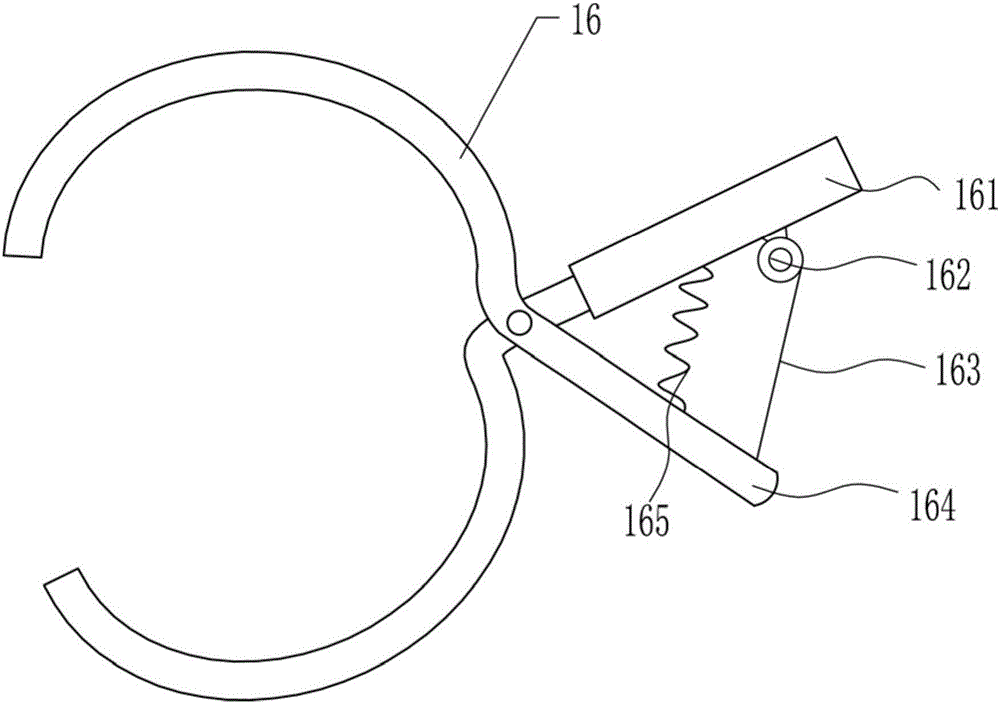

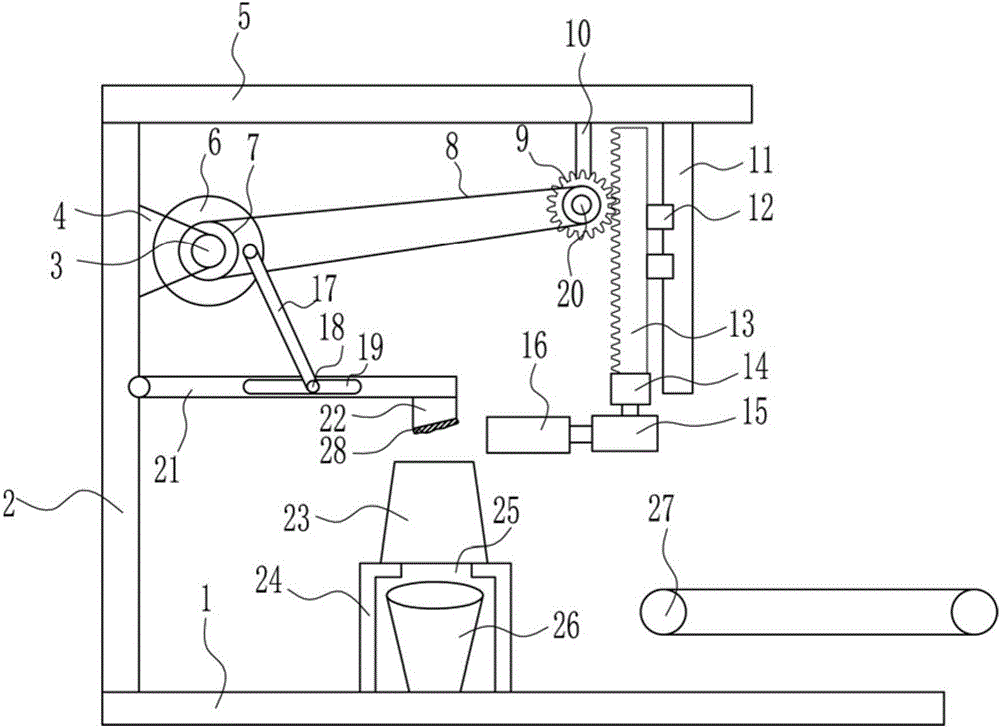

[0035] A kind of fast cleaning device for cement barrels used in construction, such as Figure 1-6As shown, it includes a bottom plate 1, a left bracket 2, a first motor 3, a mounting seat 4, a top plate 5, a disk 6, a driving wheel 7, a belt 8, a gear 9, a pole 10, a slide rail 11, a slider 12, Rack 13, second motor 14, electric push rod 15, clamping device 16, connecting rod 17, rolling shaft 18, driven wheel 20, swing rod 21, knocking block 22, placing plate 24, collection frame 26 and conveying device 27 , the upper left side of the base plate 1 is provided with a left bracket 2, the upper middle part of the base plate 1 is provided with a placement plate 24, and the top of the placement plate 24 has a circular through hole 25, and the base plate 1 in the placement plate 24 is provided with a collecting frame 26, and the base plate 1 The upper right side is provided with conveying device 27, and the top of left support 2 is provided with top plate 5, and the right side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com