Organic liquid fertilizer fermentation system and application thereof

A fermentation system and organic liquid fertilizer technology, applied in the field of organic liquid fertilizer fermentation system, can solve the problems of organic liquid fertilizer re-filtering and storage not well solved, difficult to meet the fermentation of a large amount of materials, frequent microbial activities, etc., to achieve reduction The effect of manual participation intensity, reduced workload, and convenient waste removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

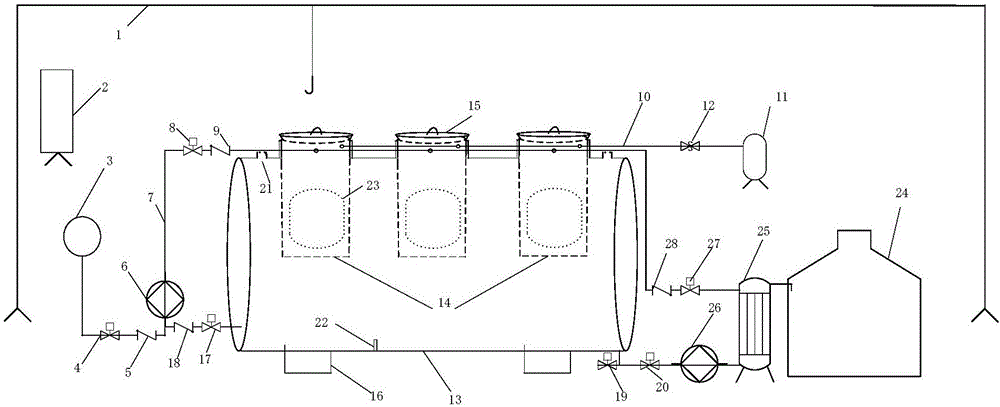

[0051] A kind of organic liquid fertilizer fermentation system, specific structure is as follows figure 1 As shown, it includes a water injection device, an aeration device, a liner type fermentation device, a gantry 1, a fermentation liquid storage device and a control device 2.

[0052] Wherein, the liner type fermentation device includes a fermenter 13 , an inner liner 14 and a tank cover 15 .

[0053] The inner tank 14 is located inside the fermenter 13, and filter holes are evenly distributed on the tank wall, the inner tank 14 is detachably connected to the fermenter 13, and the inner tank 14 is also provided with a mesh cage 23. The mesh cage 23 is used to hold fermented materials.

[0054] In this embodiment, there are three inner tanks 14, and each inner tank 14 corresponds to a tank mouth located on the top of the fermenter 13, and the tank mouth is used for the inner tank 14 to enter and exit. The size of the mouth of the tank is equivalent to the size of the mate...

Embodiment 2

[0067] A kind of fermentation method of organic liquid fertilizer, adopts the system realization of embodiment 1, concrete work process is:

[0068] (1) Open the tank cover, use the gantry system to pull out the liner, take out the cage, put the organic material and microbial agent in proportion and put them into the cage, put the cage into the liner, and finally use the gantry Put the liner into the fermenter and seal the lid;

[0069] (2) Turn on the water pump, the water injection valve and the liquid inlet valve (at this time, the liquid outlet valve and the fourth valve are closed), and inject clean water into the fermentation tank body. The amount of clear water injected into the fermentation tank is controlled according to the feedback information of the liquid level sensor.

[0070] (3) Carry out aerobic fermentation after water injection, and use the control system to control the working time of the air pump and air valve every day, as well as the opening and closing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com