Self-induction Magneto-rheological Damping Pipe Clamp

A vibration damping tube and magneto-rheological technology, applied in the direction of shock absorbers, shock absorbers, pipe supports, etc., can solve problems such as inconvenient installation and fixing of pipelines, failure to ensure system stability, and pipelines affecting system safety, etc., to achieve Improve pipeline life and reliability, simple and convenient operation, and reduce pipeline vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

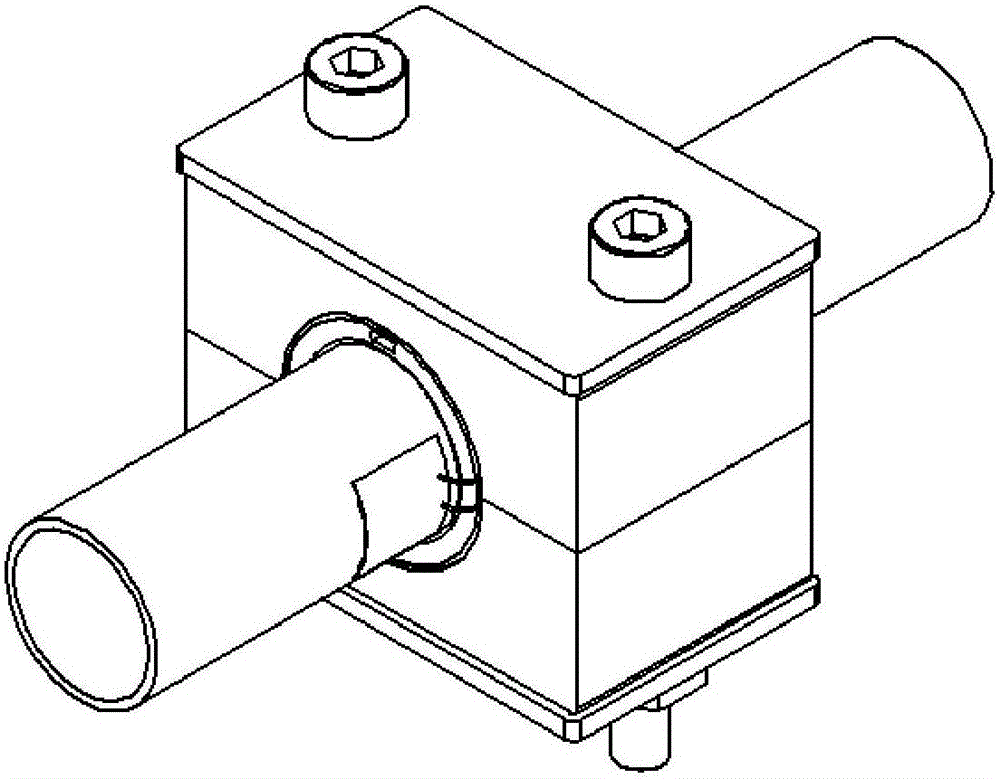

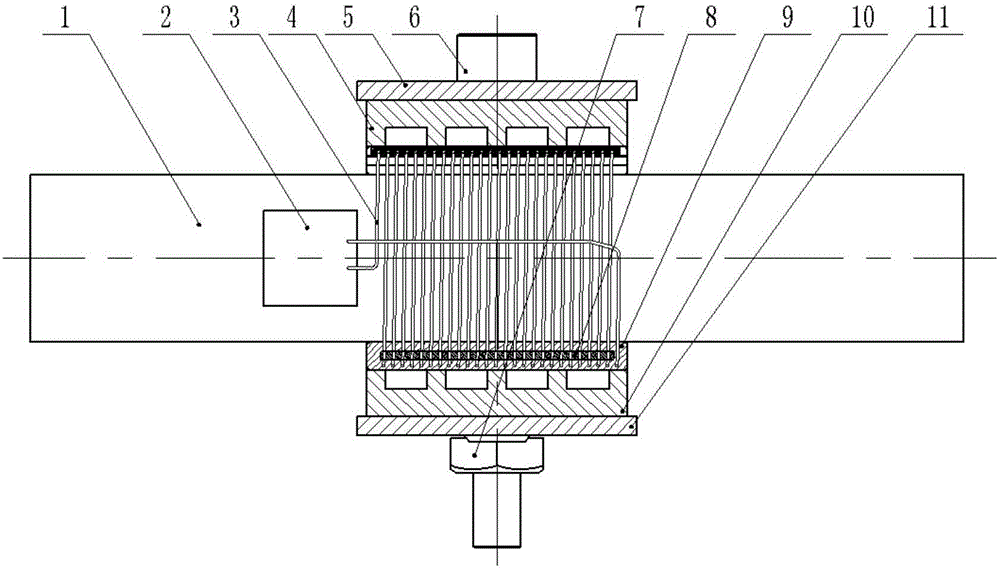

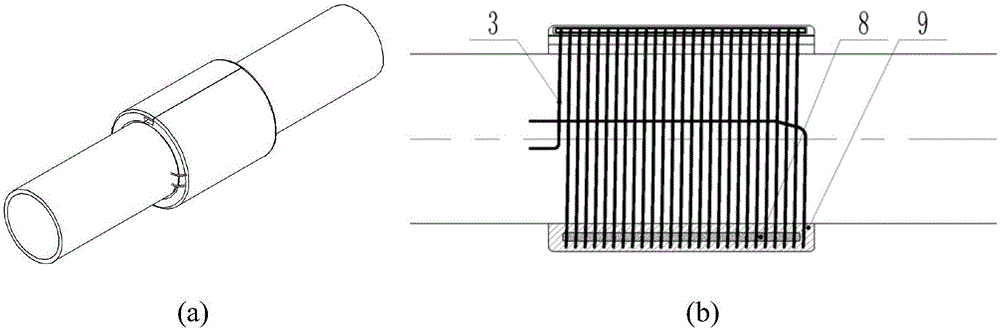

[0024] Such as Figure 1~2 As shown, a self-induction magneto-rheological damping pipe clip of the embodiment of the present invention has a damping rubber sleeve 9 on the outside of the pipeline 1, and a magneto-rheological fluid material 8 and a metal coil are inside the vibration-damping rubber sleeve. 3. Both ends of the metal coil wire are connected to a MEMS vibrating micro-energy device 2 attached to the outer wall of the pipeline. The upper and lower pipe clamps 4 and 10 are fastened to the vibration-damping rubber sleeve, and the upper and lower pipe clamps pass through The fixed top cover 5 and the fixed bottom plate 11 are fixed by two pairs of hexagon socket bolts 6 and nuts 7 . There are anti-slip depressions in the upper and lower pipe clamps (see figure 2 ), this design can not only ensure the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com