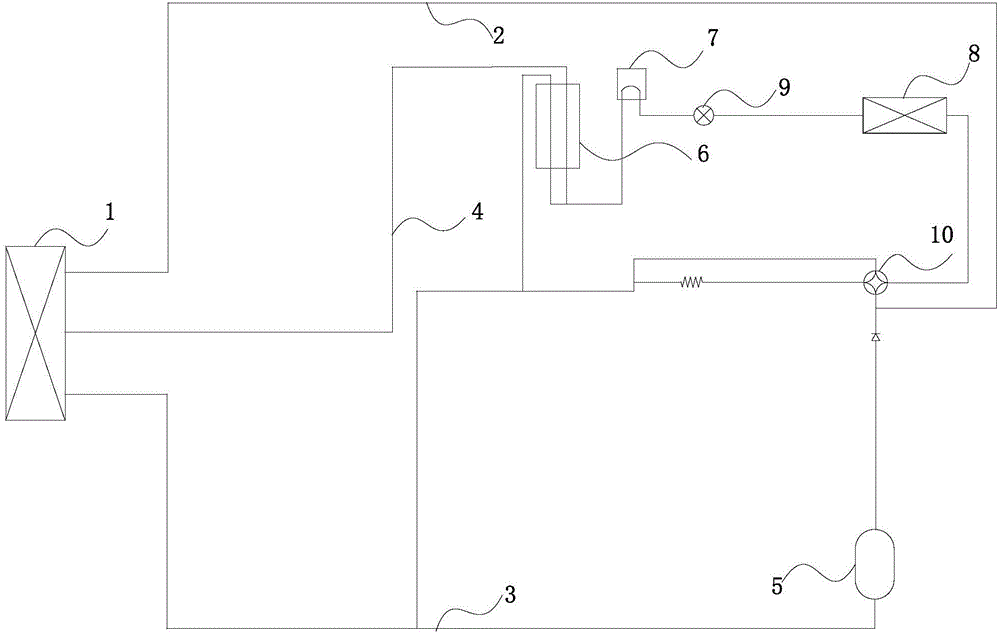

Air conditioner heat recycling system

A heat recovery and air-conditioning technology, applied in air-conditioning systems, space heating and ventilation, space heating and ventilation details, etc., can solve the problems that the refrigerant cannot flow through, and the heat dissipation of the drive cooling module 7 cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

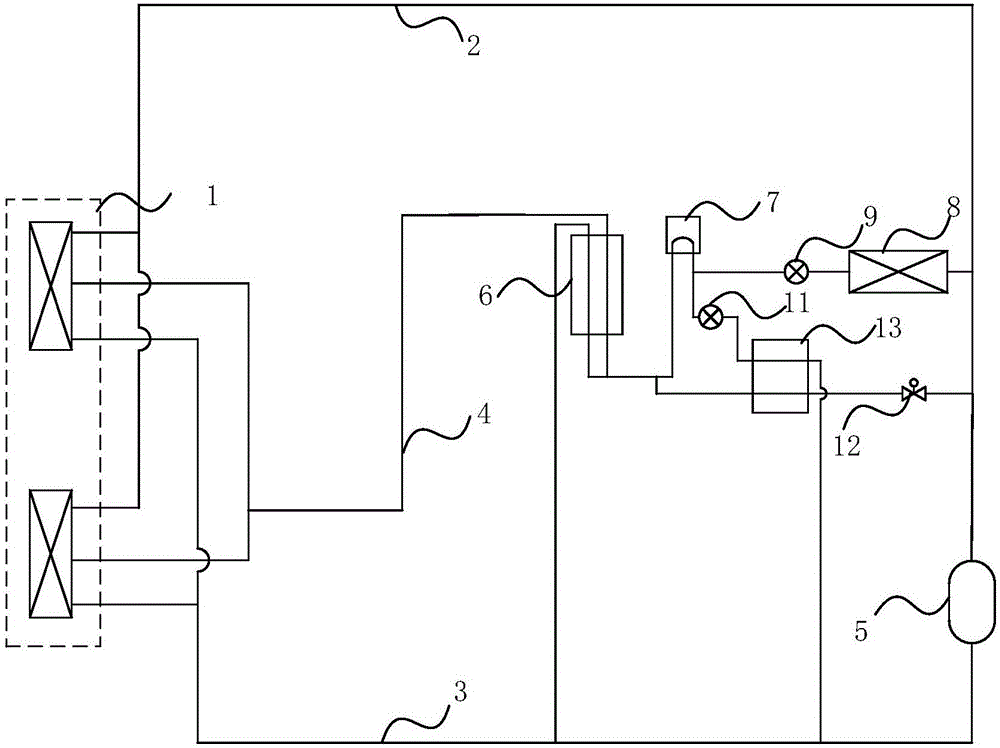

[0022] figure 2 It is a schematic structural diagram of an air-conditioning heat recovery system provided in Embodiment 1 of the present invention. The system includes an internal unit 1, a high-pressure air pipe 2, a low-pressure air pipe 3, a liquid pipe 4, a compressor 5, a subcooler 6, and a drive heat dissipation module 7 , Outdoor unit heat exchanger 8, first electric control valve 11, second electric control valve 12 and heat exchanger 13.

[0023] Among them, the first electronically controlled valve 11 is connected in series between the liquid outlet pipe of the driving heat dissipation module 7 and the low-pressure air pipe 3 to form a first pipeline; the second electronically controlled valve 12 is connected in series between the liquid inlet pipe and the high-pressure air pipe of the driving heat dissipation module 7 2, forming a second pipeline; the heat exchanger 13 respectively connects the first pipeline and the second pipeline, and transfers the heat of the h...

Embodiment 2

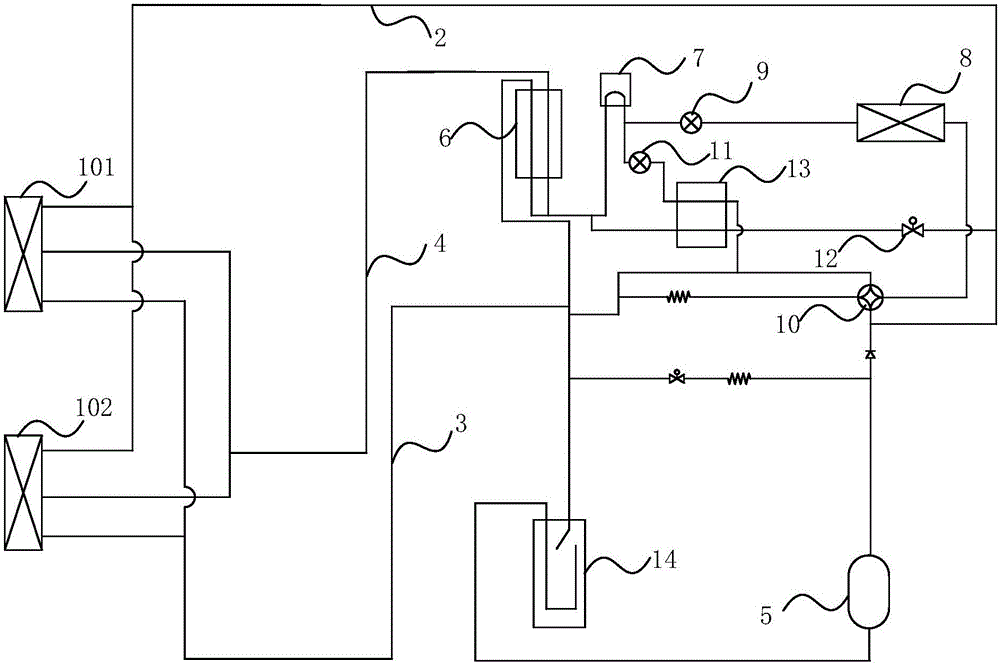

[0035] image 3 It is a schematic structural diagram of an air-conditioning heat recovery system provided in Embodiment 2 of the present invention. The system includes an indoor unit, a high-pressure air pipe 2, a low-pressure air pipe 3, a liquid pipe 4, a compressor 5, a subcooler 6, a drive cooling module 7, an outdoor unit heat exchanger 8, a heating electronic expansion valve 9, and a four-way valve 10 , the first electric control valve 11, the second electric control valve 12, the heat exchanger 13 and the gas-liquid separator 14. Wherein, the internal machine is connected with the high-pressure air pipe 2, the low-pressure air pipe 3 and the liquid pipe 4. The low-pressure air pipe 3 is connected to the air inlet of the compressor 5 , the high-pressure air pipe 2 is connected to the air outlet of the compressor 5 , and a gas-liquid separator 14 is connected in series between the internal machine and the compressor 5 . The compressor 5 compresses the refrigerant flowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com