Aviation engine's multi-joint blade throat diameter gauge

An aero-engine and throat diameter technology, applied in the direction of mechanical devices, mechanical measuring devices, measuring devices, etc., can solve the problems of easy scratches on the surface of the blades, and achieve the effect of ensuring the appearance quality and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

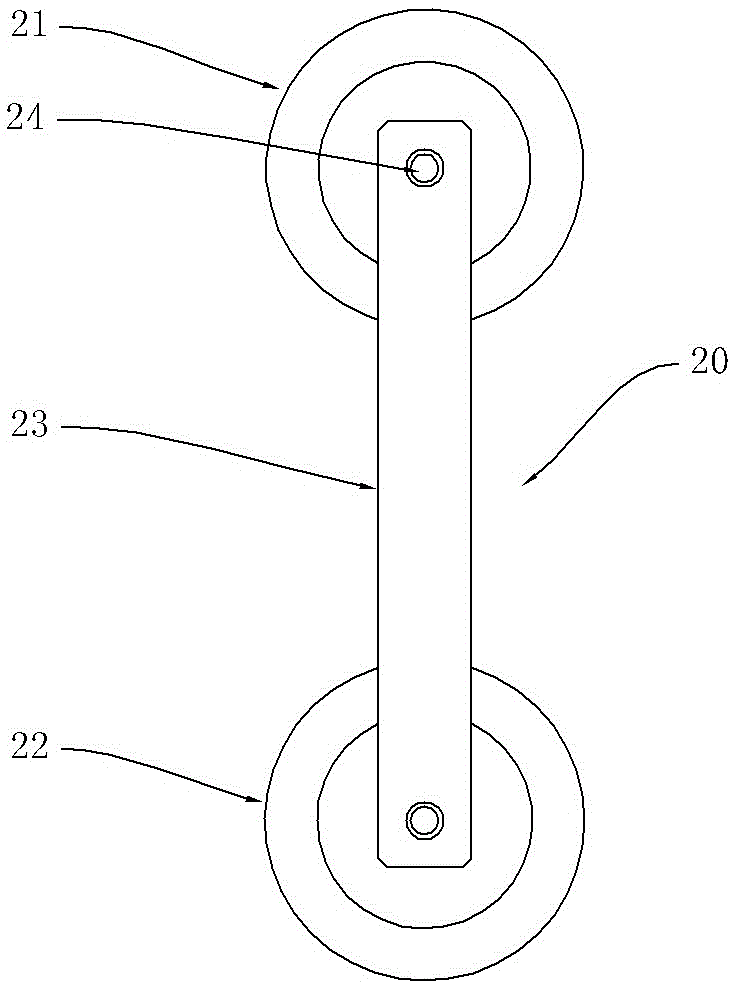

[0017] Such as Figure 3~Figure 5 As shown, it includes a connecting rod 23, a through-end measuring block 21 and a stop-end measuring block 22; the two ends of the connecting rod 23 are symmetrically provided with slots; the through-end measuring block 21 and the stop-end measuring block 22 are annular and pass through The connector is rotatably supported in the slots 231, 232 at both ends of the connecting rod 23, the outer diameter of the through-end measuring block is equal to the lower limit of the throat diameter of the position to be measured, and the outer diameter of the end-stop measuring block is equal to the lower limit of the throat diameter of the position to be measured. The upper limit of the throat diameter of the point is equal. Specifically, the connecting piece is a pin, and the rod body of the pin is provided with an optical axis part and threaded parts on both sides of the optical axis part. The perforation in the annular center of the block 22 is in slid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com