Tail-end card receiving and collecting apparatus of intelligent production line

A smart card and production line technology, which is applied in the direction of instruments, computer components, transmission record carriers, etc., can solve the problems of complex structure of smart card production equipment, difficulty in completely transporting smart cards, and reduced equipment volume, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

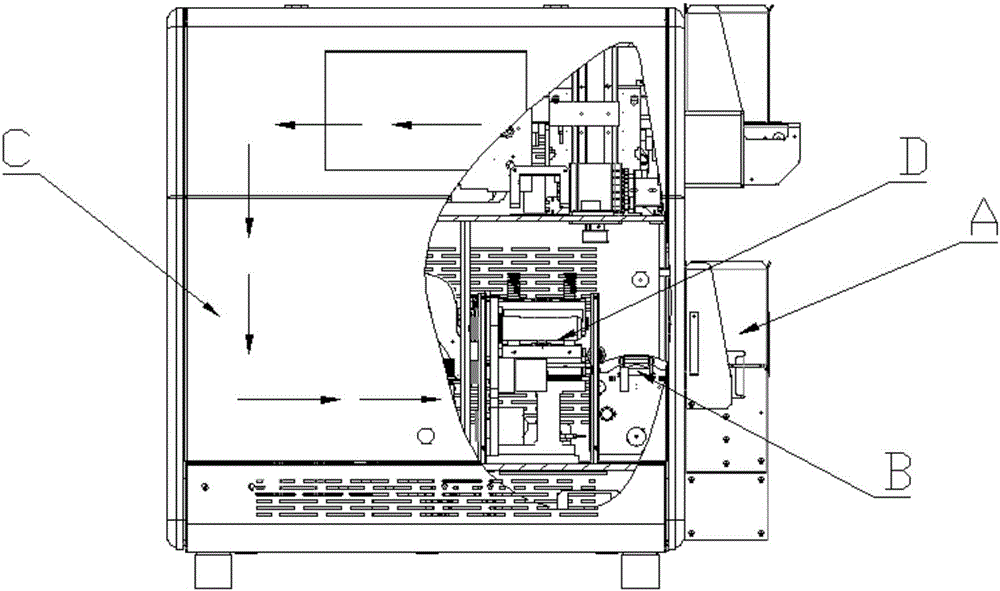

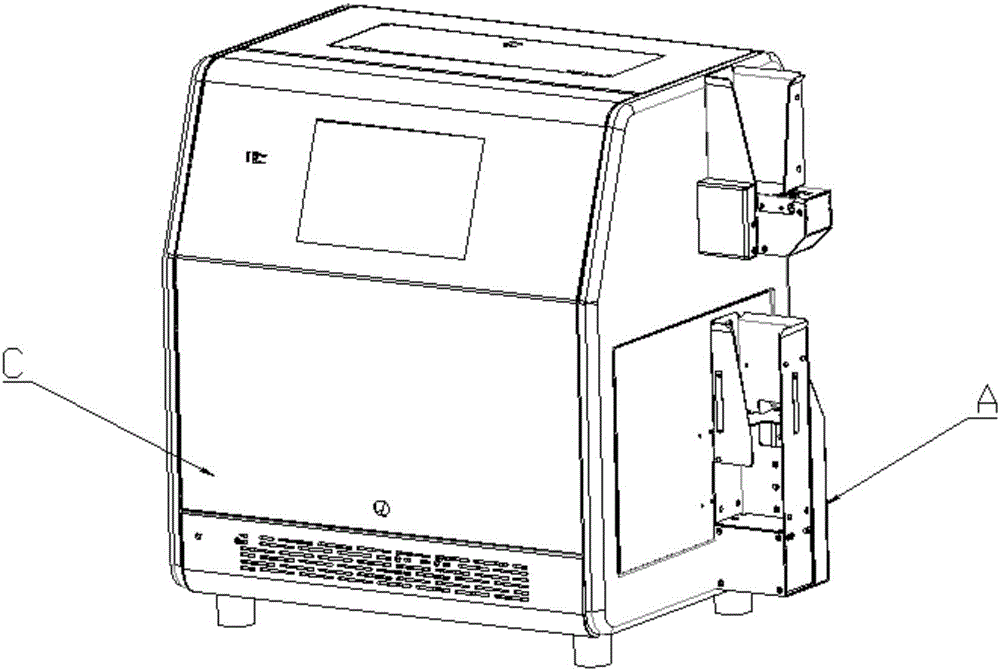

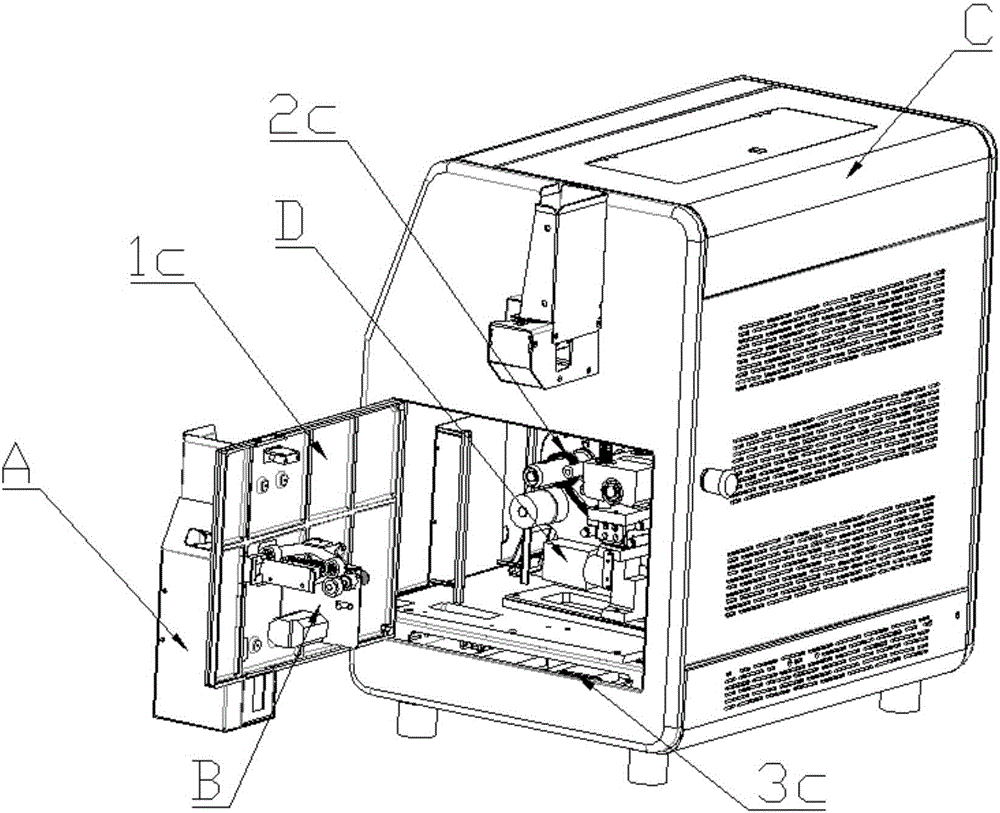

[0037] see Figure 1 to Figure 10 The terminal card receiving and card receiving device of the smart card production line in this embodiment includes a chassis C, a card collecting device A and a card transition conveying mechanism B, wherein the chassis C is provided with an opening on the side corresponding to the end of the card conveying channel, A cabinet side door 1c that can be opened outwards is installed at the opening, and a bayonet outlet is provided on the cabinet side door 1c. The above-mentioned card collection device A is connected, and the inner side is connected with the card transition conveying mechanism B. A hot stamping module D is arranged in the cabinet, and the hot stamping module D is installed at the end of the card conveying channel of the sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com