A motor relay capable of fast closing of contacts

A fast closing and relay technology, applied in the contact drive mechanism, the power device inside the switch, etc., can solve problems such as endangering the safety of motor relays, reducing the electrical life and reliability of high-power relay contacts, and explosions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

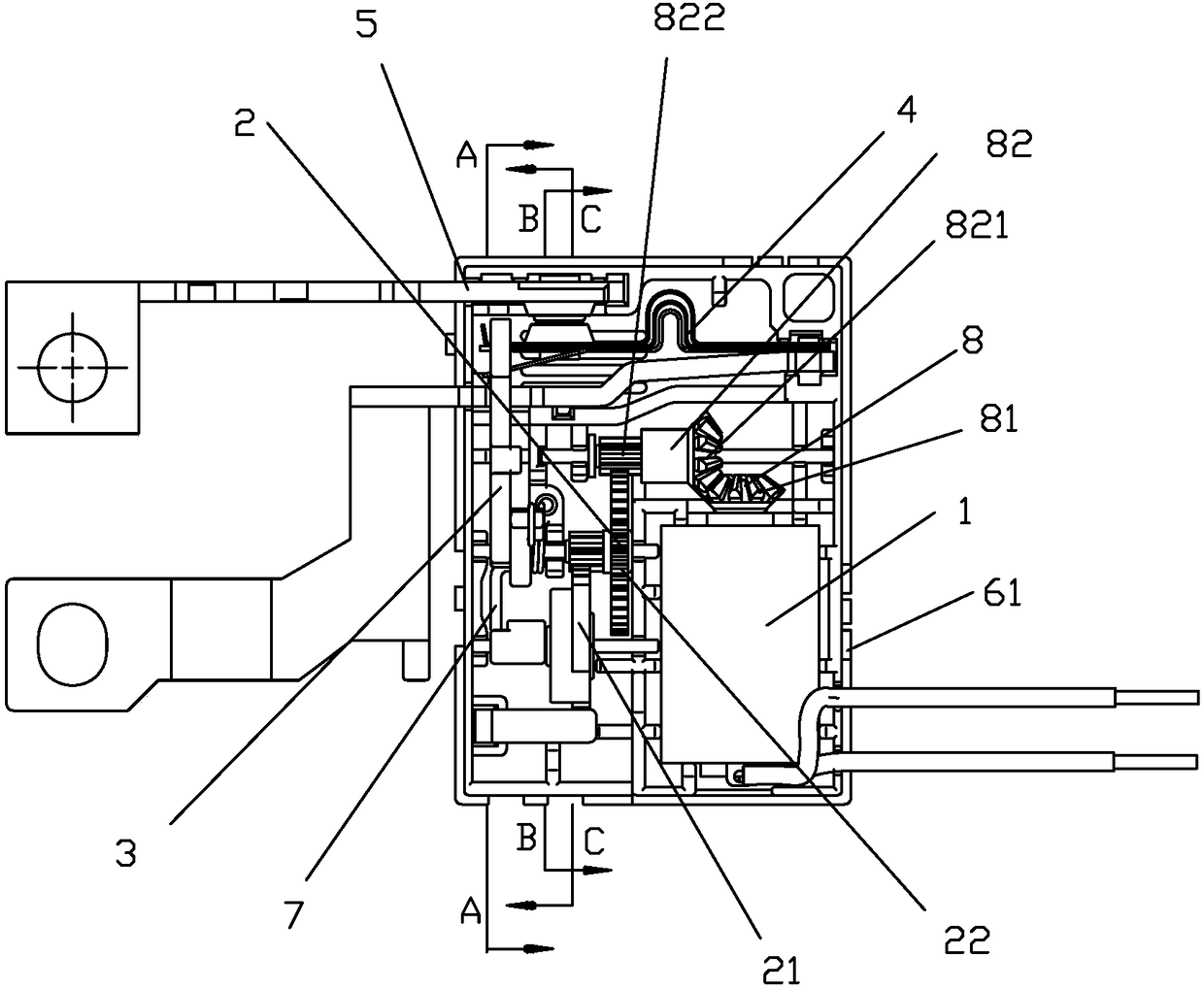

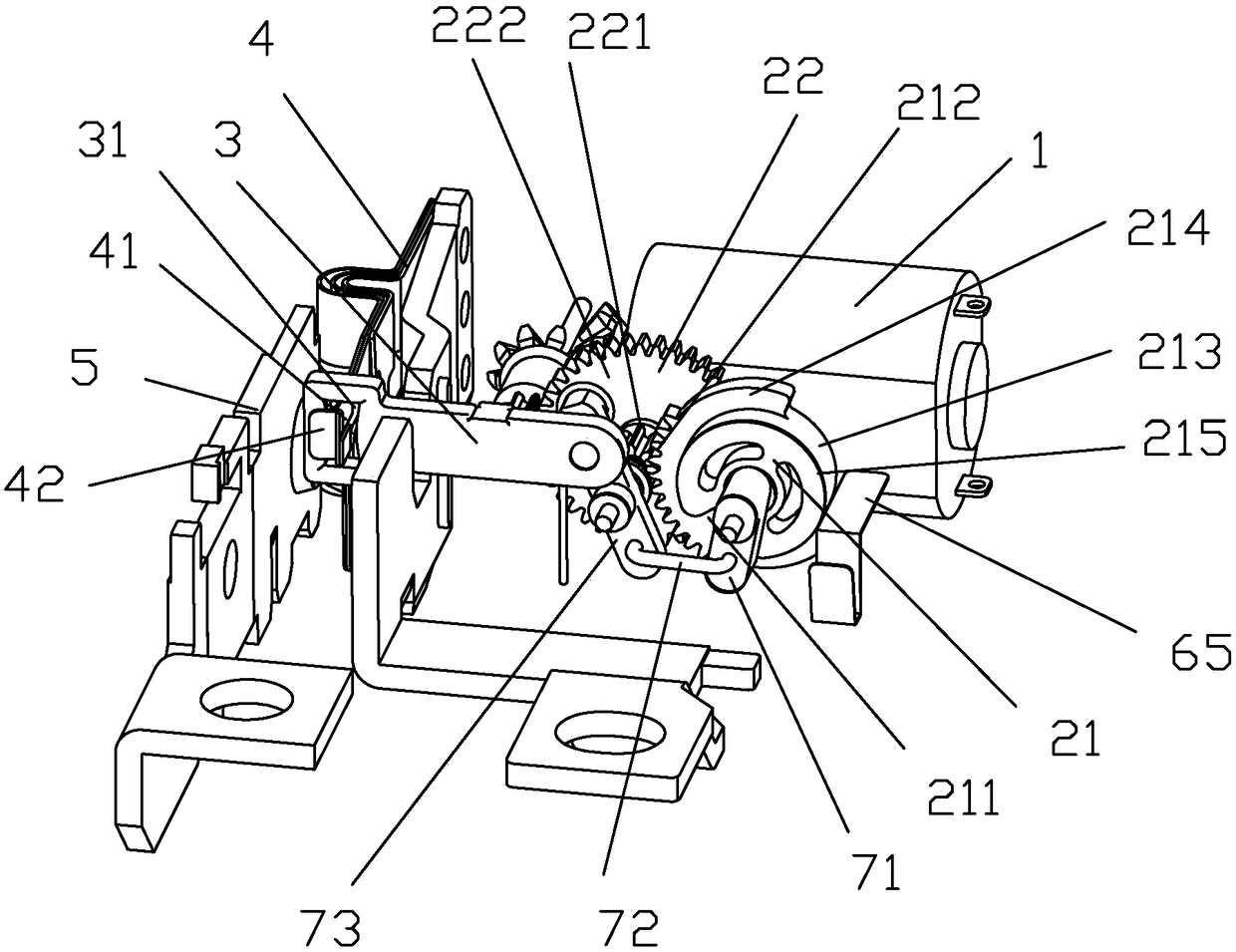

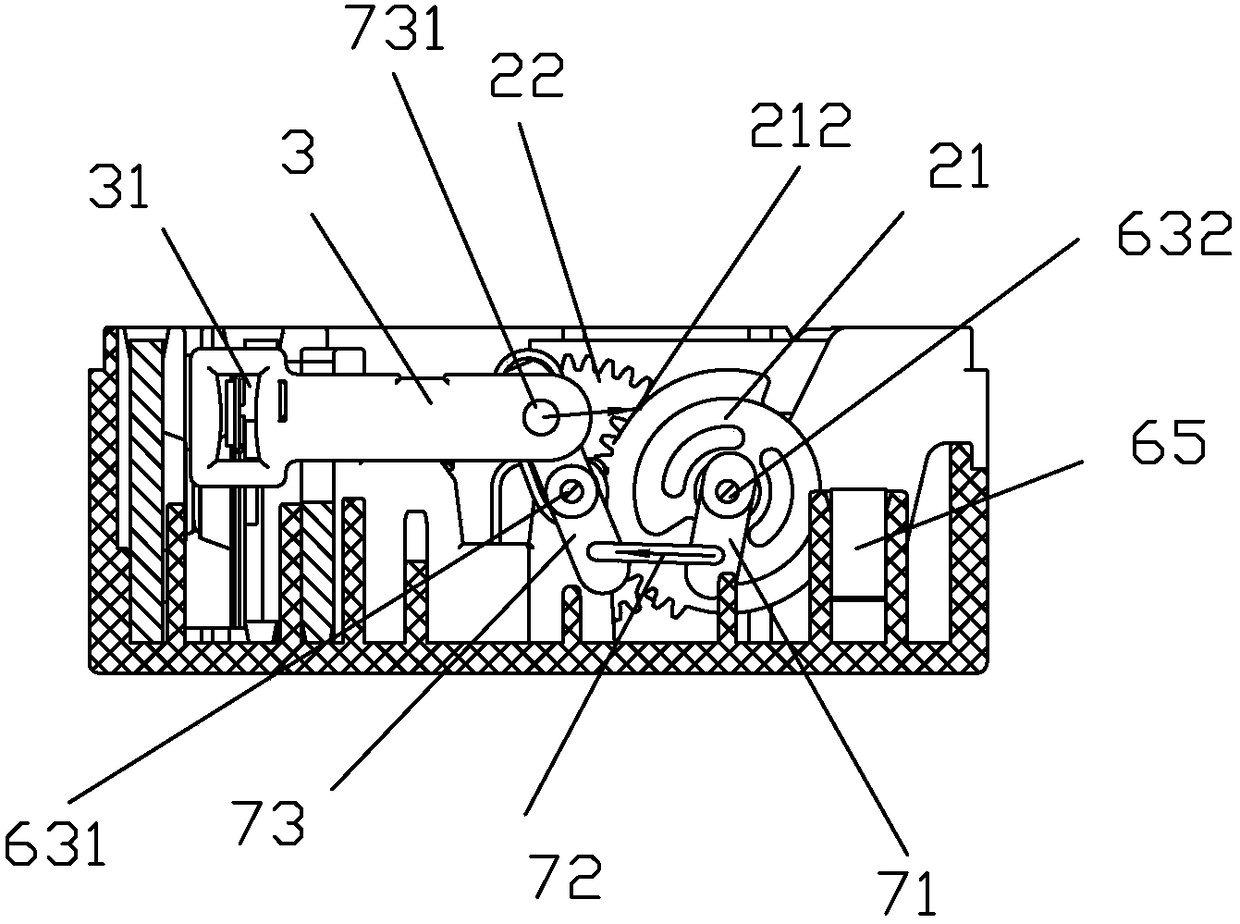

[0070] see Figure 1 to Figure 37 As shown, a motor relay of the present invention capable of quickly closing contacts includes a drive mechanism, a push card 3, a moving spring assembly 4 and a static spring assembly 5. In this embodiment, the drive mechanism adopts a motor 1 and a Linked gear reduction mechanism 2; the motor relay usually also includes a base 61 and a housing 62. The motor 1, gear reduction mechanism 2, moving spring assembly 4 and static spring assembly 5 are respectively mounted on the base 61, and the base 61 and the housing 62 connected; the moving spring assembly 4 and the static spring assembly 5 are installed in matching positions, one end of the push card 3 is matched with the moving spring assembly 4, and the other end of the push card 3 is linked with the gear reduction mechanism 2 , when the motor 1 is forward and reverse, the push card 3 drives the dynamic spring assembly 4 to realize the opening and closing of the dynamic and static contacts; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com