Integrated wire groove with hinge

A wire duct and hinge technology, applied in electrical components and other directions, can solve the problems of difficult disassembly, installation and maintenance operations, obstacles to wire harness maintenance and maintenance, and easy deformation of the groove cover, so as to reduce the probability of corrosion and facilitate maintenance. The effect of wiring, easy layout and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

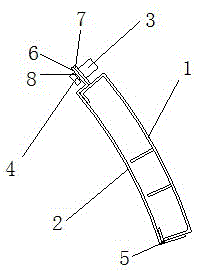

[0022] figure 1 It is a schematic diagram of the transverse section structure of the present invention. It can be seen from the accompanying drawings that the integrated trunking with hinge 5 is installed on the car body of the railway passenger car and is used for wiring of the railway passenger car. The trunking includes a groove body 1 and a The tank cover 2, the tank body 1 and the tank cover 2 are connected by a hinge 5, the tank cover 2 can rotate around the hinge 5, and the free edge of the tank body 1 and the tank cover 2 is connected. When the present invention is in use, the tank body 1 is installed on the car body of the railway passenger car, and the tank cover 2 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com