A combine harvester and its compound cleaning system

A cleaning and suction fan technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of affecting the cleaning quality, grain pollution, discharge, and can only be stored in the separation cylinder, so as to ensure cleaning Effect, strong processing ability, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

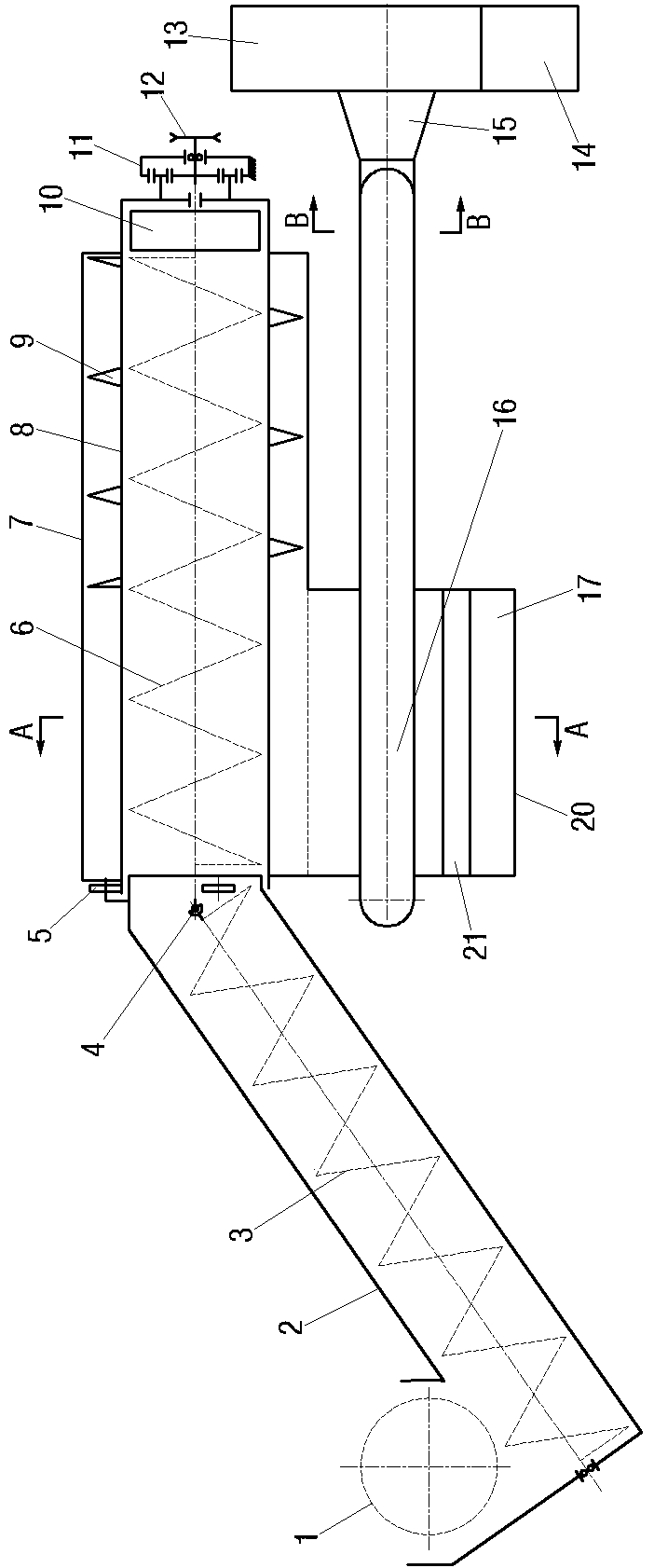

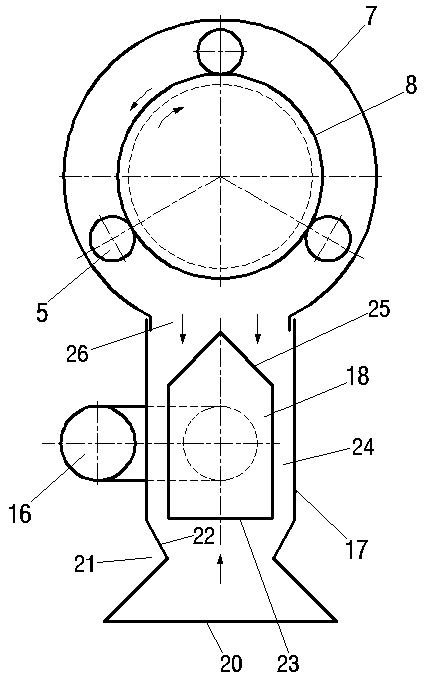

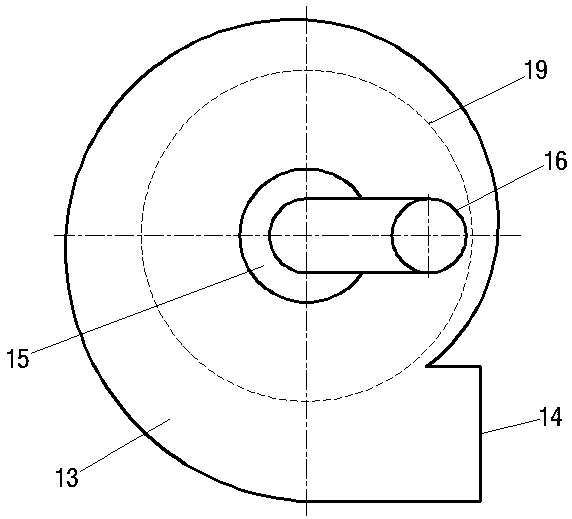

[0026] An example of a combine harvester such as Figure 1~Figure 4 As shown, it includes a frame (not shown in the figure), and a threshing device (not shown in the figure) and a compound cleaning system are arranged on the frame, and the compound cleaning system includes the third pusher 1, the second pusher 3 and the separation drum 8, the mixture of grains, glumes, and broken stalks threshed by the threshing device is transported to the bottom of the second auger 3 under the action of the third auger 1. The second auger 3 is arranged obliquely, and a material conveying pipeline 2 is arranged outside it. Under the rotation of the second auger 3 , the material to be cleaned is lifted to the material inlet of the separation drum 8 . The separation drum 8 is set horizontally, and its other end is provided with a grass outlet 10. The separation drum 8 is provided with a first pusher 6, and the rotation shafts of the first pusher 6 and the second pusher 3 pass through a coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com