Roaster

A roasting machine and baking technology, applied in the application, food processing, food science and other directions, can solve the problems of the dust bucket 12 becoming hot, and the dust bucket cannot be replaced quickly, so as to avoid hot, improve efficiency, and be easy to replace. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

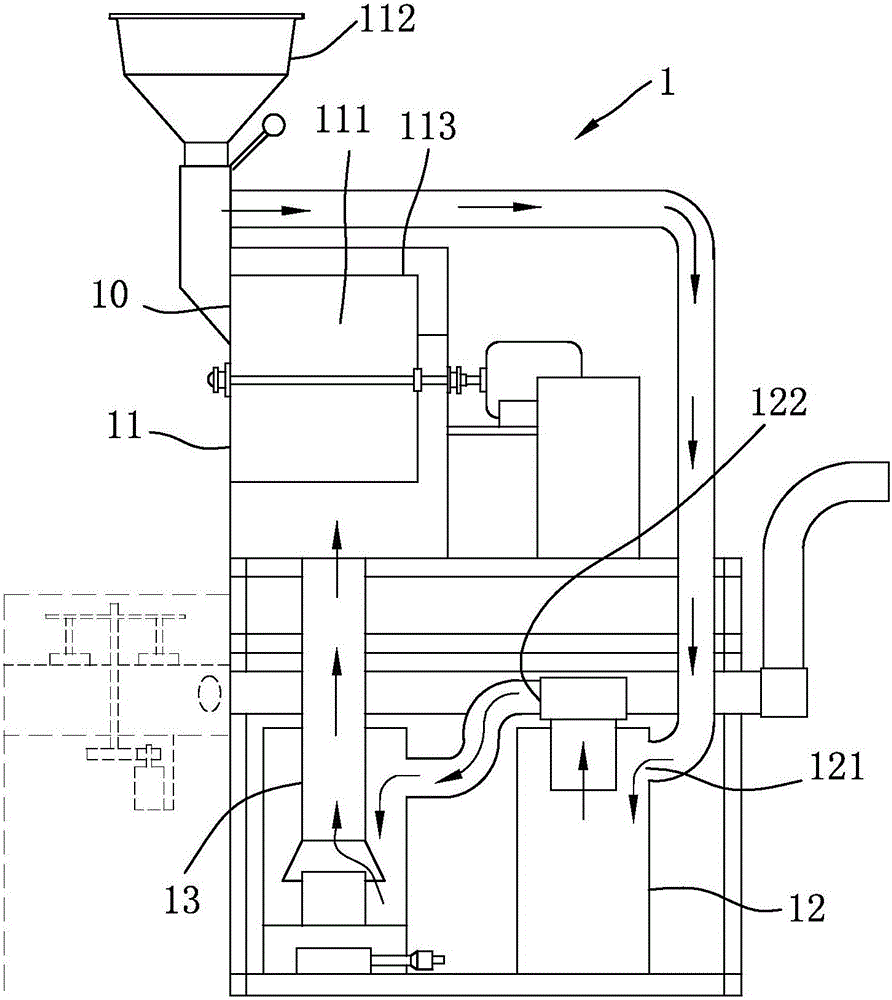

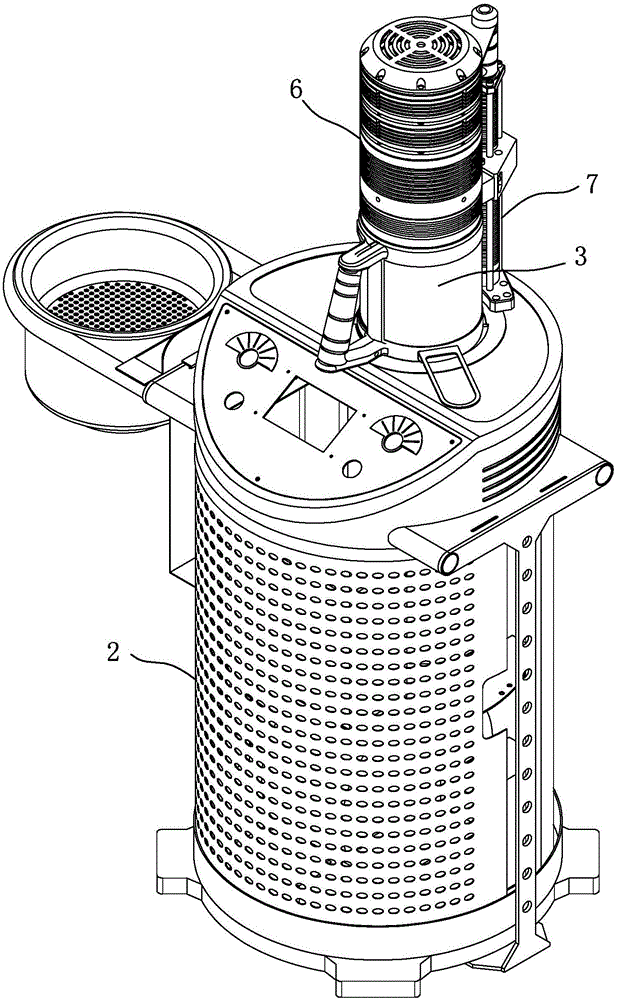

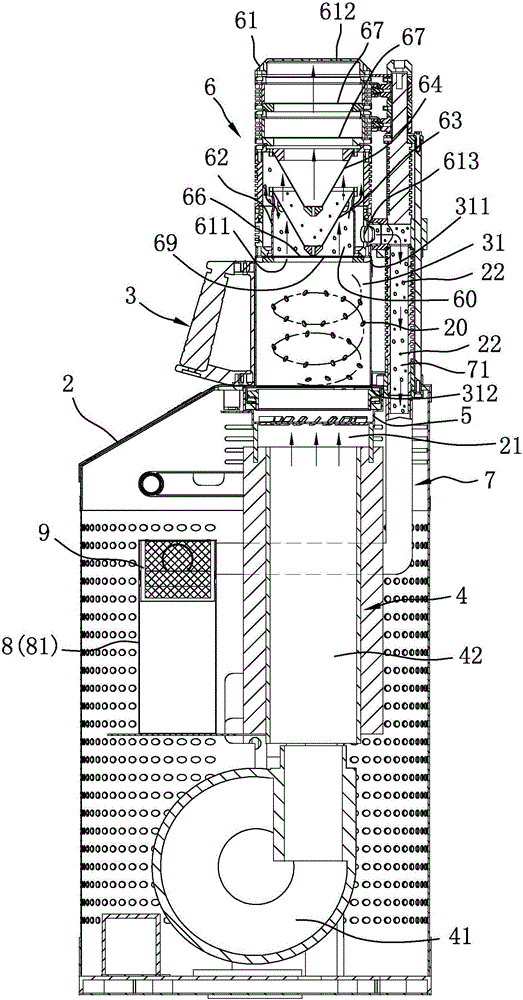

[0028] refer to figure 2 , image 3 and Figure 4 , an embodiment of the roaster of the present invention is suitable for roasting a to-be-baked object 20 . The to-be-baked object 20 is, for example but not limited to, green coffee beans or green chocolate beans.

[0029] The roaster includes a frame 2, a carrying device 3, a hot air supply device 4, a flow guide seat 5, a first filter device 6, a connecting device 7, a collecting device 8, and a second filter device 9 .

[0030] The carrying device 3 is removably arranged on the frame 2, and includes a fixing base 32, a holding frame 33 connected to the fixing base 32, a cylinder 34 arranged in the holding frame 33, and A carrier 35 is located at the bottom of the cylinder 34 and has a plurality of perforations 351 for carrying the to-be-baked object 20 . The carrier 35 and the cylinder 34 def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com