Collecting pipe for heat exchanger and heat exchanger

A heat exchanger and header technology, applied in the field of heat exchange equipment, can solve problems such as operational safety accidents, external heating, etc., and achieve the effect of increasing the contact area, improving the efficiency of heat exchange, and improving the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

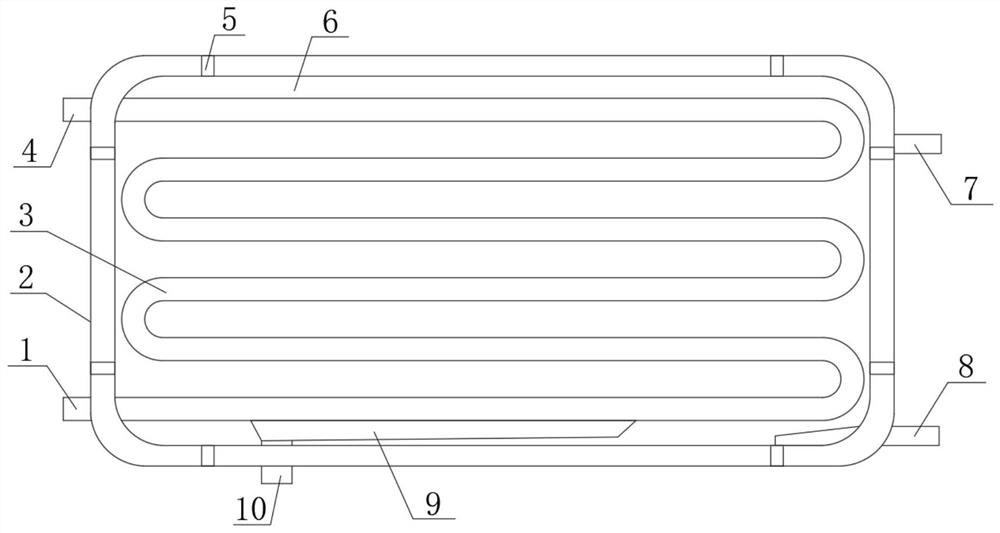

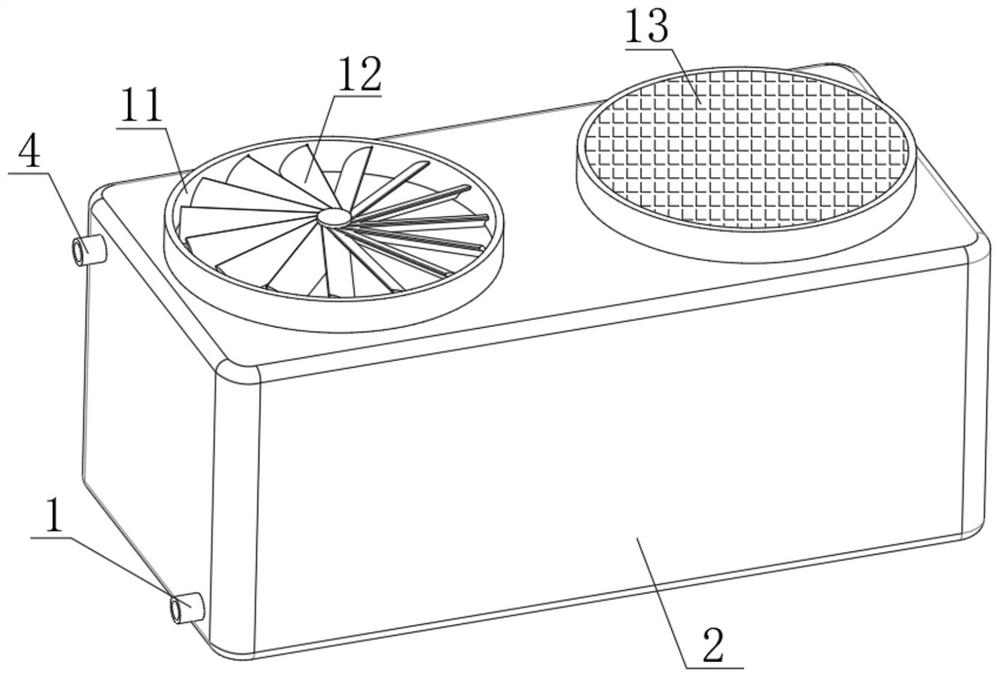

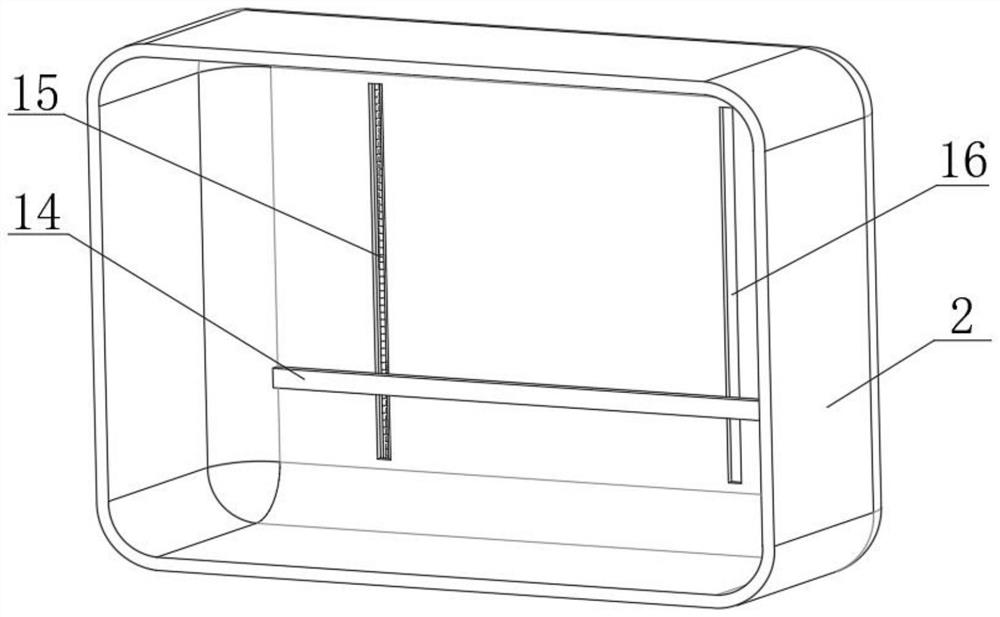

[0029] A header and heat exchanger for heat exchangers such as Figure 1-3 As shown, including the main chassis 2, both ends of the top inner wall and the bottom inner wall of the main chassis 2 are fixed with vertically arranged fixed connecting rods 5, and the fixed connecting rods 5 at the top position and the bottom position are fixed with the same The heat exchange inner chassis 6 arranged horizontally, the heat exchange coil 3 arranged horizontally is fixed between the inner walls of both ends of the heat exchange inner chassis 6, the bottom of one end of the main chassis 2 is provided with a first hole, and the first hole is sleeved with The heat exchange inlet 1 is arranged horizontally, one end of the heat exchange inlet 1 communicates with the bottom of the heat exchange coil 3, a second hole is opened on the top of one end of the main chassis 2, and the inner wall of the second hole is sleeved with The heat exchange liquid outlet pipe 4 is arranged horizontally, and...

Embodiment 2

[0033] A header and heat exchanger for heat exchangers such as Figure 1-4 As shown, the outer peripheral wall of the heat exchange coil 3 is provided with spherical tubes 17 arranged in a horizontal array, and the spherical tubes 17 communicate with the interior of the heat exchange coil 3 .

[0034] When this embodiment is in use, in Embodiment 2, on the basis of Embodiment 1, spherical tubes 17 are arranged on the outer wall of the heat exchange coil 3 in an array. The contact area of the external water improves the overall heat transfer effect and improves the heat transfer efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com