A rolling bending machine for s spring

A technology of a roll bender and a machine base, applied in the mechanical field, can solve the problems of inability to realize the automatic feeding and automatic unloading of the S spring, the inability to ensure the uniformity of the bending of the S spring, and the inability to adjust the bending degree of the S spring, etc. To achieve the effect of preventing burning, reducing the occupied volume, and eliminating the need for manual cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

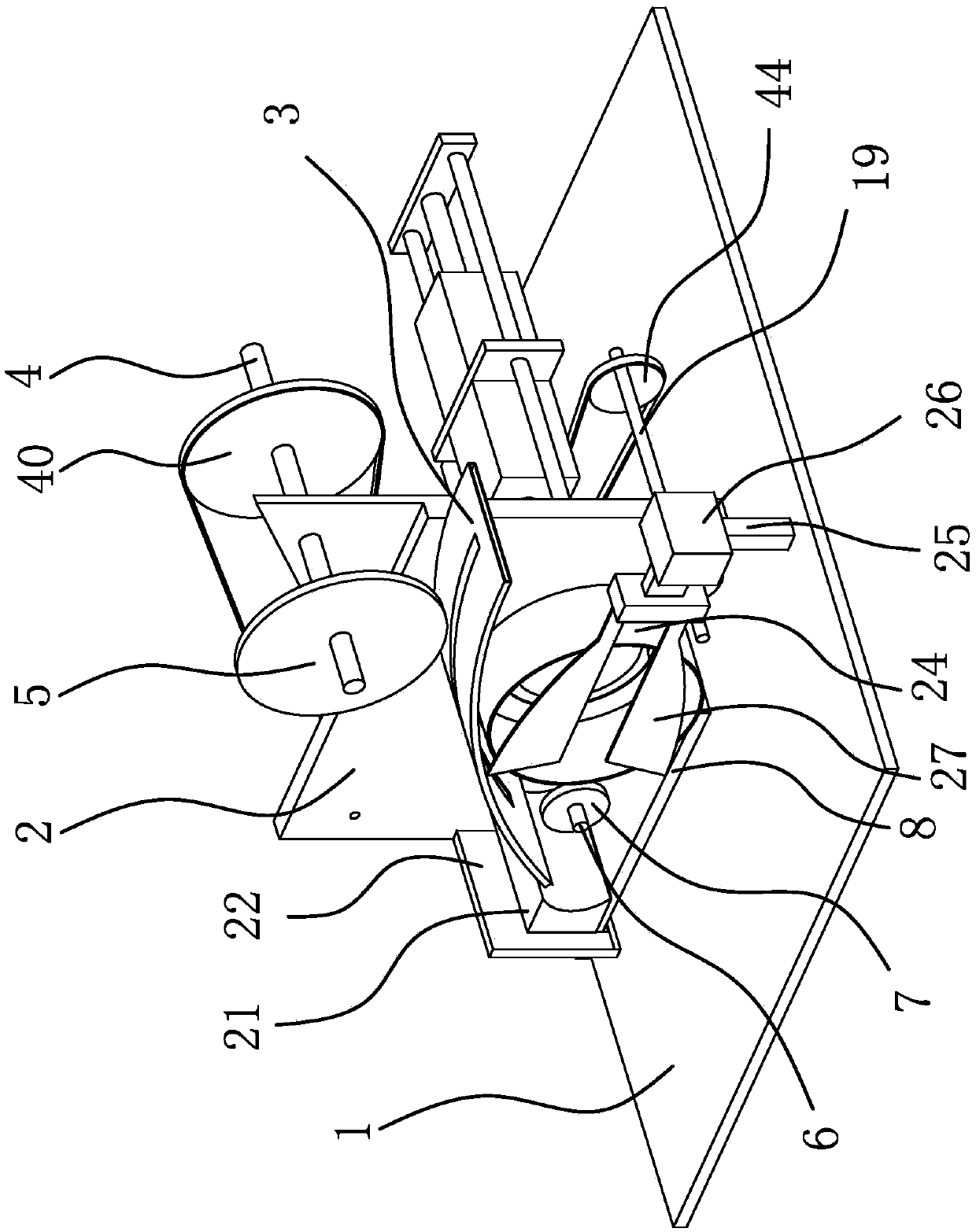

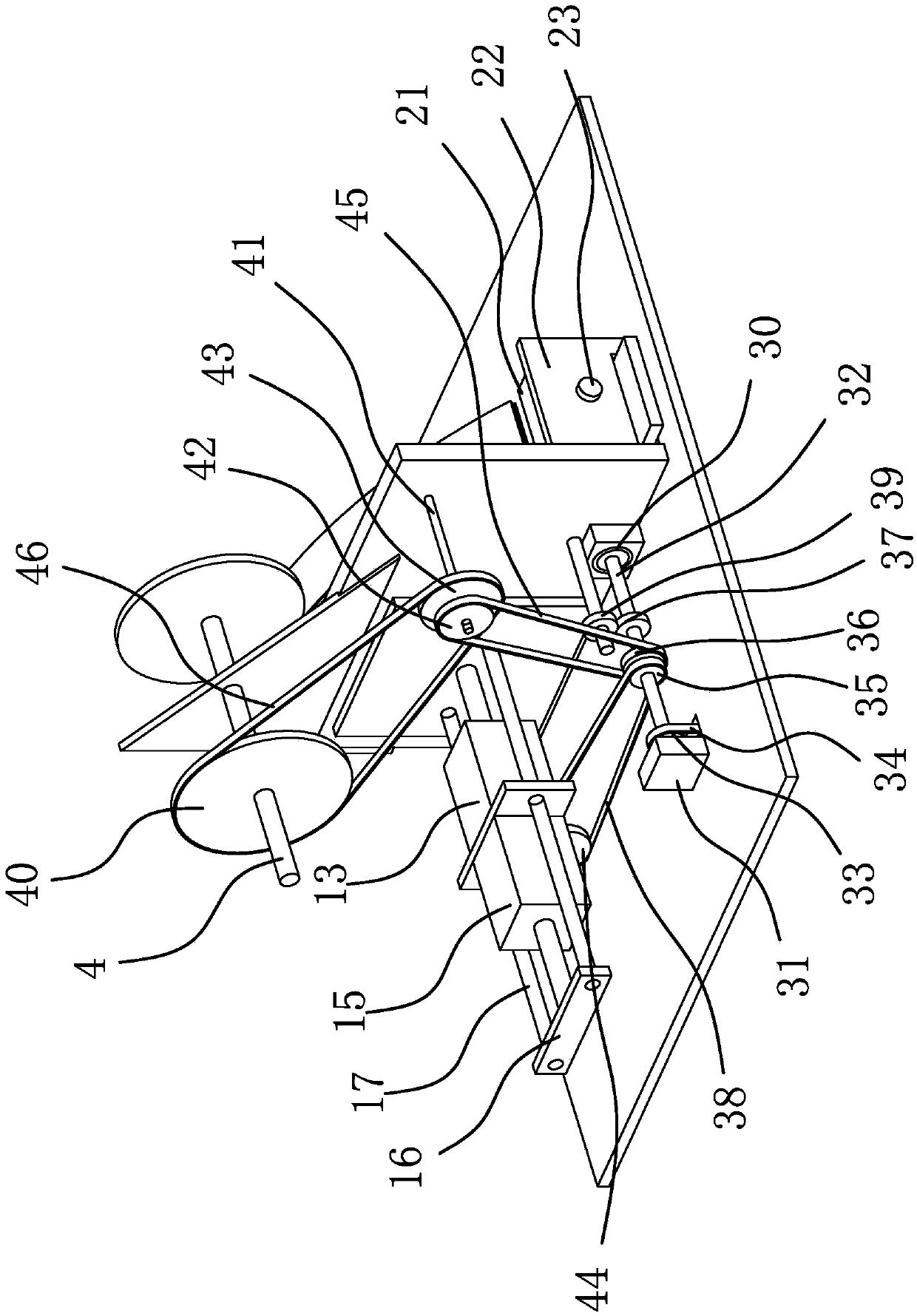

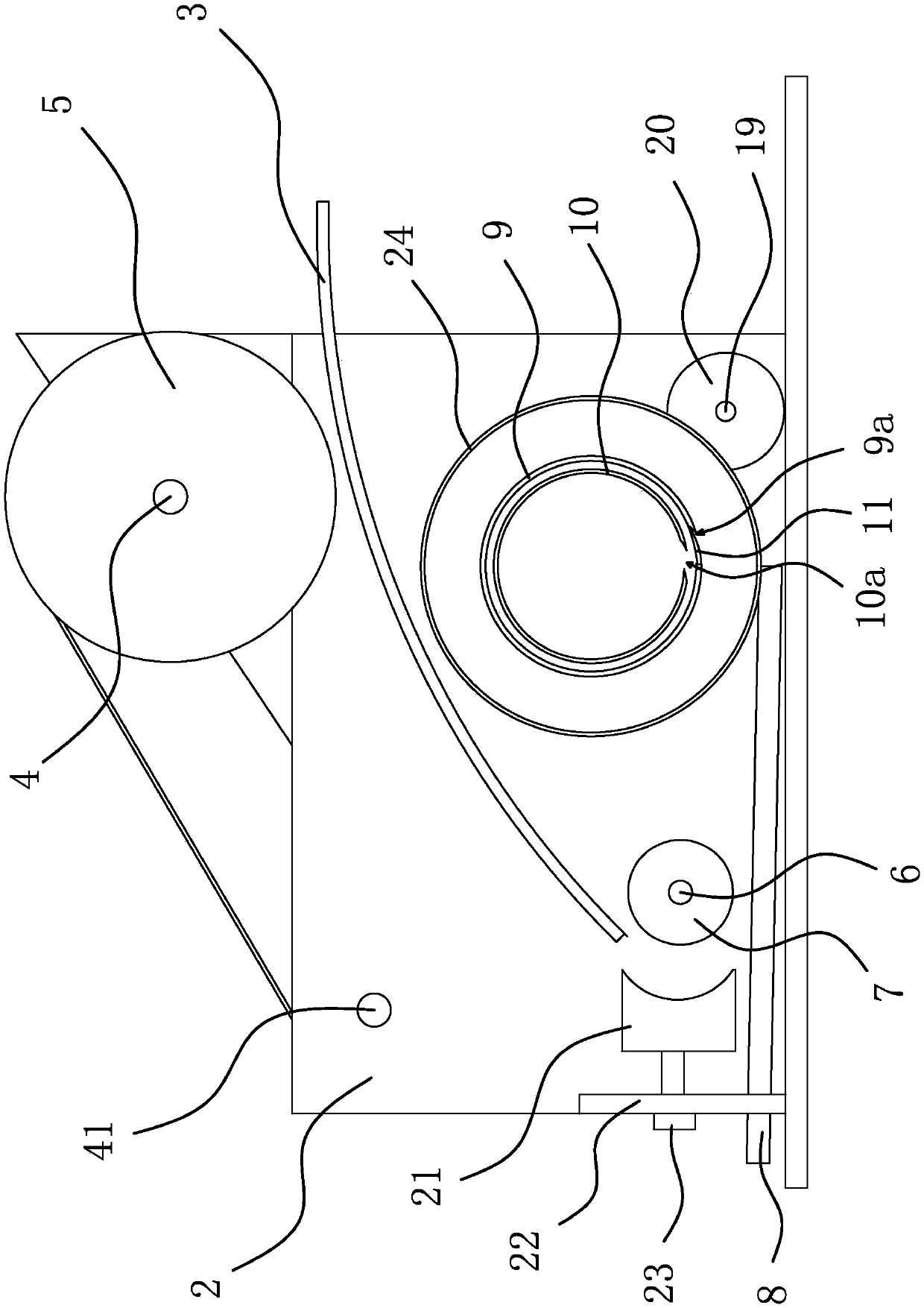

[0034] Such as figure 1 As shown, a rolling bending machine of an S spring includes a machine base 1 and a riser 2 vertically welded and fixed on the machine base 1. One side of the riser 2 is welded and fixed with a conveying rail 3 with a conveying channel inside, and the conveying The rail 3 is arc-shaped, and there is a long hole on the conveying rail 3. The vertical plate 2 is fixed with a rotating shaft 4 by means of circumferential rotation and axial fixing. The gear 5 and the traveling gear 5 are located above the conveying rail 3 and the teeth of the traveling gear 5 extend into the elongated holes. The vertical plate 2 is also fixed with a rotating shaft 2 6 by means of circumferential rotation and axial fixing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com