Detachable thermal insulation device for railway tank car

A heat preservation device and tank car technology, which is applied in the field of railway tank car manufacturing, can solve problems such as difficulties in maintenance of heat preservation devices, and achieve the effects of convenient installation, cost reduction, and improved heat preservation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

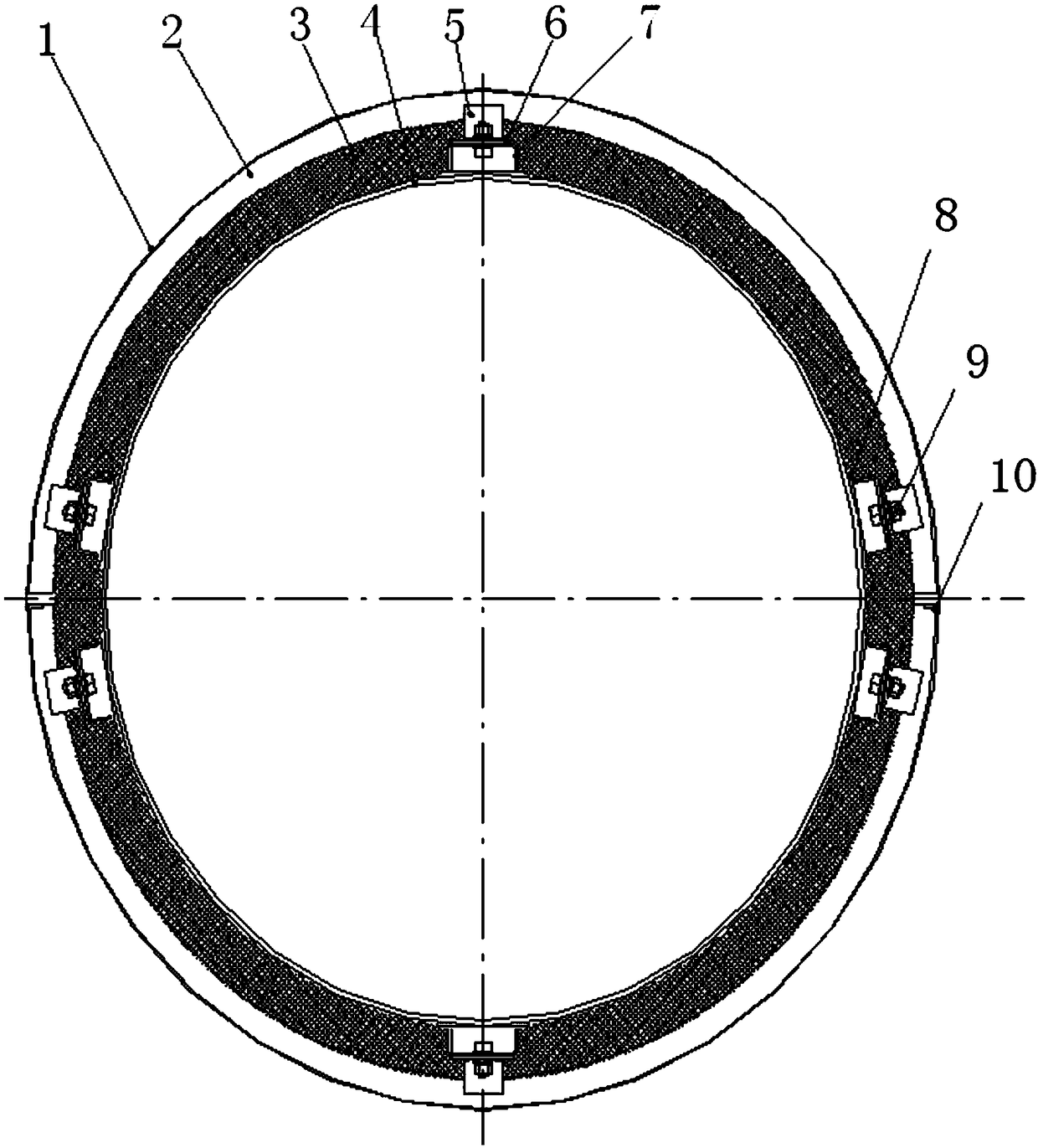

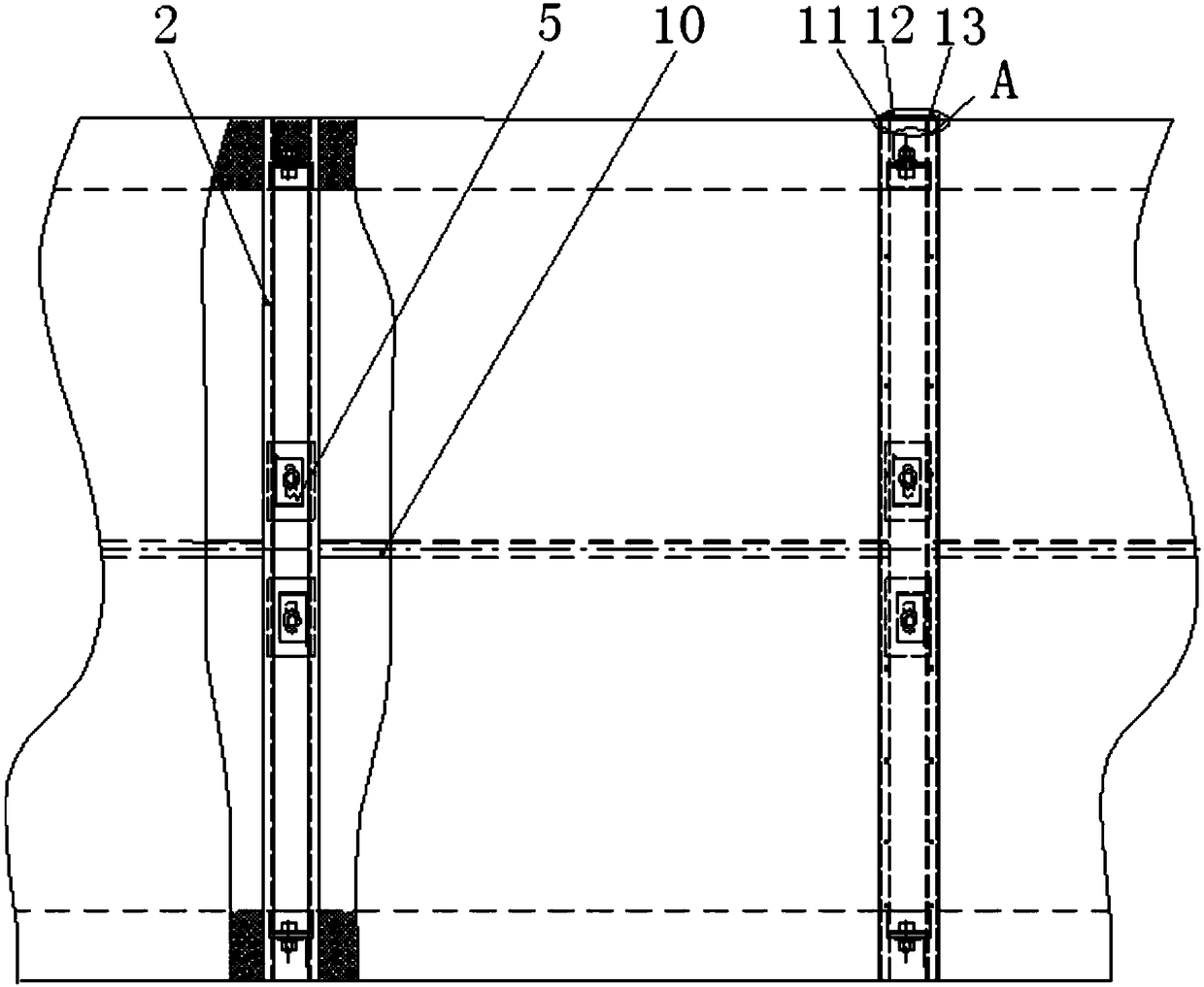

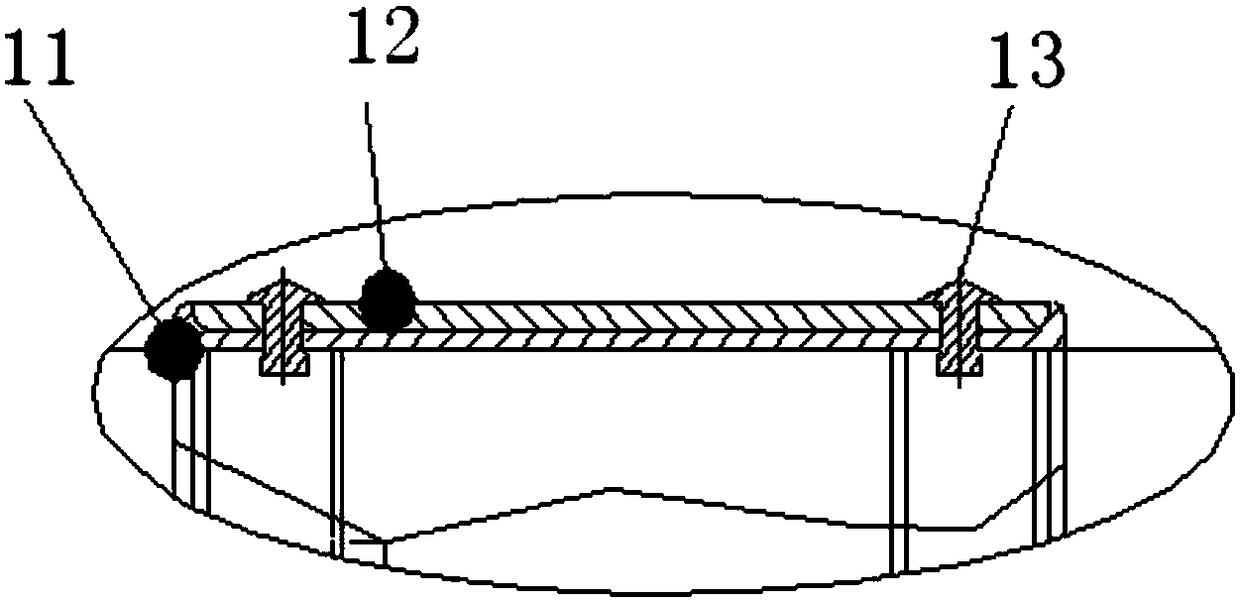

[0027] The detachable thermal insulation device of the present invention is a novel thermal insulation structure of a railway tank car, and has considerable advantages over the original thermal insulation device. The structure is composed of multiple insulation shell sections, and each insulation shell section includes upper and lower flaps. Each insulation shell is welded by the insulation shell plate and the ring frame. The heat-insulation shell plate overlaps the connection form of the lower heat-insulation shell plate to form a ring-shaped sealing structure, which effectively prevents rainwater from entering. In order to ensure the rigidity of the thermal insulation shell at the lap joint, angle iron supports along the longitudinal direction of the tank body are welded on the circumferential frame at the lap joint. There is a certain gap between the two adjacent sections of the insulation shell, the purpose of which is to reserve the working space for the bolt fasteners, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com