One-directional transporting device for workpieces between assembly lines

A technology of handling device and assembly line, which is used in transportation and packaging, conveyor control device, conveyor objects, etc., can solve the problems of occupying limited space in factories, time-consuming and labor-intensive, and unfavorable enterprise development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The invention provides a device for conveying workpieces in the same direction between assembly lines. This device has a simple mechanical structure and low production cost, and is more in line with actual industrial production needs.

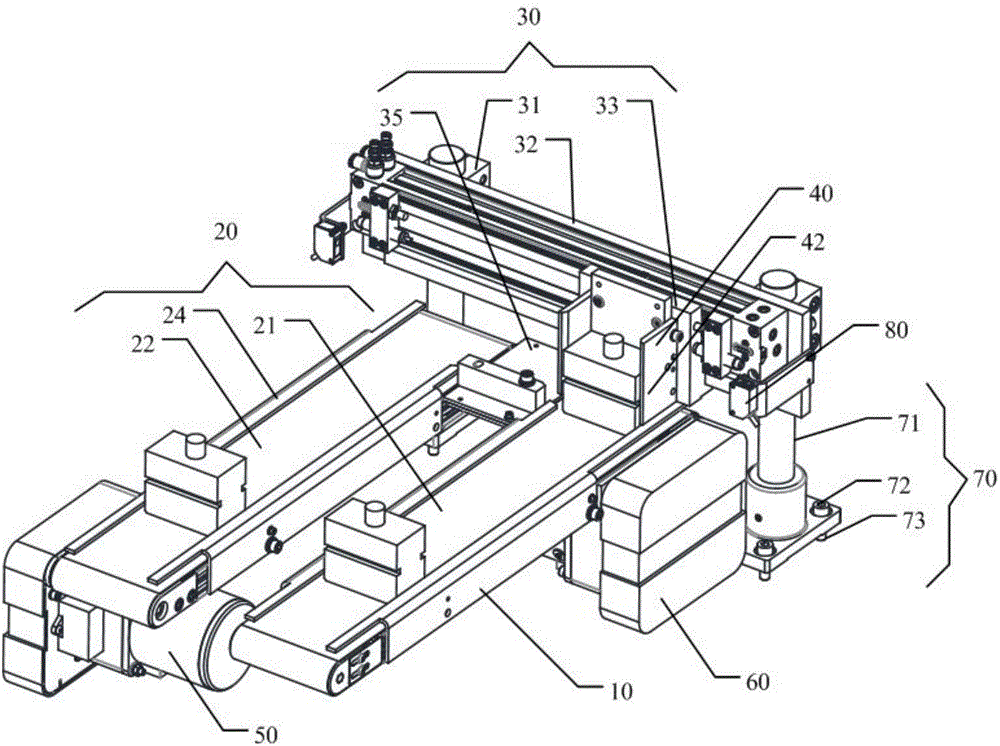

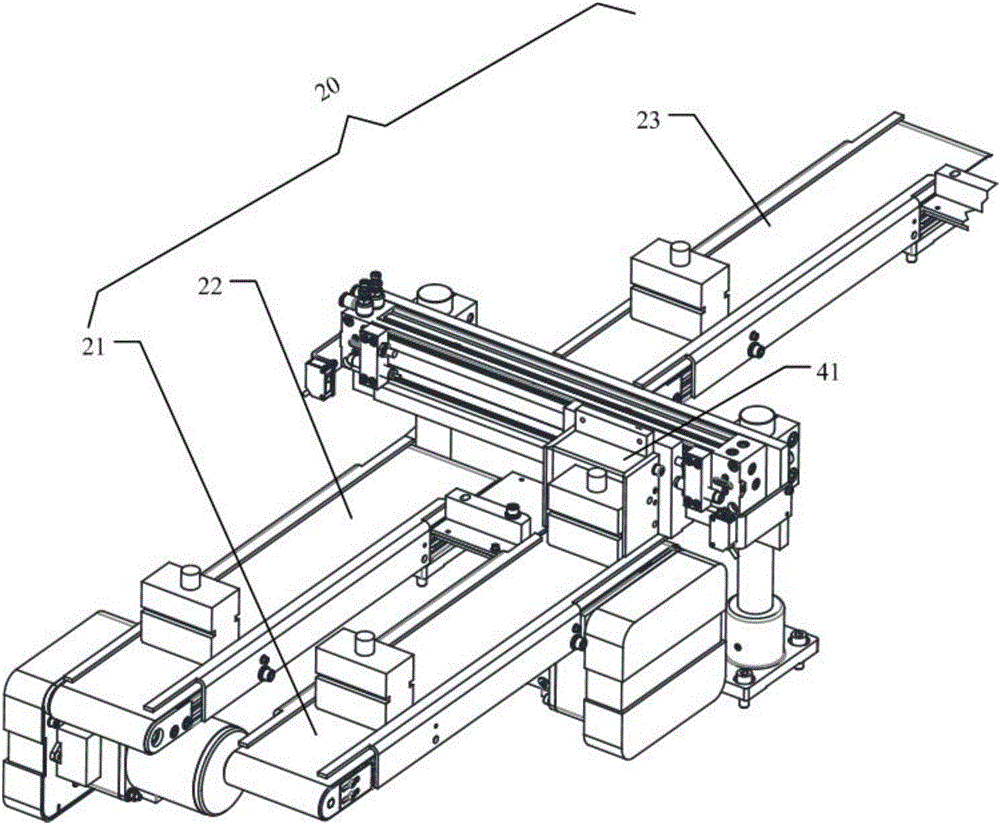

[0048] see figure 1 with figure 2 , an embodiment of the same-direction handling device for workpieces between assembly lines in the present invention, comprising:

[0049] Frame 10, connecting conveyor belt 20, horizontal feed mechanism 30, workpiece fixture 40, motor 50, lifting frame 70 and photoelectric sensor 80;

[0050] The connecting conveyor belt 20 is assembled on the frame 10;

[0051] The connecting conveyor belt 20 includes a first connecting conveyor belt 21 and a second connecting conveyor belt 22;

[0052] The first connecting conveyor belt 21 is provided with a clockwise or counterclockwise rotating belt;

[0053] The second connecting conveyor belt 22 is provided with a belt that is opposite to the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com