Buckle folding unit and sheet-fed folding machine including buckle folding unit

A folding mechanism and barrier-type technology, applied in the field of sheet folders, can solve the problems of lower quality folding or refolding, difficult guidance, and sheets cannot be reliably conveyed, and achieve the effect of improving folding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

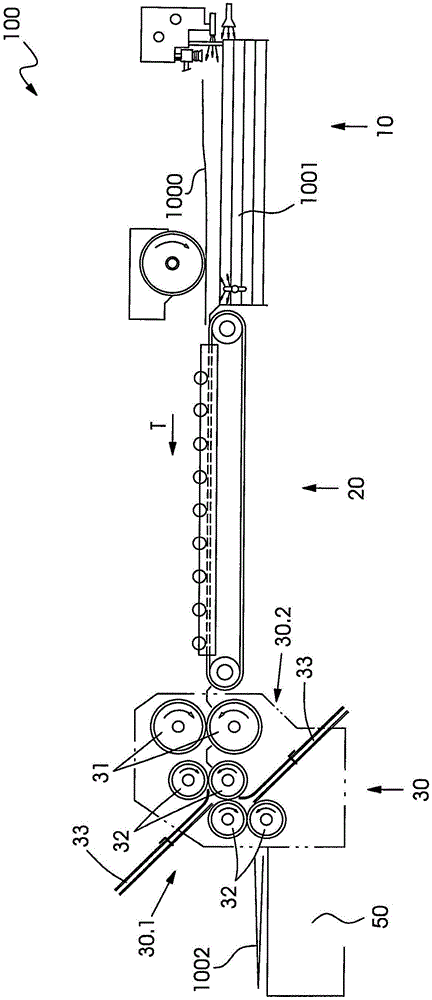

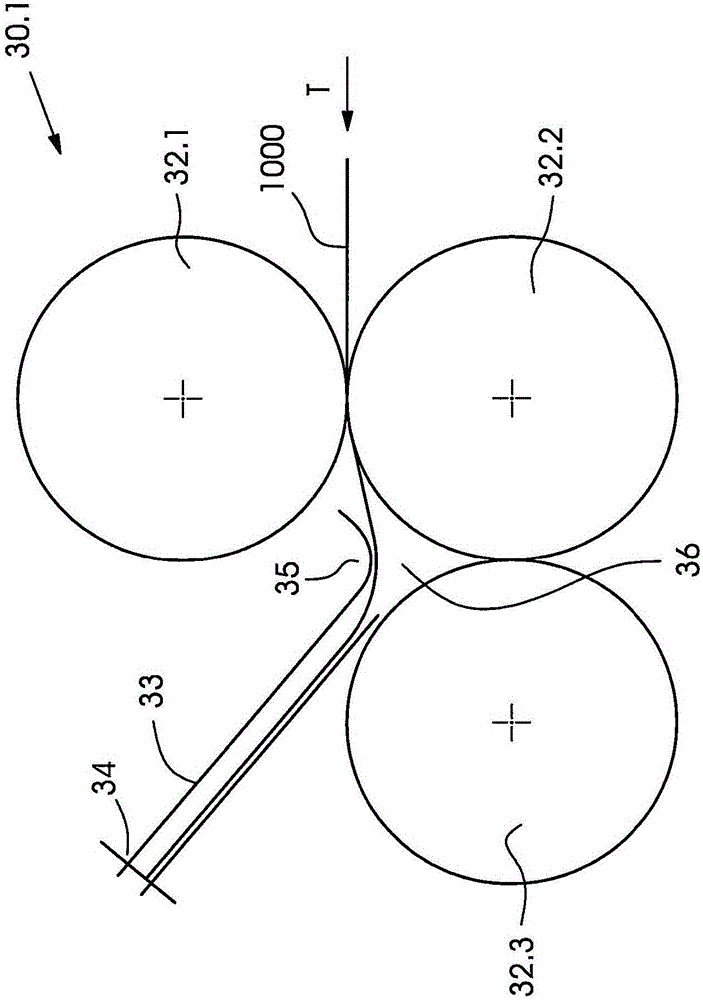

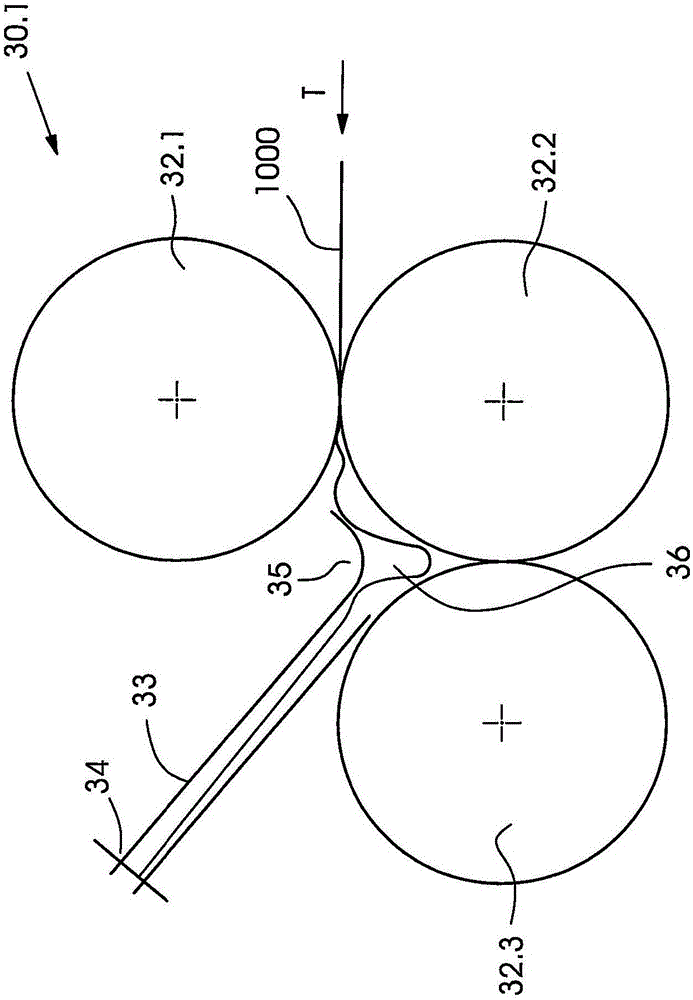

[0027] figure 1 Shown is a sheet folder 100 with a sheet feeder 10, a supply station 20 with an orientation table, a fence folding station 30 with two fence folding mechanisms 30.1 and 30.2, and a signature take-up 50 . In the area of the sheet feeder 10 the individual sheets 1000 are separated from the sheet stack 1001 and transferred to a supply station 20 with an orientation station. The individual sheets 1000 are supplied from the supply station 20 along the sheet transport direction T to the fence folding station 30 . In this case, the sheet 1000 can be processed by the front cutter shaft 31 in preparation for the folding. The actual processing takes place in the fence folding station 30 , ie the folding of the sheet 1000 takes place by means of the folding fence 33 cooperating with the folding rollers 32 . The structure of the barrier folding station 30 is described further below with reference to the other figures. The sheets 1000 folded in the barrier folding sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com