Automatic tumble annealing equipment for glasses

A technology of automatic turning and annealing equipment, which is applied in the field of annealing equipment for glass products, can solve the problems of long furnace chamber length and large occupied space, and achieve the effects of uniform heating, reduced space and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

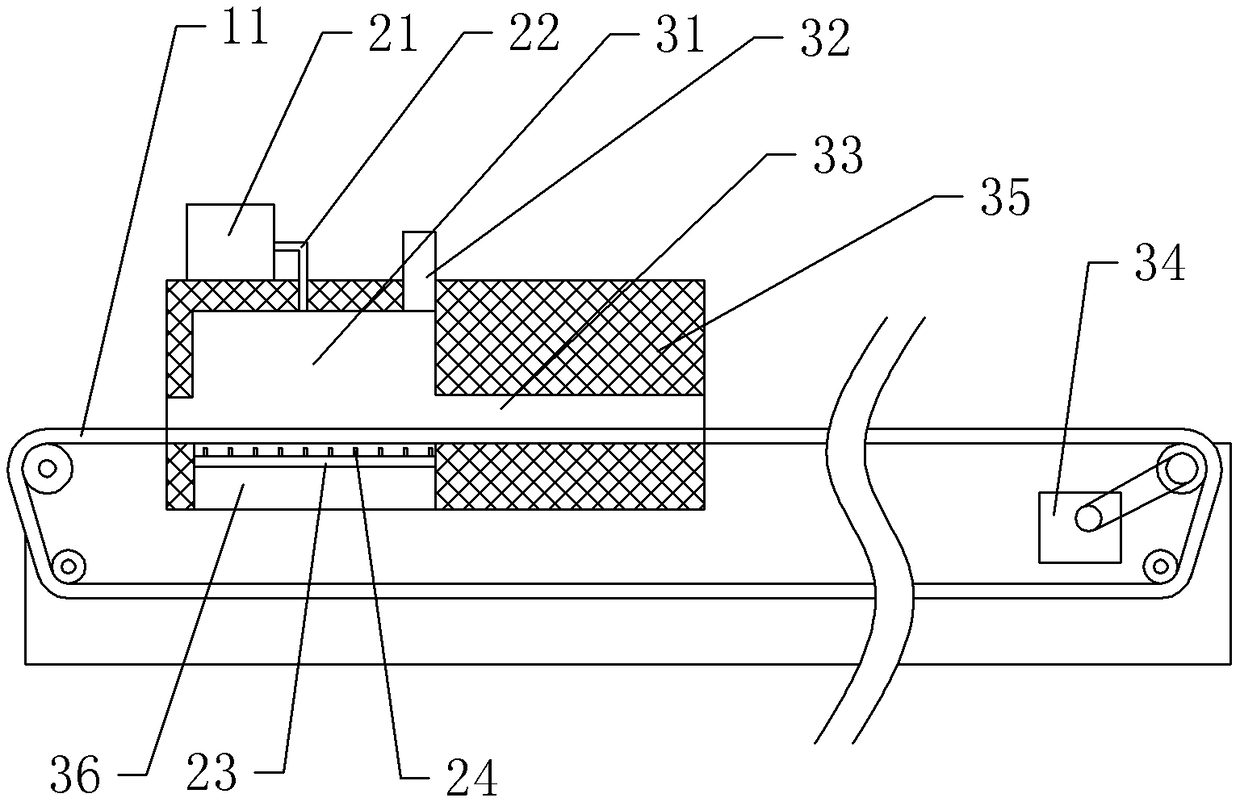

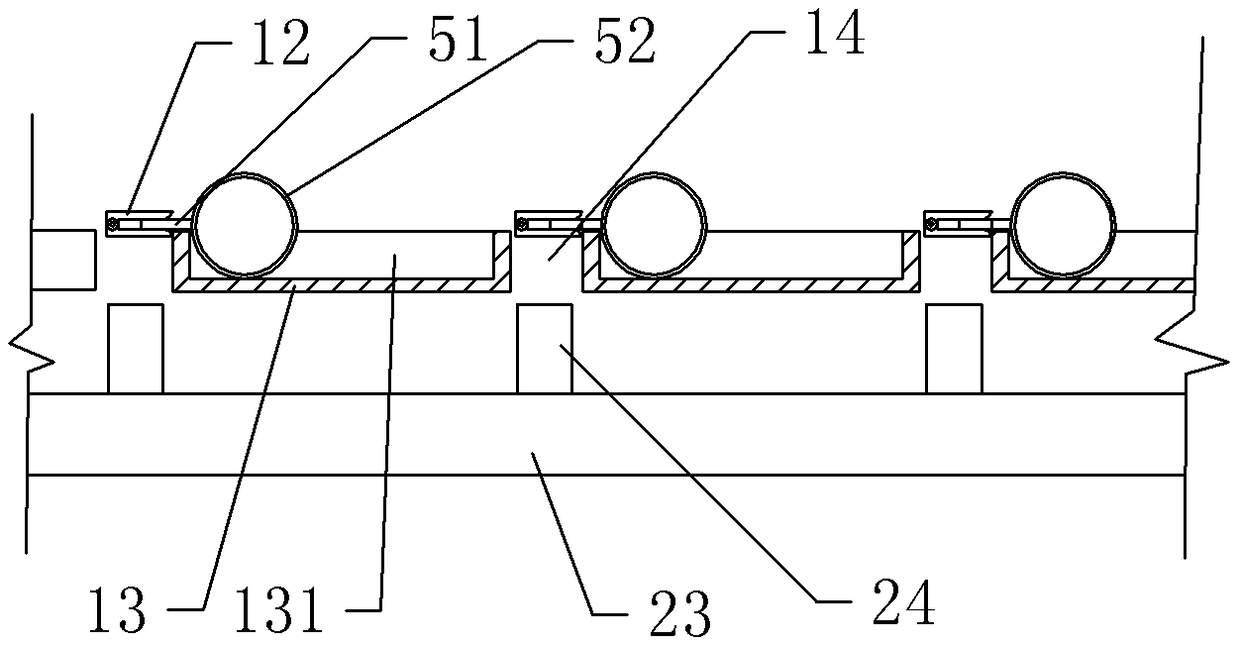

[0018] The reference signs in the accompanying drawings of the description include: conveyor chain 11, first clamping block 12, material plate 13, groove 131, gap 14, air pump 21, air intake pipe 22, air injection pipe 23, spray nozzle 24, furnace cavity 31, Smoke exhaust channel 32, thermal insulation channel 33, servo motor 34, upper thermal insulation layer 35, combustion chamber 36, cup handle 51, glass cup 52.

[0019] Such as figure 1 and figure 2The shown automatic flip-type annealing equipment for glass includes a frame, a furnace body arranged on the frame, and a combustion chamber 36 for installing a burner and a furnace chamber 31 above the combustion chamber 36 are arranged in the furnace body , The length of the combustion chamber 36 is equal to the length of the furnace cavity 31. The left end of the furnace body is provided with a furnace body inlet, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com