Anti-deflection rock drilling control system

A control system and anti-deflection technology, applied in the field of hydraulic control, can solve problems such as blast hole failure, rock drilling process hazards, difficult to achieve deflection prevention control, etc., to avoid drilling deflection, sensitive response, and comprehensive reference control factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

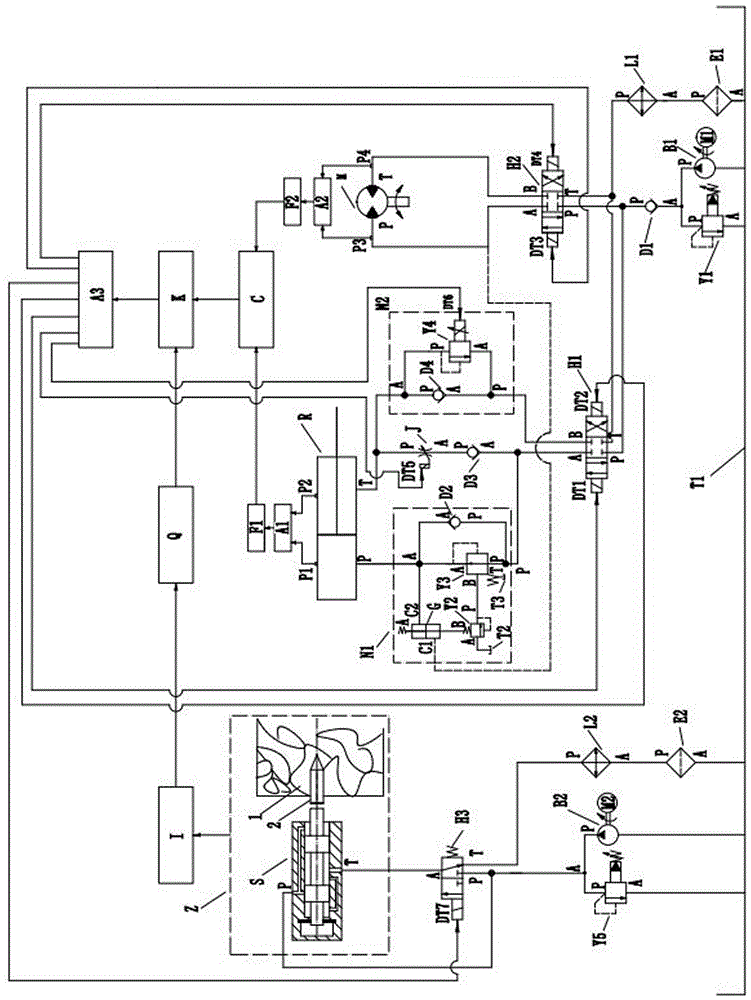

[0019] As shown in accompanying drawing 1, an anti-deflection rock drilling control system of the present invention includes a power mechanism, an actuator, a control valve, and an electrical system; wherein:

[0020] The power mechanism includes a fuel tank, one-way pumps B1, B2 and motors M1, M2. The one-way pumps B1 and B2 are driven by the motors M1 and M2 to supply hydraulic oil to the system;

[0021] The control valve includes three-position four-way electromagnetic directional valve H1, H2, two-position three-way electromagnetic directional valve H3, pilot relief valve Y1, Y5, one-way valve D1, D3, proportional throttle valve J, propulsion pressure control Valve N1, propulsion back pressure valve N2, filters E1, E2, coolers L1, L2. Pilot-operated relief valves are respectively bypassed in the main oil circuit to limit the oil pressure of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com