A commercial gas hob and its preparation process

A gas furnace, a commercial technology, applied in the field of commercial gas hobs and its preparation process, can solve the problems affecting the market competitiveness of products, uneven leg arrangement, and furnace legs cannot be supported upright, so as to achieve industrial standard production , It is conducive to full combustion, and the effect of improving processing quality and processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

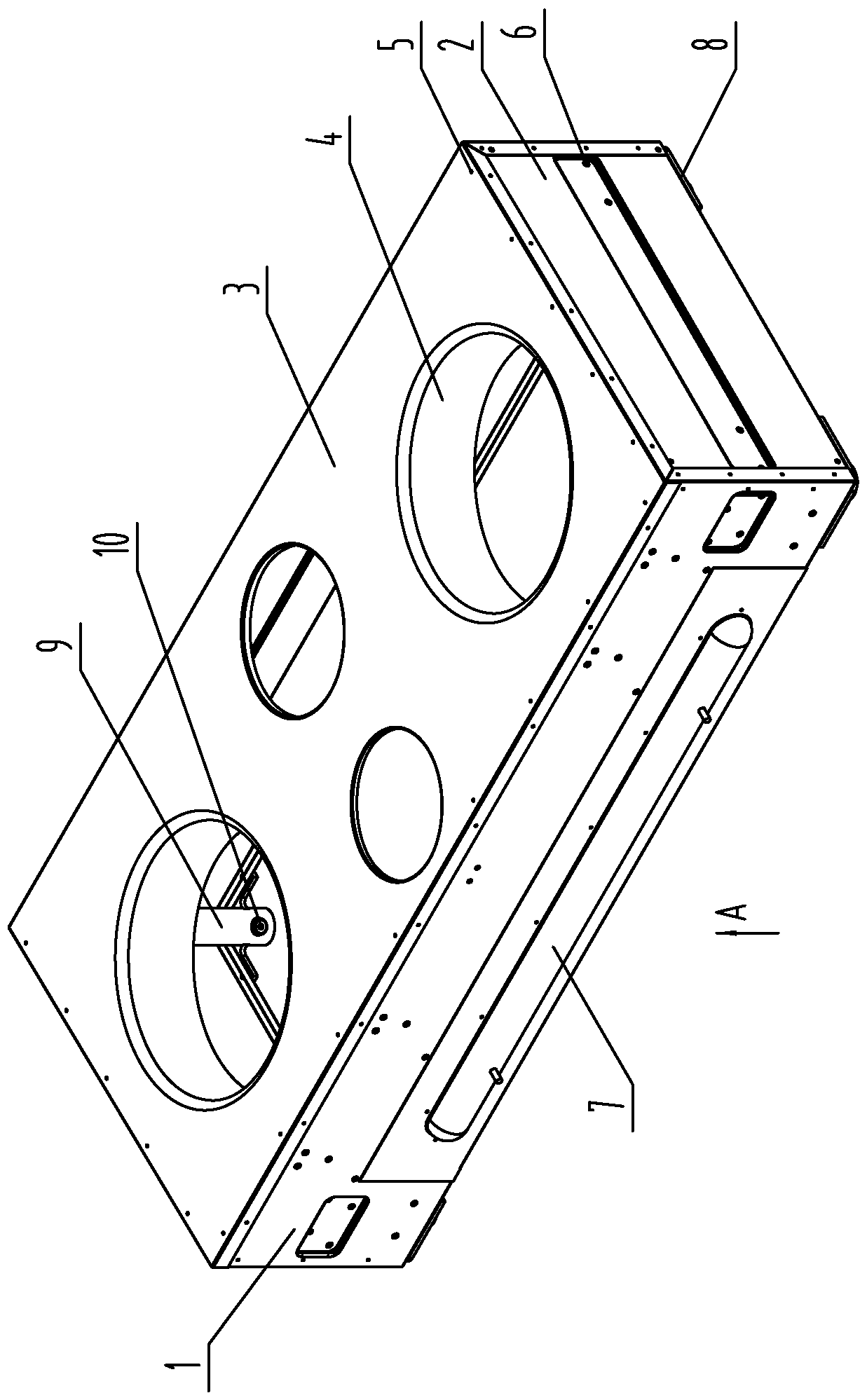

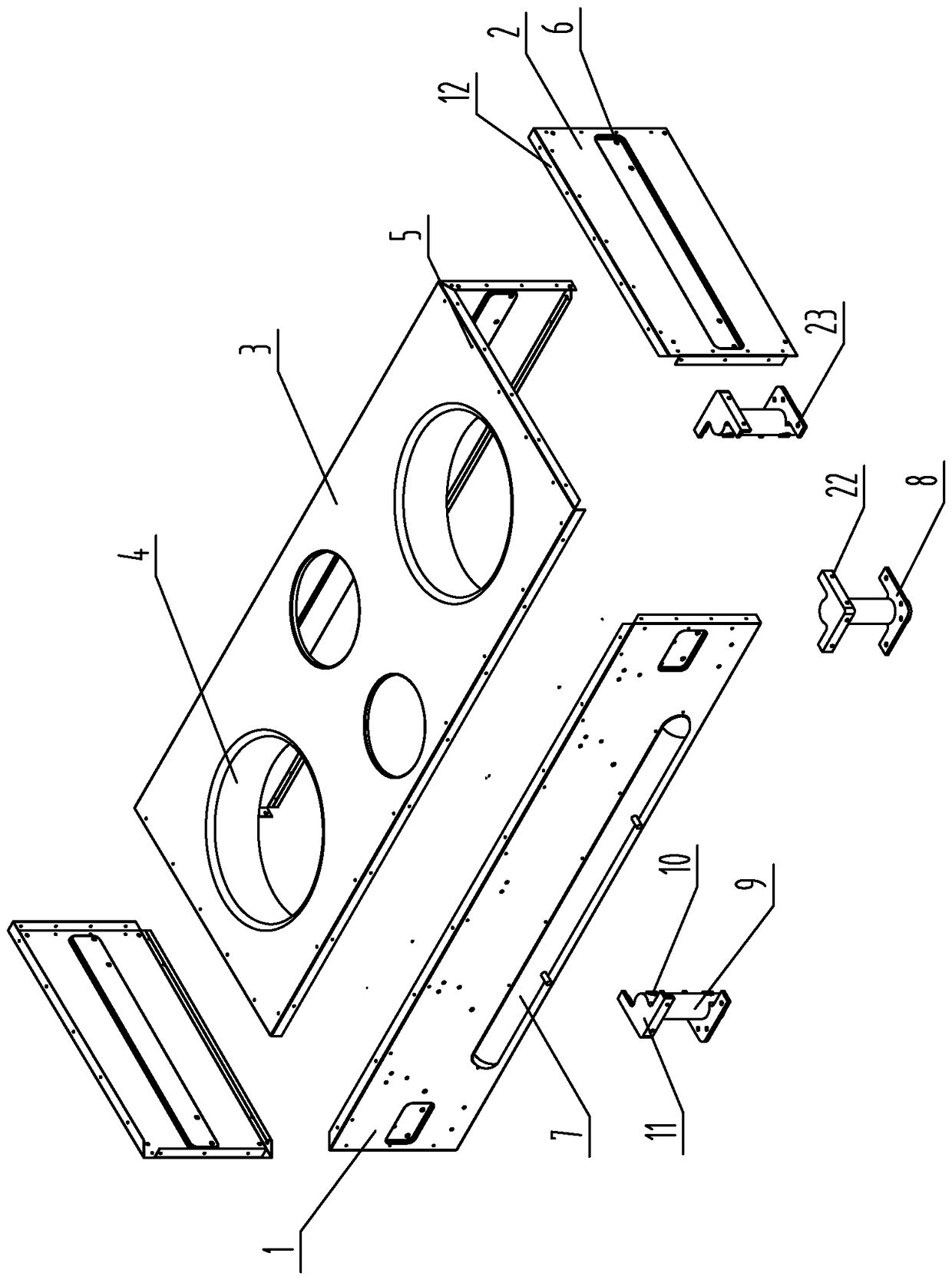

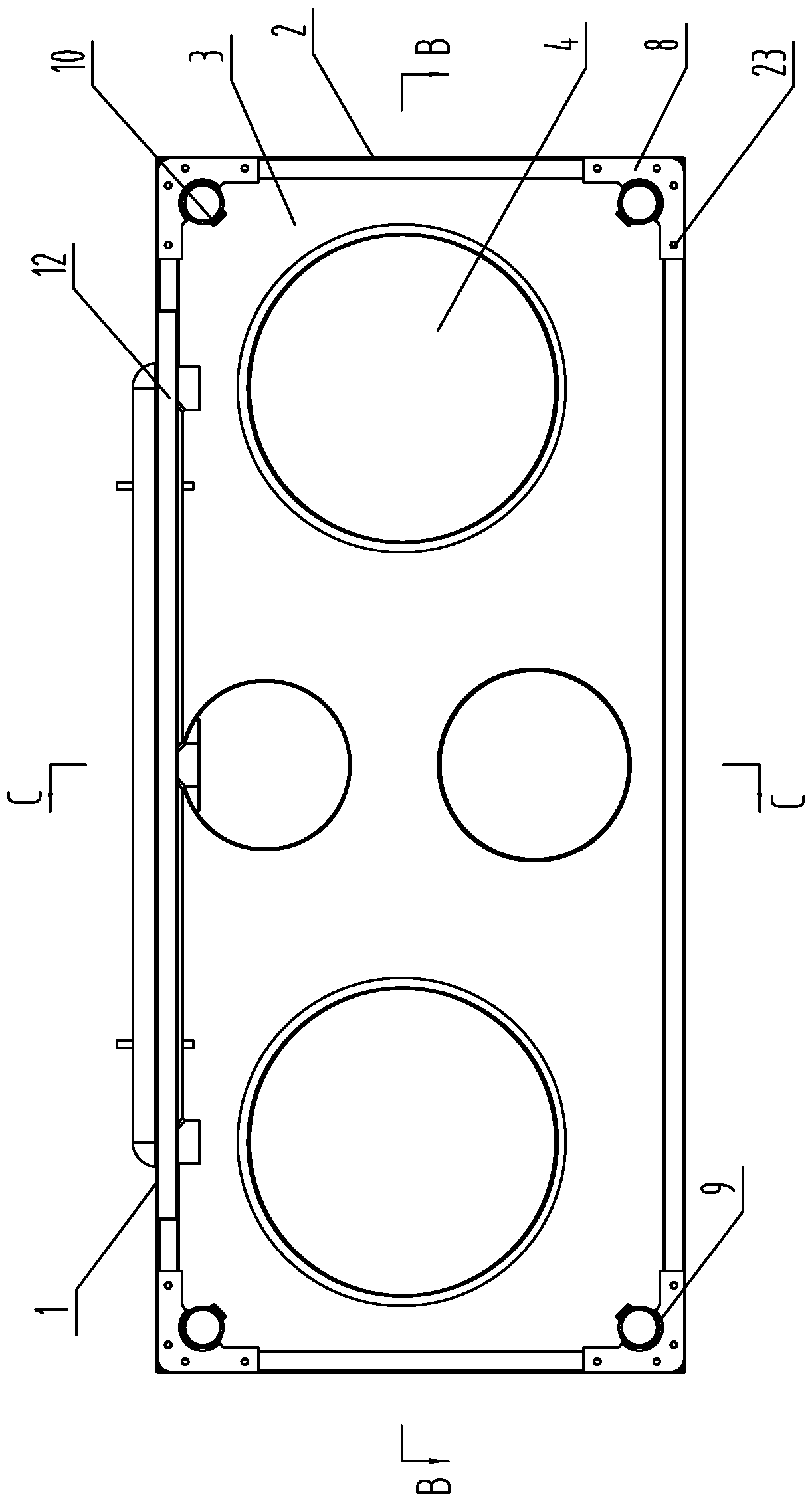

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] When the present invention is in use, the corresponding up, down, front, back, and left and right directions are defined as top, bottom, front, rear, and side in turn, and top and bottom are also called top and bottom, which will be close to the furnace body The side of the center is defined as the inner side, and the side away from the center of the furnace body is defined as the outer side accordingly.

[0042] Such as Figure 7 As shown, in the present invention, a sleeve 9 is set in the furnace leg mounting frame, and the top of the sleeve 9 is provided with a first support 11 with an "L"-shaped cross section, and more than two transverse cross-sections are provided on the side wall of the first support 11. Arranged first connecting holes 22; the sleeve 9 below the first support 11 is provided with a horizontally arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com