Photoelectric encoder coded disc, photoelectric detection device, photoelectric encoder and robot

A photoelectric encoder and photoelectric detection technology, applied in the encoder field, can solve the problems of unstable connection between the control circuit board and the light source emitting unit and the light source receiving unit, affecting the photoelectric signal transmission, etc., and achieves good photoelectric signal transmission and anti-noise performance. Good and stable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

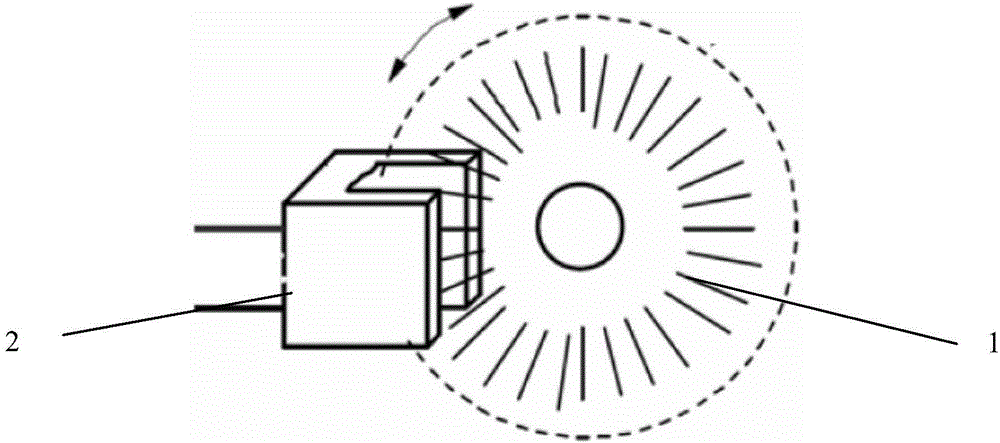

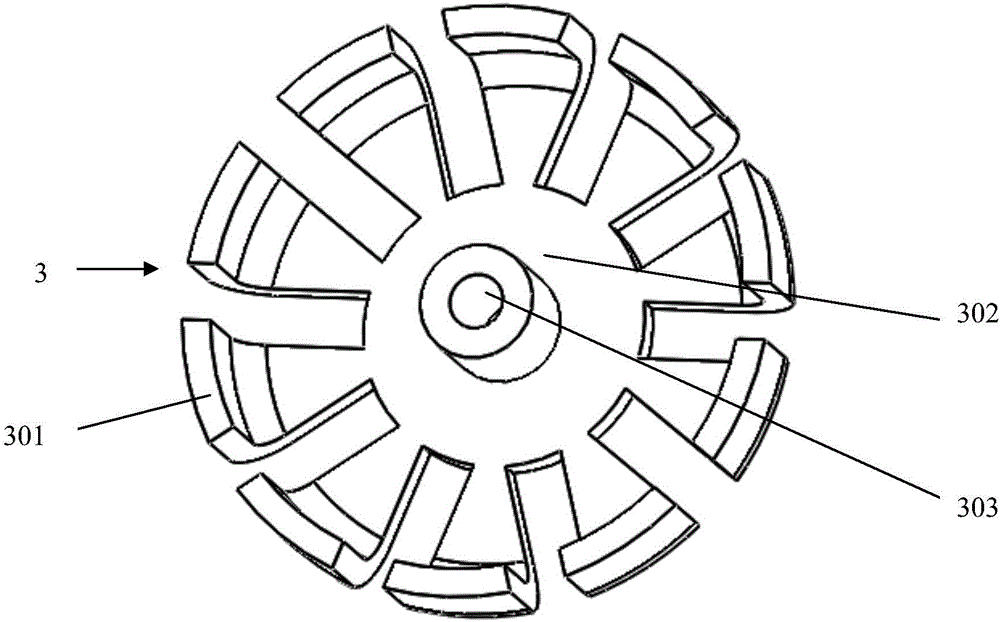

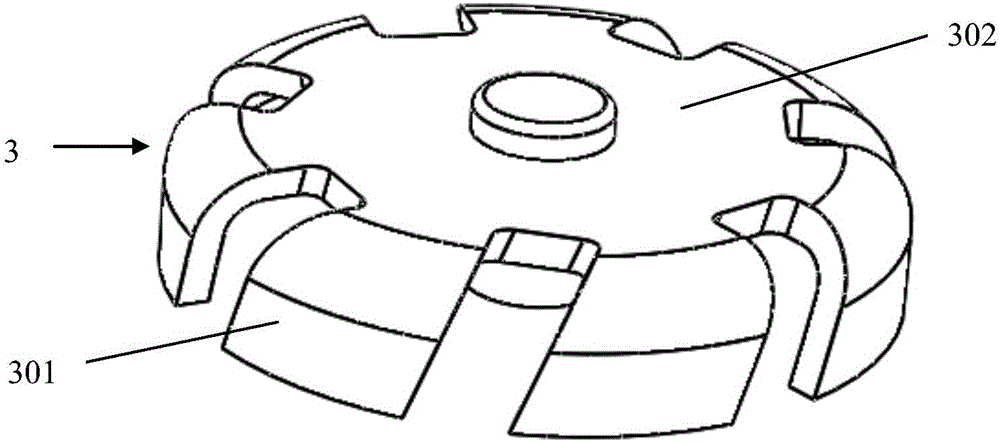

[0026] Such as figure 2 As shown, the code disc 3 of the photoelectric encoder is composed of a code reading plate 301 and a disc body 302. The disc body 302 is in the shape of a gear, and a code reading plate 301 is vertically connected to each gear tooth. The code reading plates 301 are all located on the disc body 302. On the same side, and the width extension direction of each code reading plate 301 is the same as the width extension direction of the teeth connected to the code reading plate 301, the photoelectric encoder code disc 3 is in the shape of a squirrel cage as a whole. This squirrel-cage design can effectively reduce the area of the disc body 302, and it is not necessary to place the light source emitting unit 401 and the light source receiving unit 402 on both sides of the disc bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com