Wear tester for electric power fittings

A wear test and power fitting technology, which is applied in the direction of testing wear resistance, etc., can solve the problems that the load cannot be adjusted according to the needs, the wear test results are not accurate enough, and the damage performance of the power fitting is large, so as to save the electric system and the control box. , The structure is simple and labor-saving, and the labor-saving effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

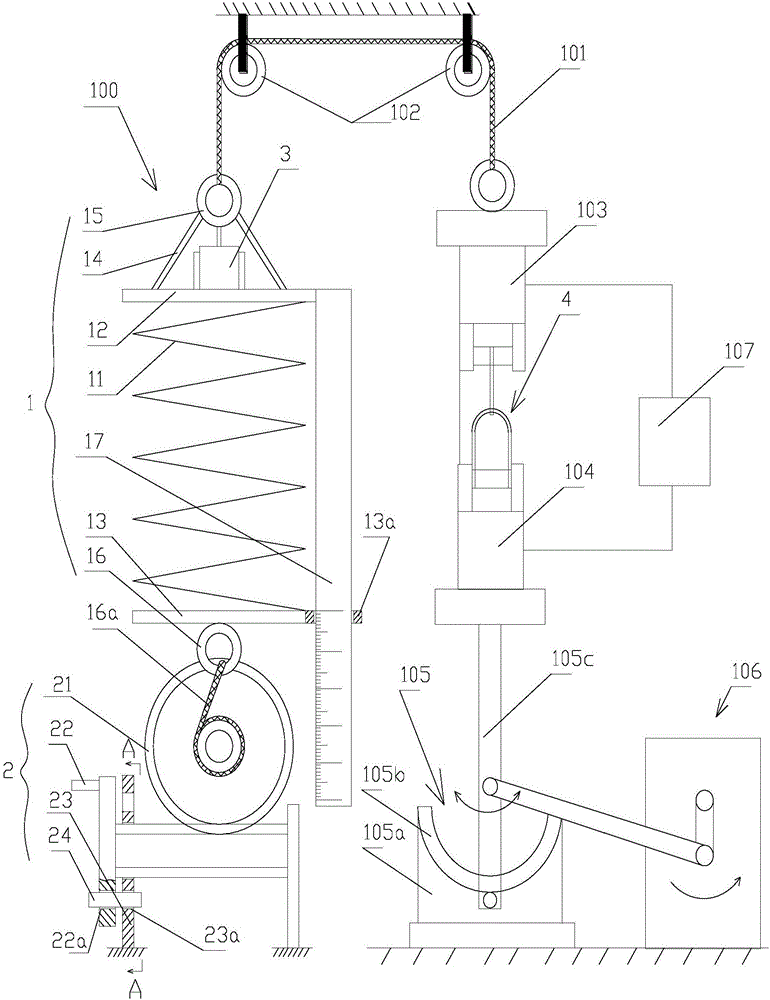

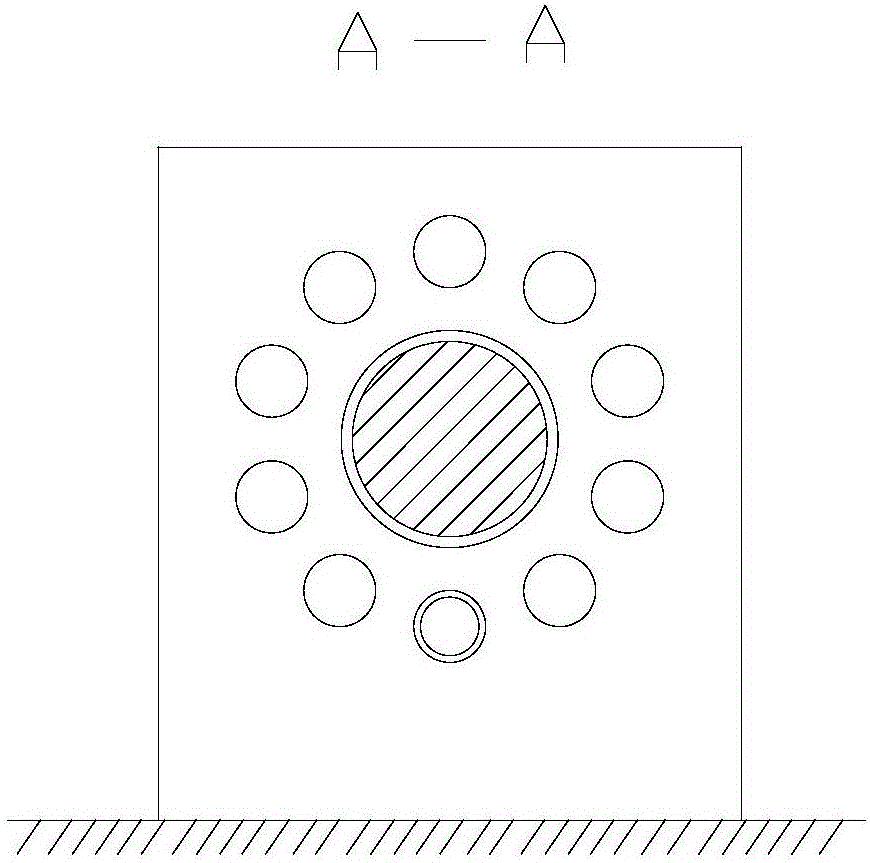

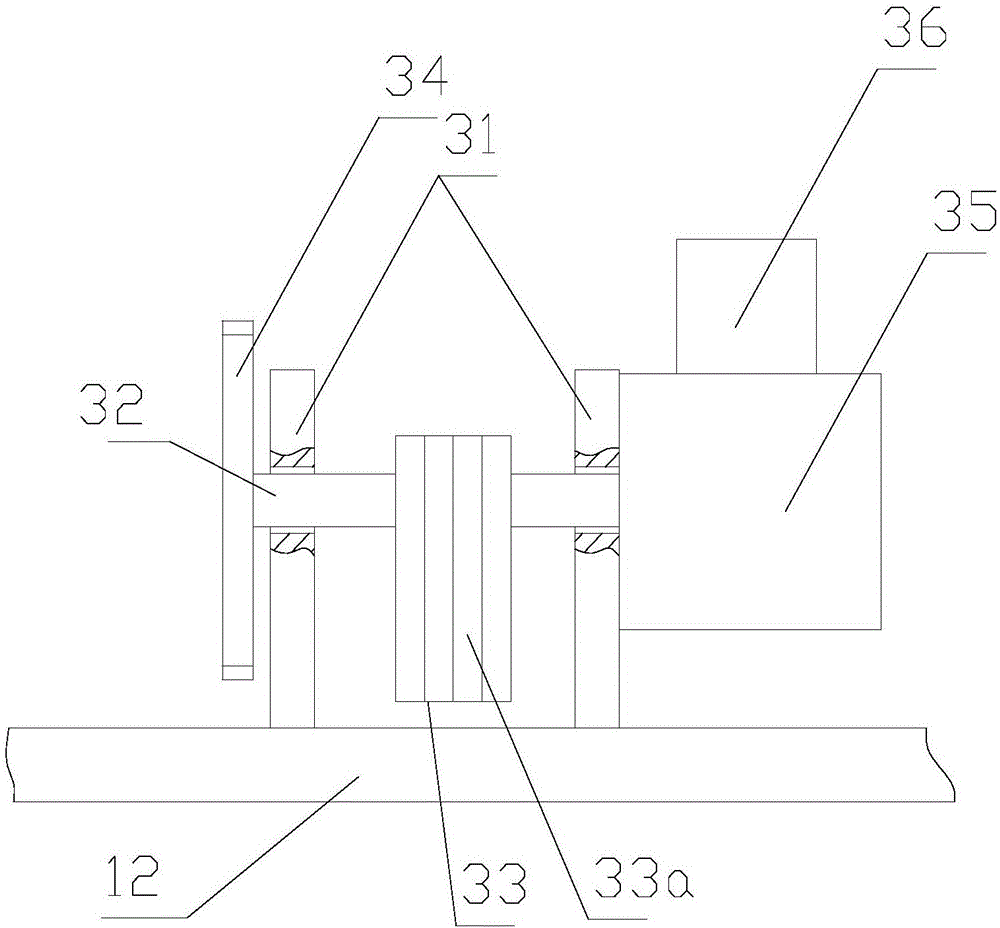

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the present invention provides a wear tester for electric power fittings, including a frame, and a load machine 100 arranged on the frame, the upper end of the load machine 100 is connected with a first suspension rope 101, and the first suspension The rope 101 is connected with the upper suspension device 103 after bypassing the pulley combination 102 hoisted on the top of the frame, and the lower suspension device 104 is arranged opposite to the upper suspension device 103. 105 includes a guide rail fixing plate 105a fixed on the bottom of the frame, an arc-shaped guide rail 105b installed on the guide rail fixing plate 105a, and a swing rod rolling sleeve 105c that can slide along the guide rail 105b. The upper part of the swing rod rolling sleeve 105c is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com