Microchromatography Downhole Bundle Tube Monitoring System

A technology of beam tube monitoring and micro-gas chromatography, which is applied in the field of micro-chromatography downhole beam tube monitoring system, can solve the problems of long gas sample analysis time and insufficient graphical network sharing support, and achieve unattended and network sharing , Overcome the effect of long transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

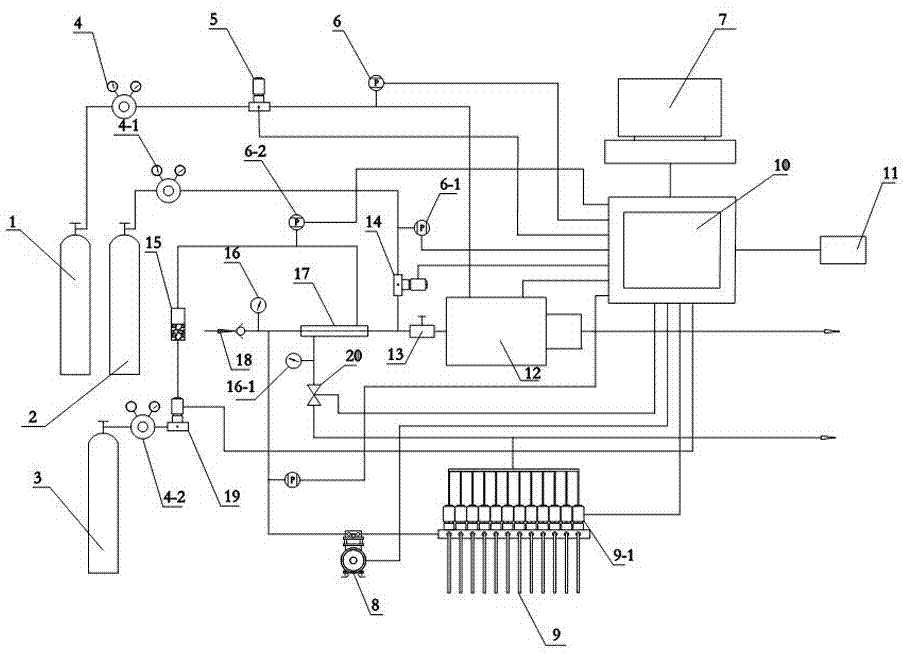

[0029] Example 1, such as figure 1 , microchromatography downhole bundle tube monitoring system, including downhole equipment and uphole equipment, the uphole equipment includes a communication control device, the downhole equipment is divided into two parts: detection analysis and bundle tube sampling, and the downhole equipment is controlled by communication with the uphole through the network The detection and analysis part includes a micro gas chromatograph, a standard gas sampling control processing device, a sample gas sampling drying control processing device, and a carrier gas supply control device. The bundle tube sampling part includes an intrinsically safe gating combination control device. device, the standard gas sampling control processing device, the sample gas sampling drying control processing device, and the carrier gas supply control device are respectively connected to the micro gas chromatograph and the communication control device, and the intrinsically sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com