Method for determining support radius and tool quantity of full face rock tunnel boring machine cutter head

A full-section, roadheader technology, used in culvert excavation tools, road and bridge fields, can solve problems such as the impact of full-section rock roadheaders on operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

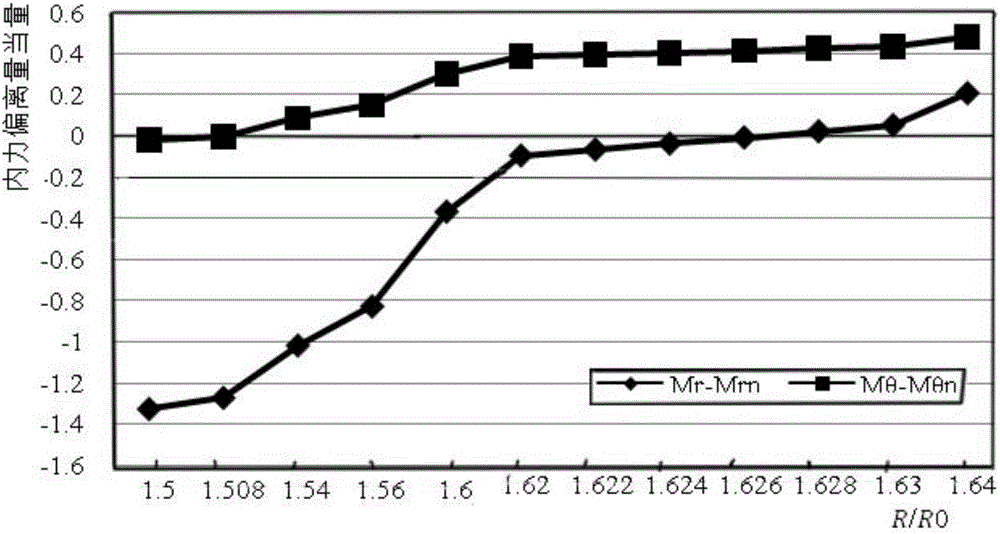

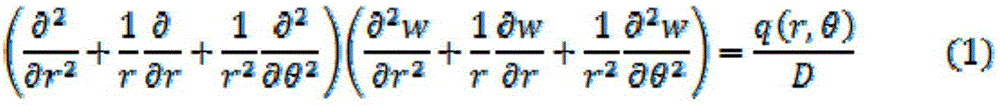

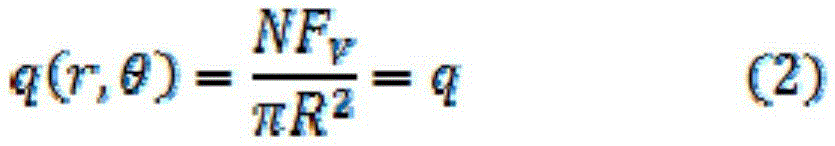

[0159] It is known that the excavation diameter of a tunnel project is 7.66m. According to the geological conditions of the surrounding rock, 56 disc-shaped hobs need to be installed on the cutter head of the full-face rock tunneling machine.

[0160] but:

[0161] According to patent requirements, 1) take R 0 =2.36(m), then:

[0162] 2) Set 28 disc-shaped hobs within the support radius of the cutter head, and 28 disc-shaped hobs outside the support radius of the cutter head.

[0163] According to the numerical simulation and test results, during the rock-breaking operation of the full-face rock boring machine, the warpage of the cutter head is reduced by nearly 25% compared with the cutter head designed by the traditional design method, and the amplitude and frequency are respectively reduced by 27% and 23%. Large bearing life increased by nearly 13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com