High pressure kettle switching device system and method

A technology of switchgear and autoclave, applied in the direction of pressure vessel/vacuum vessel, pressure vessel used in chemical process, etc., can solve problems such as failure to open, experiment failure, poor sealing of autoclave, etc., to achieve efficiency and success rate Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

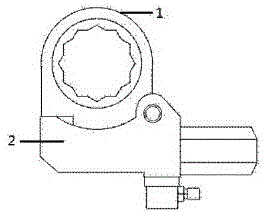

[0017] figure 1 It is a structural diagram of a hollow hydraulic wrench. As shown in the figure, the hollow hydraulic wrench includes a hollow sleeve (1) and a hydraulic wrench main body (2). The hydraulic wrench main body (2) can be connected to a manual high-pressure oil pump through a hydraulic oil pipe.

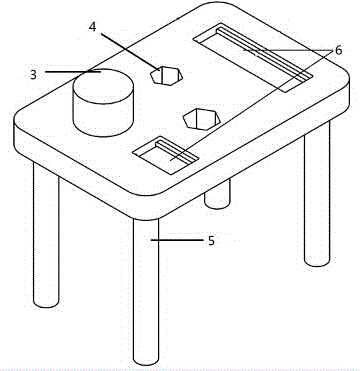

[0018] figure 2 It is a schematic diagram of a hollow hydraulic wrench working platform, including a limiting column (3), a clamping hole (4) and a supporting leg (5). The limiting column (3) is fixed on the working platform through a card slot (6), and the supporting leg ( 5) Connect with the platform through the relevant design on the bottom of the platform:

[0019] A1: Place the autoclave in the hole (4) fixed on the working platform of the hollow hydraulic wrench;

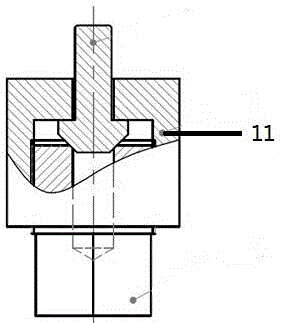

[0020] A2: Put the hollow hydraulic wrench hollow sleeve (1) into the autoclave lid (11), wherein, when opening the autoclave, the hydraulic wrench hollow sleeve (1) needs to be inserted into the lid (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com