Rotational flow negative pressure sieve

A negative pressure sieve, negative pressure technology, applied in sieves, non-rotating vibration suppression, separation of solids from solids with airflow, etc., can solve problems such as pollution, low screening efficiency, and environmental consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

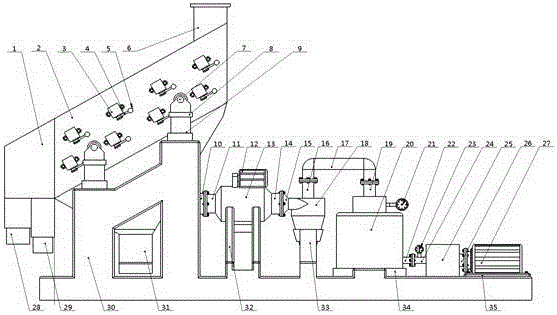

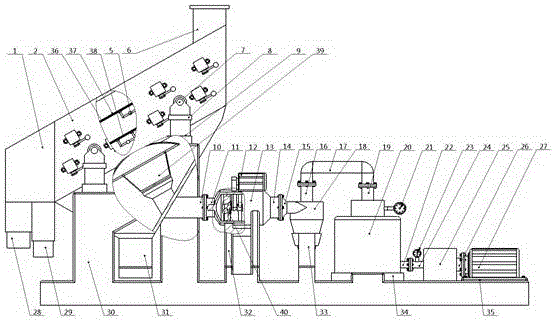

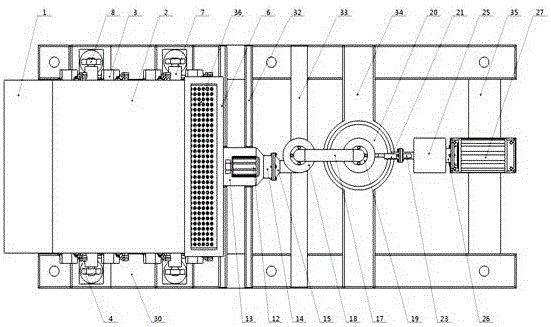

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] A cyclone negative pressure screen comprises a screening system, a vibration system, a material separation system, a cyclone negative pressure system and a support system.

[0022] The screening system is mainly composed of a screen box 2, a screen box support shaft 7, a screen fixing device 37, a screen 36, and a screen 38, wherein the screen box 2 passes through the screen box support shaft 7 on the screen box at a certain inclination angle. , The screen box support base 8 and the shock absorbing device 9 are fastened on the support system, and the surface of the screen is sprayed with wear-resistant polyurethane material to enhance the compression and wear resistance of the screen, reduce the replacement frequency of the screen, and the screen fixing device 37 is installed on both sides of the inside of the screen box 2, and the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com