Wheel frame reinforcing structure production system

A technology for reinforcing structure and manufacturing system, which is applied in the field of manufacturing system of wheel frame reinforcing structure, can solve the problems of poor mechanical properties, structural strength or toughness, limited manufacturing method, time-consuming and labor-consuming, etc., and achieves wide application and manufacturing method. various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are only used to illustrate the possible implementation aspects of the present invention, but they are not intended to limit the scope of protection of the present invention, and are described first.

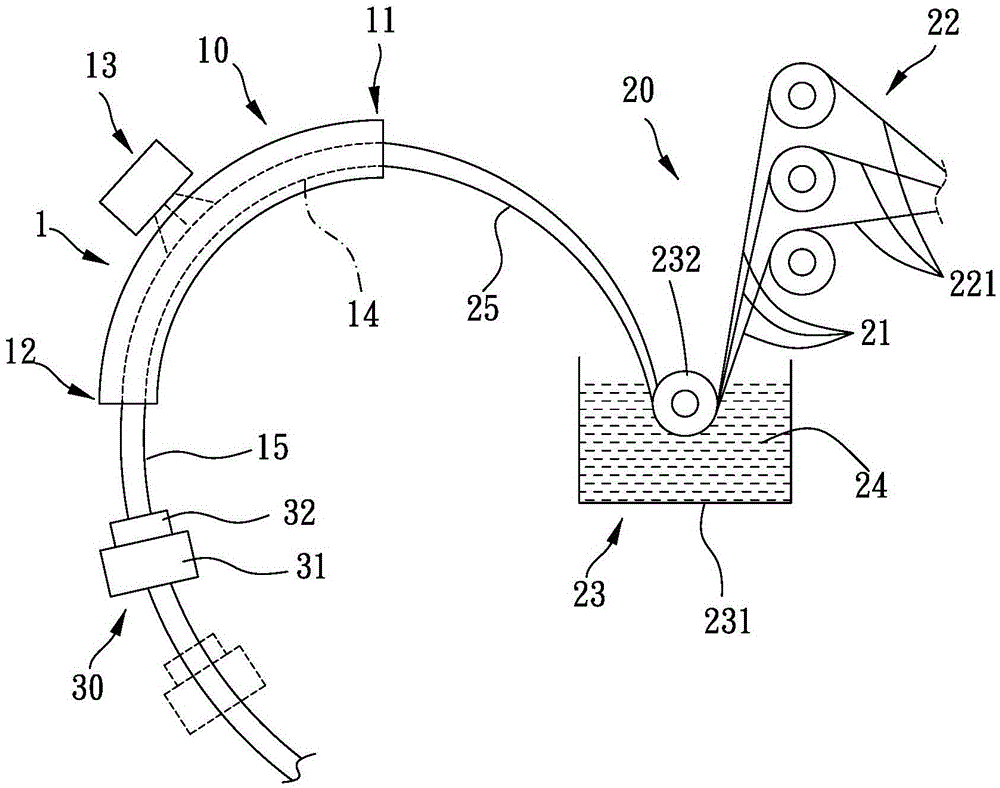

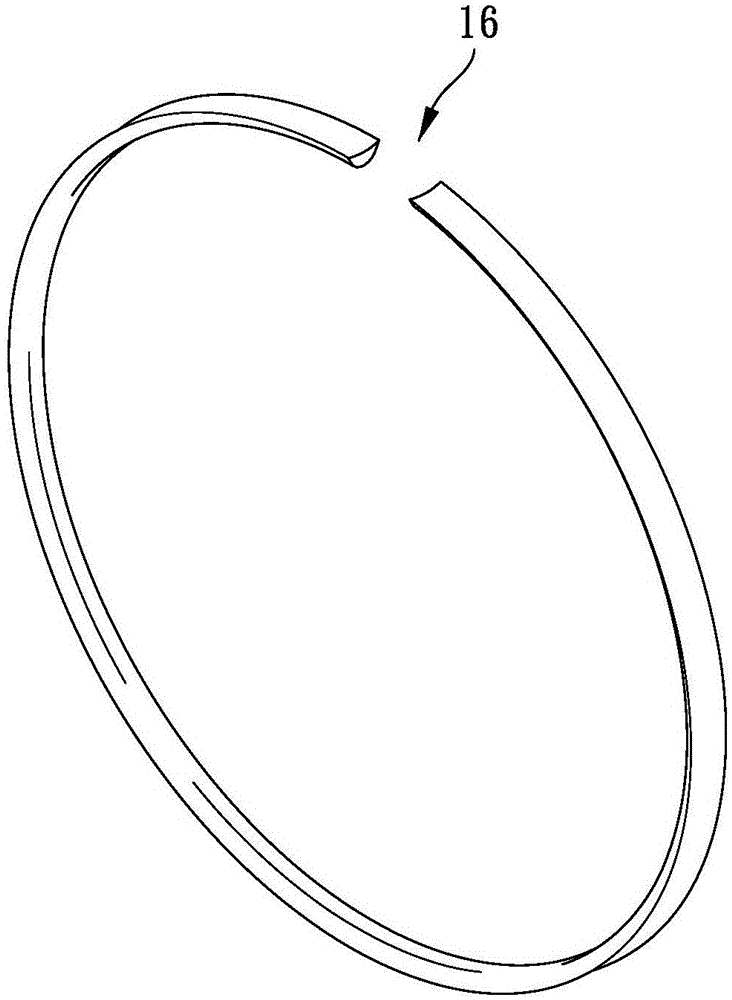

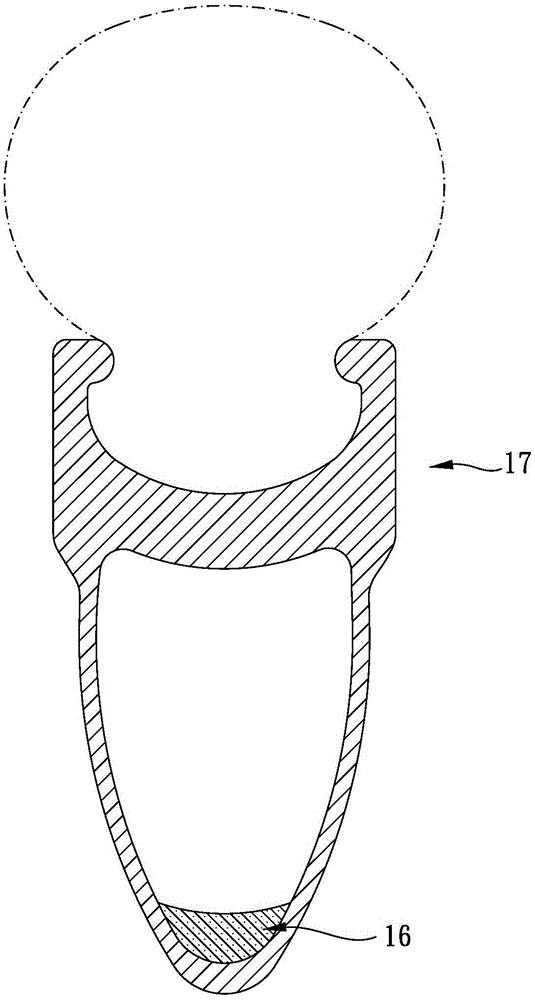

[0024] Please refer to Figure 1 to Figure 3 , Which shows a first preferred embodiment of the present invention, a manufacturing system 1 of a wheel frame reinforcement structure of the present invention includes a molding device 10, a wire supply device 20, and a moving mechanism 30.

[0025] The molding device 10 may have an input end 11, an output end 12, and a hardening mechanism 13, and the hardening mechanism 13 is arranged between the input end 11 and the output end 12, and between the input end 11 and the output end 12 A channel 14 is communicated with, and the hardening mechanism 13 is adjacent to the channel 14. For example, the molding device 10 may include a mold device, for example, the input end 11 and the output end 12 are provided at two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com