Supporting device and portable ultrasonic impact gun provided with same

A technology of ultrasonic impact gun and support device, which is applied in the field of support device and portable ultrasonic impact gun, which can solve the problems of inability to meet large batch processing, high technical requirements of workers, and high maintenance costs, so as to reduce the dependence on the technical level of workers and improve efficiency And product yield, easy maintenance and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

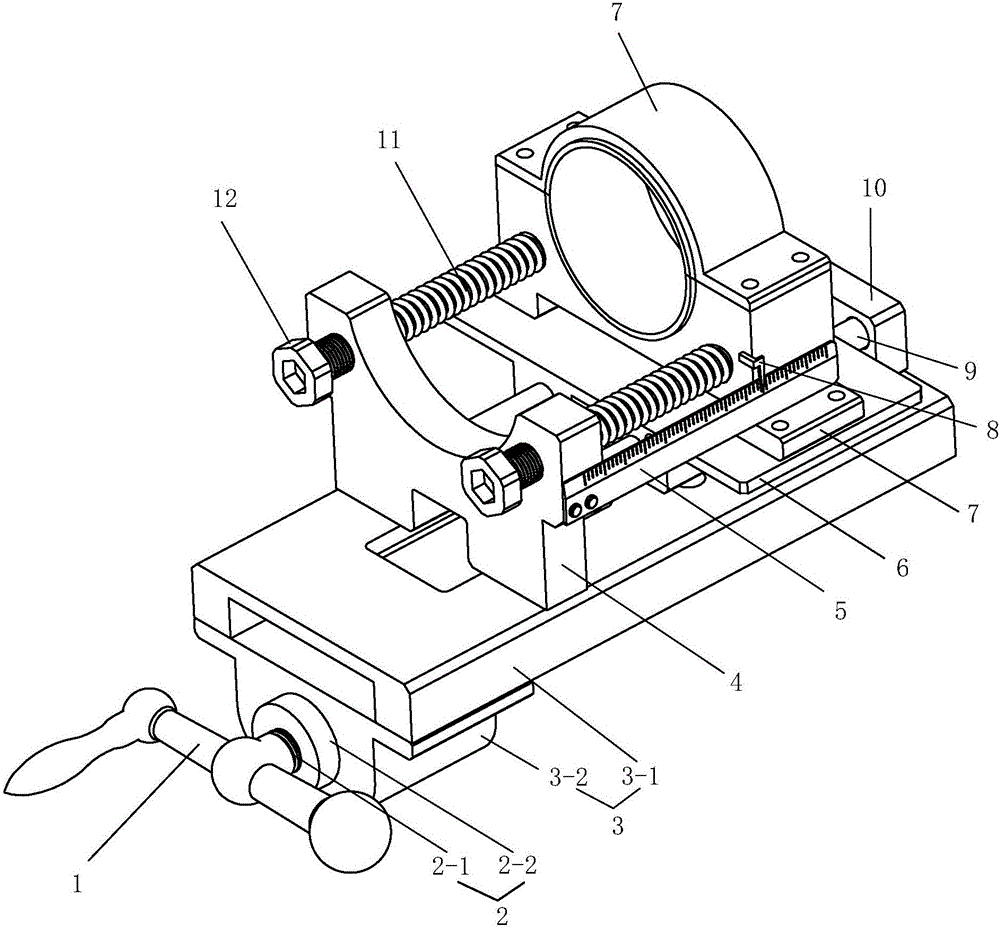

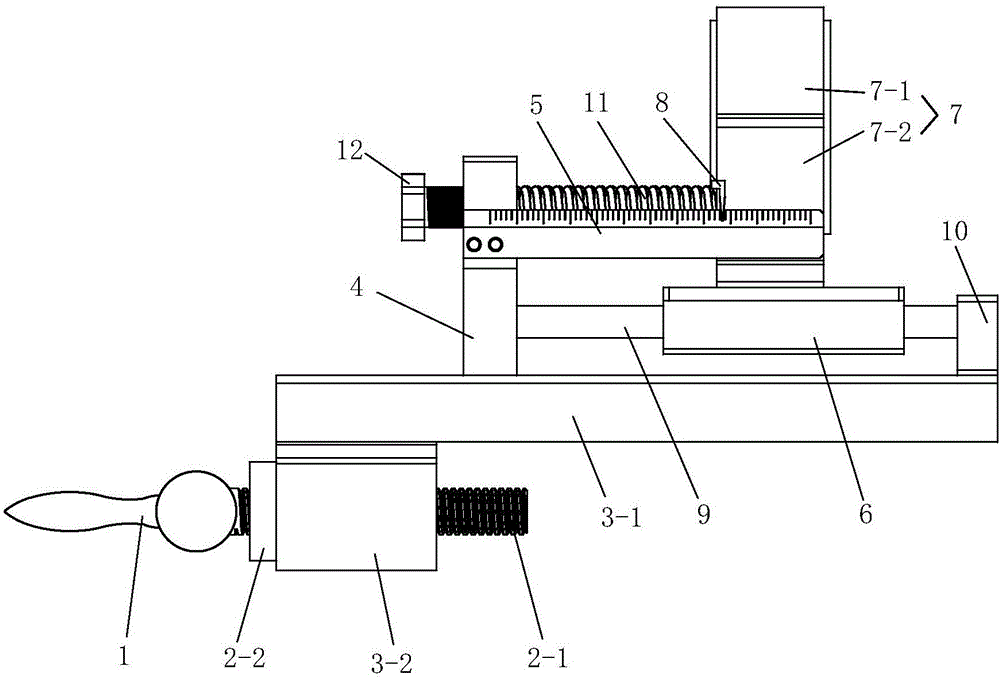

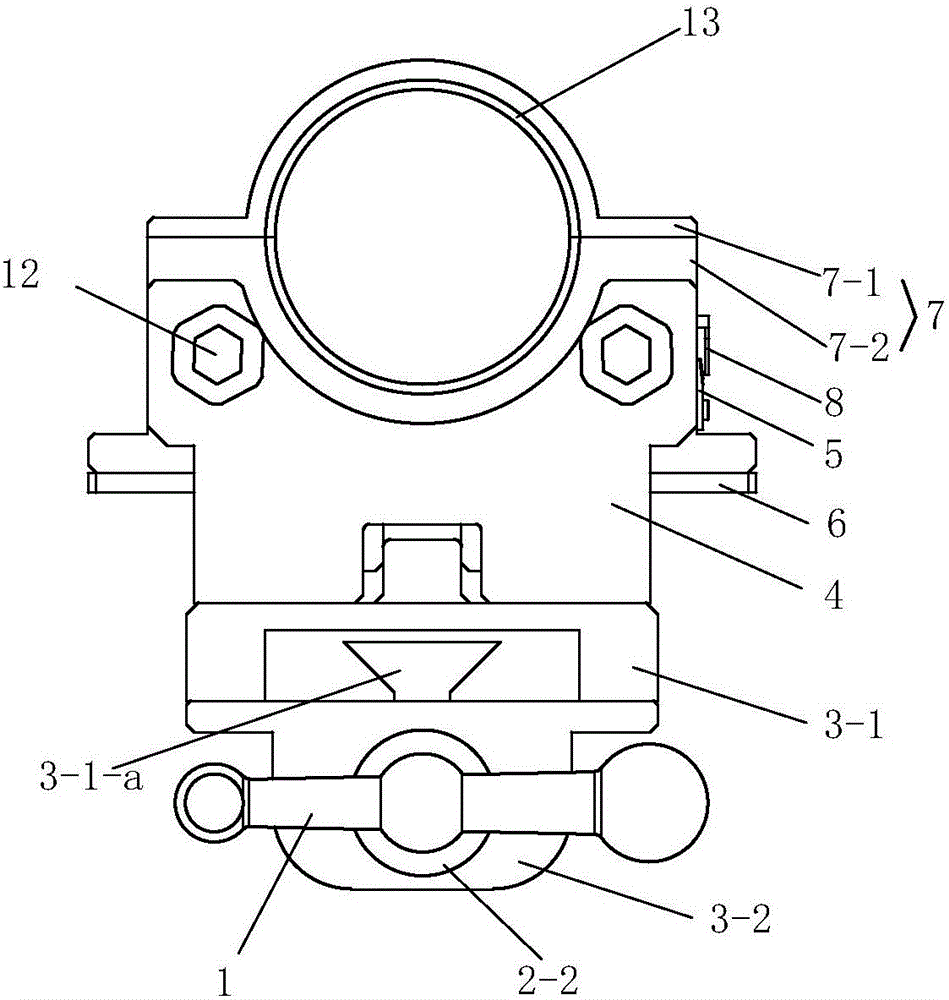

[0030] See Figure 1 to Figure 13 , The support device has a ball screw mechanism 2, a sliding seat 3, a guide rod front frame 4, two guide rods 6, a support base 7 and a guide rod rear frame 10.

[0031] The ball screw mechanism 2 includes a ball screw 2-1 whose axial movement is hindered and a nut 2-2 threaded on the ball screw 2-1, and an operating handle 1 is connected to the front end of the screw 2-1. Described sliding seat 3 is made up of main body 3-1 and the nut seat 3-2 that is connected on the bottom front side of main body 3-1 with screw. The rear side of the bottom surface of the main body 3-1 is provided with a dovetail groove 3-1-a. The nut seat 3-2 is provided with a forward and backward through hole 3-2-a, and the nut seat 3-2 is sleeved on the nut 2-2 through the through hole 3-2-a, and tightly fits with the nut 2-2. When the ball screw 2-1 rotates, the nut 2-2 drives the sliding seat 3 to move on the ball screw 2-1 through the nut seat 3-2, and the sliding...

Embodiment 2

[0039] The support device adopts the anti-vibration rubber pad 13 on the inner wall of the lower seat 7-2 of the support seat 7 and the upper cover 7-1. All the other are identical with embodiment 1. The gun body of the portable ultrasonic impact gun is placed in the positioning hole 7-a of the support seat 7 of the supporting device, and the gun body is wrapped by the anti-vibration rubber pad on the positioning hole, so no rubber ring is needed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com