Gas injector with improved sealing

A technology of gas injectors and sealing components, applied in fuel injection devices, special fuel injection devices, combustion engines, etc., to achieve the effect of simple cost, good sealing and improved sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

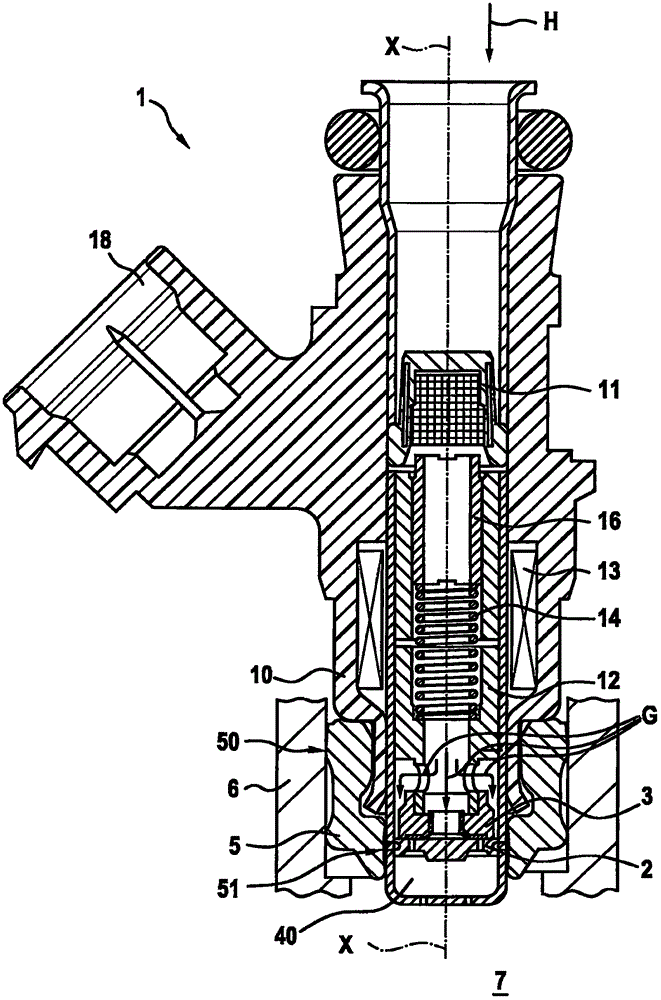

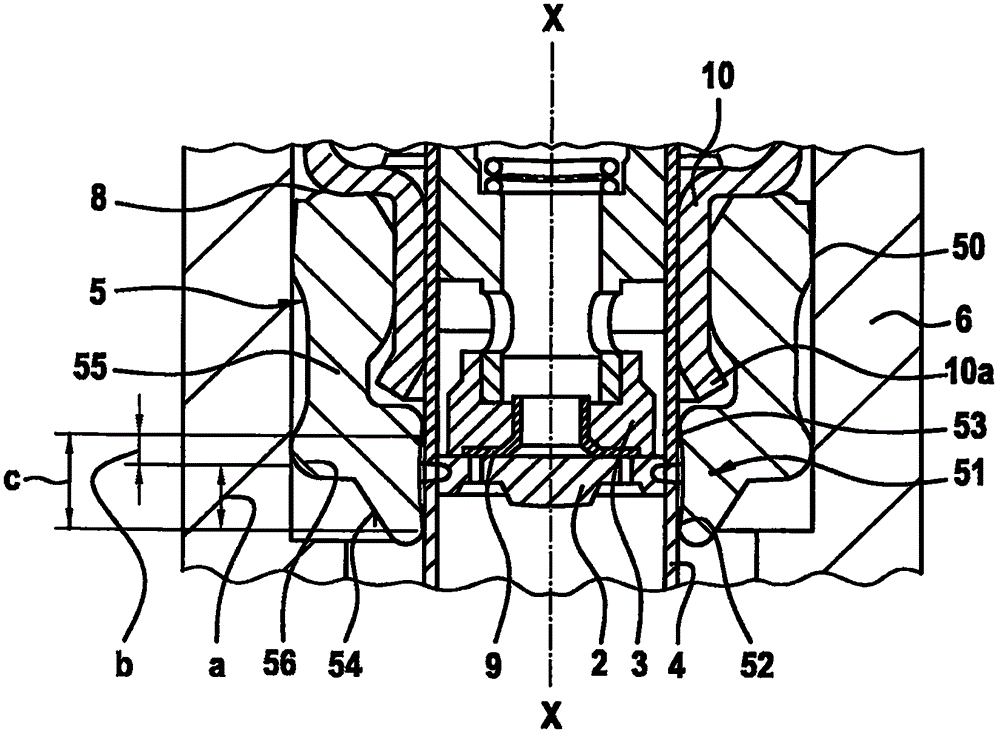

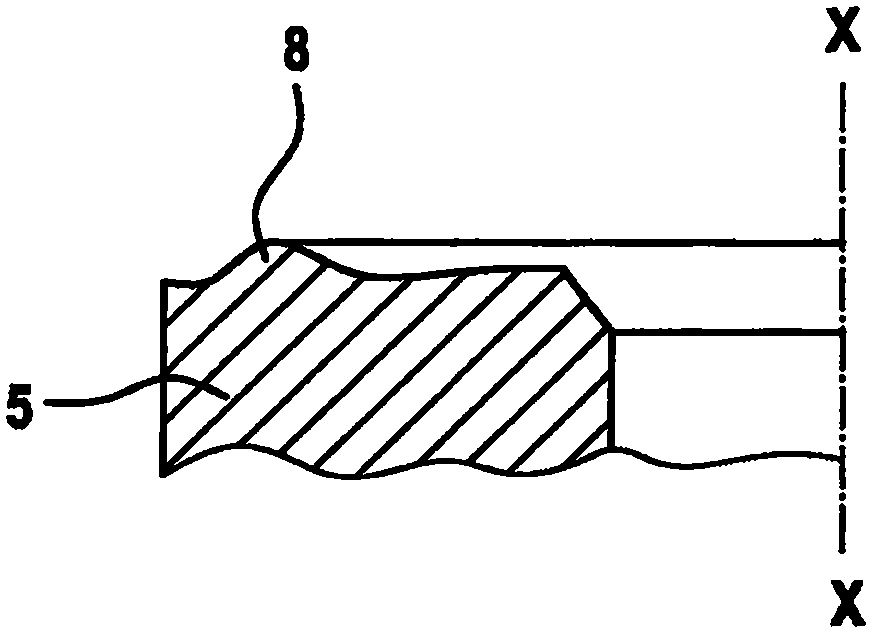

[0019] Refer to the attached Figures 1 to 3 The gas injector 1 according to a preferred embodiment of the present invention will be described in detail.

[0020] The gas injector 1 of this embodiment is arranged on the intake pipe 7 and is used to blow gaseous fuel into said intake pipe. Alternatively, the gas injector can also blow directly into the combustion chamber.

[0021] The gas injector 1 comprises a valve housing 10 , a solenoid armature 12 , a solenoid coil 13 and a closing spring 14 . An adjustment pin 16 is provided to adjust the return force of the closing spring 14 . Gas is supplied along the axis X-X of the gas injector (arrow H) and is guided through the filter 11 . The solenoid coil 13 is fixed on the valve housing 10 . The electrical plug connector 18 is arranged laterally on the gas injector.

[0022] Fastened to one axial end of the magnetic armature 12 is a closing element 3 on which an elastomeric sealing element 9 is arranged. The closing element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com