A bed material external circulation device and operation method for circulating fluidized bed boiler

A circulating fluidized bed and external circulation technology, applied in the field of low-ash low-quality fuel combustion equipment, can solve problems affecting the normal and stable operation of boilers, achieve the effects of reducing slag discharge losses, achieving self-sufficiency, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

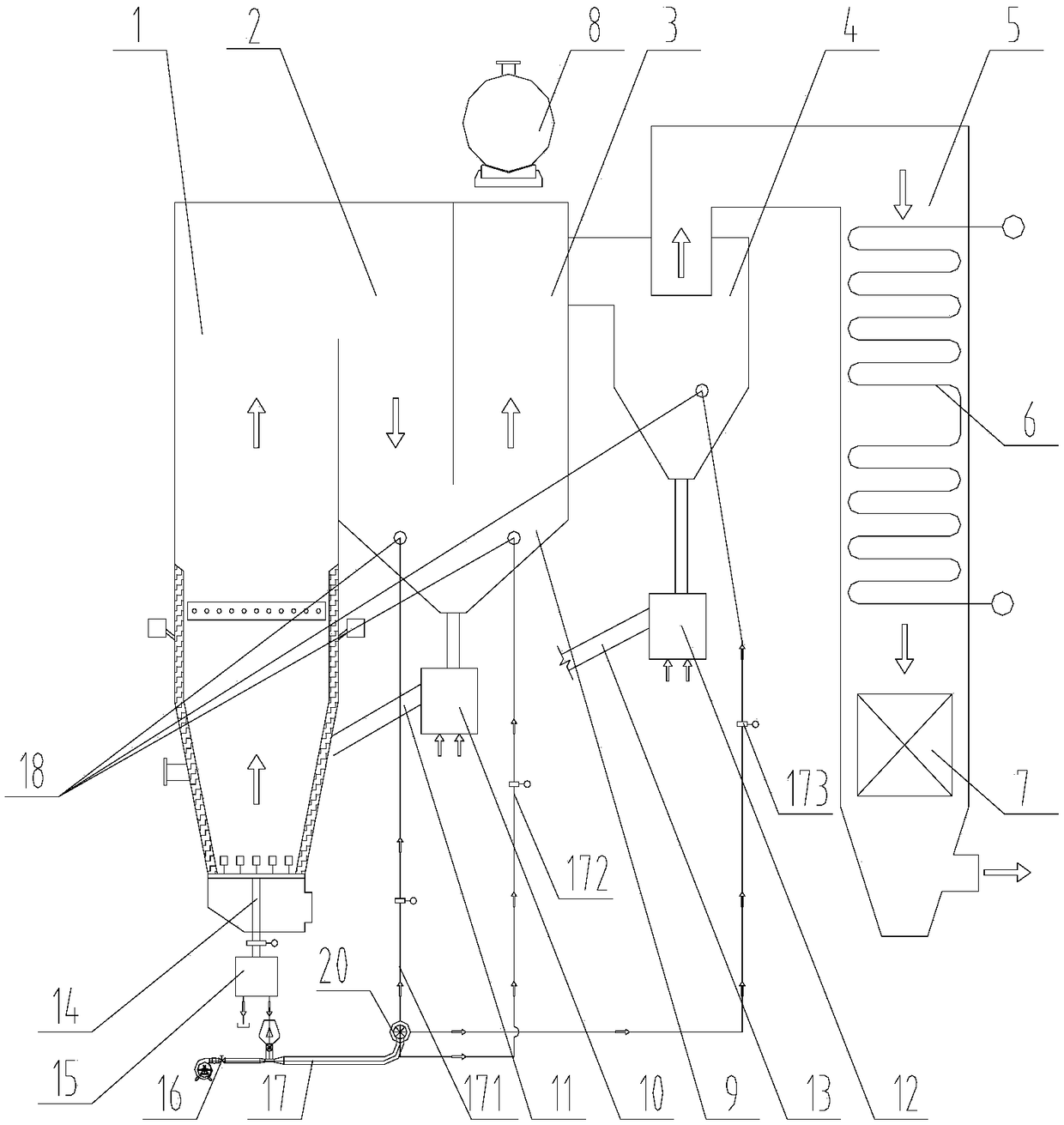

[0051] The invention provides a multi-process circulating fluidized bed boiler, which is equipped with an external circulation device for bed materials, and has a structure such as figure 1 shown, including:

[0052] Main combustion chamber 1, auxiliary combustion chamber 2, burnout chamber 3, separator 4, tail shaft 5, economizer 6, air preheater 7, drum 8, ash hopper 9, primary return box 10, primary Return pipe 11, secondary return box 12, secondary return pipe 13, slag discharge pipe 14, screening device 15, bed material return device 16, return pipeline system 17, nozzle 18, hose 19 and multi-directional Valve 20.

[0053] The main combustion chamber 1, the secondary combustion chamber 2 and the burnout chamber 3 are arranged side by side in sequence, the separator 4 is arranged behind the flue gas outlet of the burnout chamber 3, and the outlet flue of the separator 4 is connected with the flue of the tail shaft 5, An economizer 6 and an air preheater 7 are arranged in...

Embodiment 2

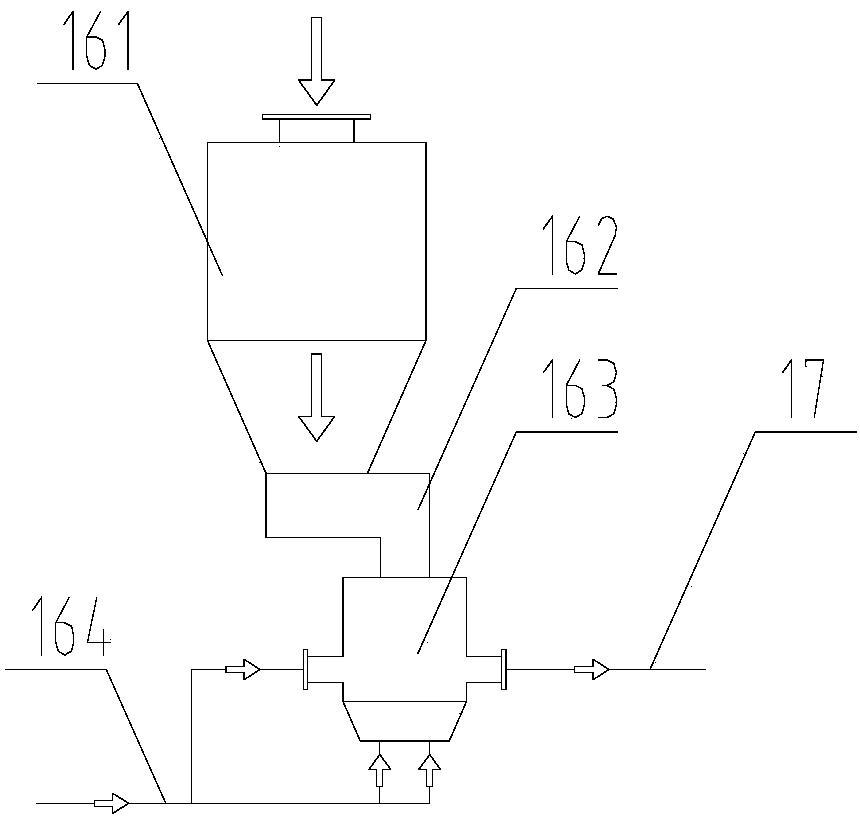

[0074] The present invention also provides a bed material external circulation device for a circulating fluidized bed boiler, the bed material external circulation device includes:

[0075] Screening device 15, bed material return device 16, return pipeline system 17, nozzle 18 and multi-way valve 20;

[0076] The screening device 15 is arranged at the bottom of the slag discharge pipe 14, and the material outlet of the screening device 15 is connected with the bed material returning device 16;

[0077] A multi-way valve 20 is arranged between the bed material return device 16 and the return pipeline system 17, and the different outlets of the multi-way valve are connected to the corresponding delivery pipelines of the return pipeline system 17;

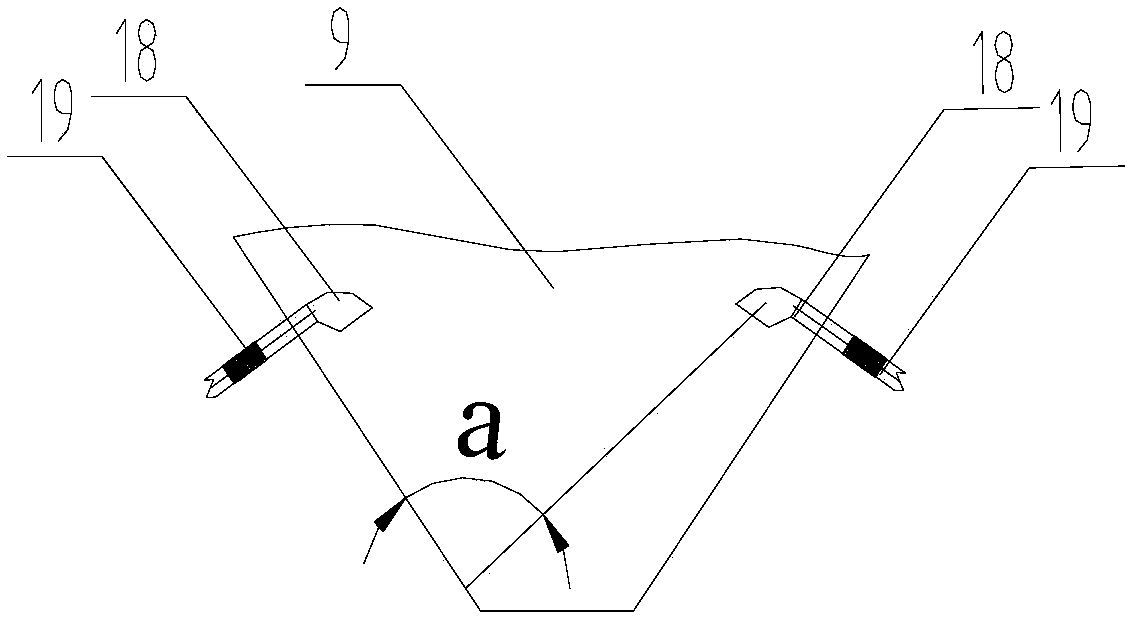

[0078] The return pipeline system 17 returns the bed material to the nozzle 18 of the ash hopper 9 installed in the corresponding equipment through the corresponding delivery pipeline, and sprays it onto the inner wall of the ash hop...

Embodiment 3

[0081] The present invention also provides a bed material external circulation operation method for circulating fluidized bed boiler, which includes the following internal circulation of ash and the external circulation operation method of bed material:

[0082] Wherein the internal circulation operation method of ash comprises the following steps:

[0083] Step S101, when the ash volume of the primary return box 10 is relatively large at the initial stage of boiler operation: increase the air distribution of the primary return box 10 to increase the amount of primary return material;

[0084] Step S102, after the boiler has been running for a period of time, the temperature in the dense-phase area gradually increases, and at this time, gradually increase the air distribution of the secondary return material box 13 to increase the amount of secondary return material;

[0085]In step S103, when the boiler is running at full load, the air distribution of the first-level return b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap