Grille screen and method for detecting bricklaying mortar plumpness through grille screen

A technology of mortar fullness and 100 grids is applied in the field of inspection and detection of construction projects, which can solve the problems of no open structure, too much energy, and long time consumption of 100 grids, so as to reduce the steps of cleaning 100 grids, The effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

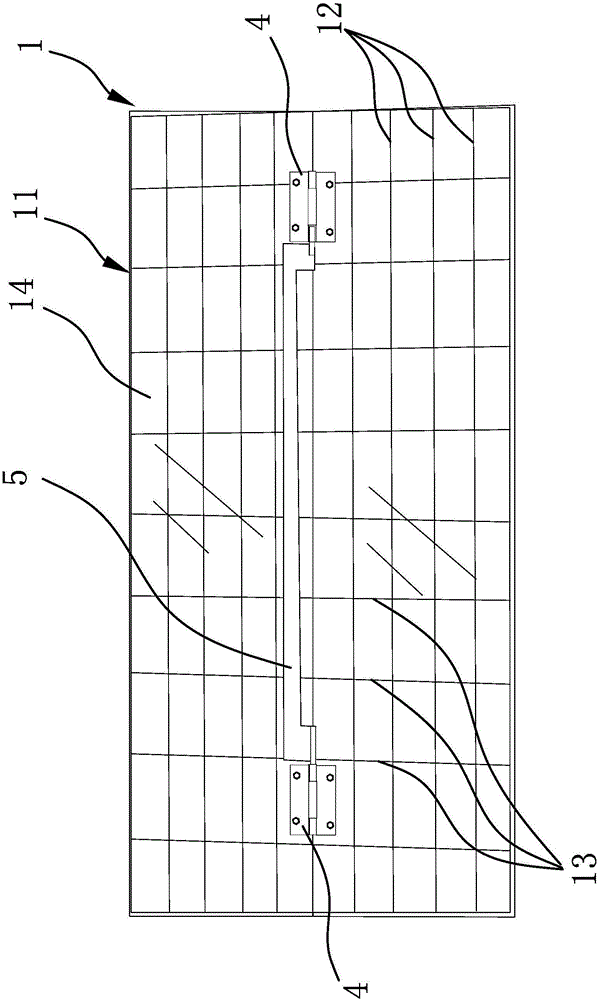

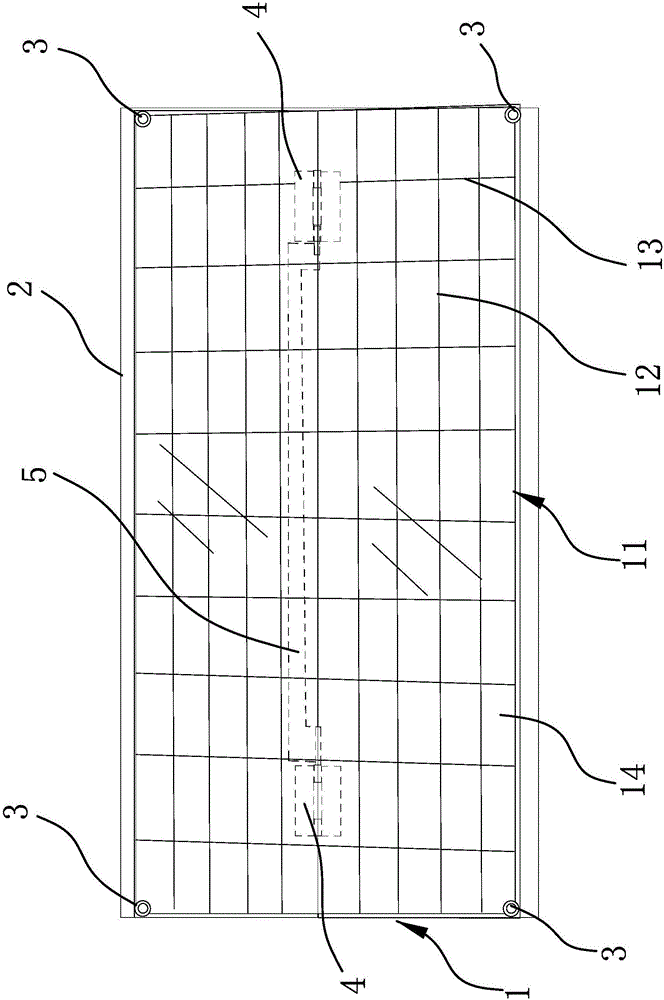

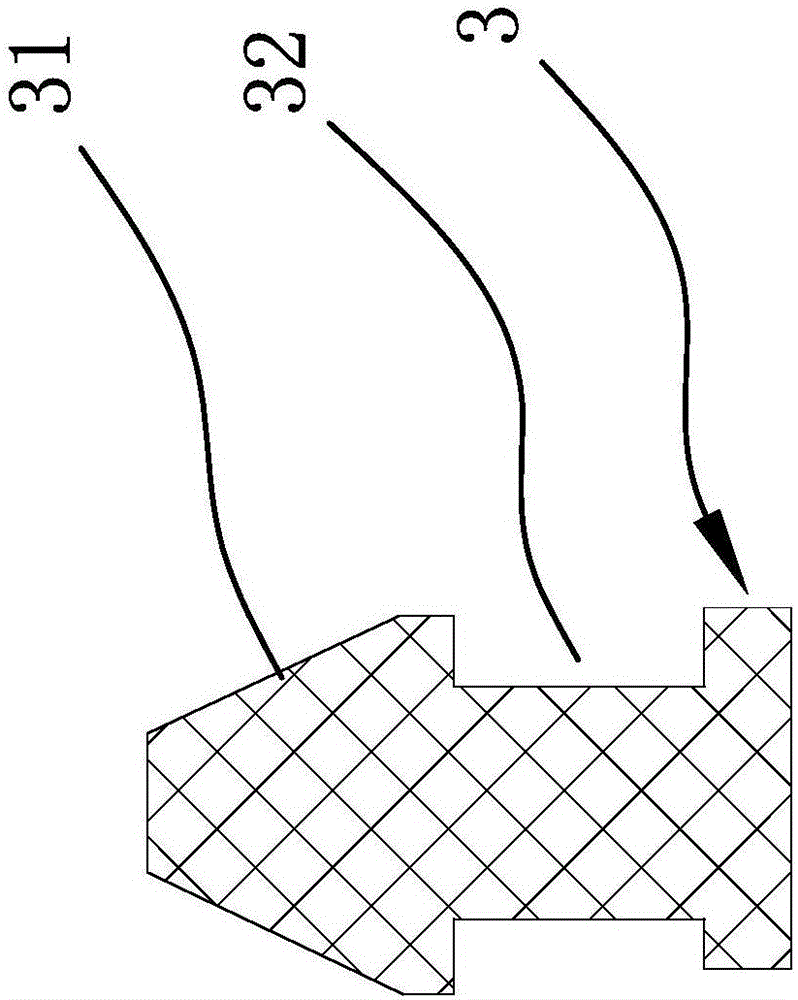

[0032] Such as figure 1 and figure 2 As shown, this grid comprises transparent film 2 and grid frame 1 in the shape of a rectangular plate, and one side of grid frame 1 has several grids 14 that are adjacently arranged and evenly distributed, and all grids 14 are equal in size, and grid frame 1 The connecting column 3 is fixed on the top, the transparent film 2 is rectangular and the length of the transparent film 2 is not less than the length of the network frame 1, and the width of the transparent film 2 is not less than the width of the network frame 1; the transparent film 2 can be connected to the connecting column 3 And laid on the side of the network frame 1 with the grid 14; the plastic board 11 has two pieces and the two plastic boards 11 are connected by the hinge 4, and the joint of the two plastic boards 11 is also provided with a handle 5. The size of the grid frame 1 in the present embodiment matches the size of the brickwork. During use, at first the disposabl...

Embodiment 2

[0037] This embodiment is a method for detecting the plumpness of bricklaying mortar using the hundred-grid grid in Embodiment 1. The above-mentioned hundred-grid grid includes a grid frame 1 in the shape of a rectangular plate, and one side of the grid frame 1 has several grids 14. 1 is fixed with four connecting columns 3, and this method specifically includes the following steps:

[0038] a. Preparing to lay bricks: remove the bricks in the wall, randomly select three bricks, and place the bottom of the three bricks upwards;

[0039] b. Install the transparent film 2: take a piece of disposable transparent film 2, lay the transparent film 2 on the grid 1 side with the grid 14, and connect the transparent film 2 to the connecting column 3;

[0040] c. Detection: place the network frame 1 on one of the bricks, and align the edge of the network frame 1 with the edge of the bricks, and the transparent film 2 faces the bricks and attaches to the bottom surface of the bricks. gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com