Rotary cultivator cutter shaft size multi-criterion design optimization method

An optimization method and technology of rotary tiller, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of complex operation, conservative results, inability to effectively take into account the strength of the cutter shaft and the cost criteria of manufacturing economy, and achieve the design idea simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A multi-criteria design optimization method for the cutter shaft size of a rotary tiller, the optimization method includes the following steps:

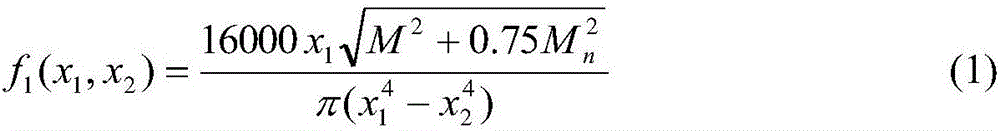

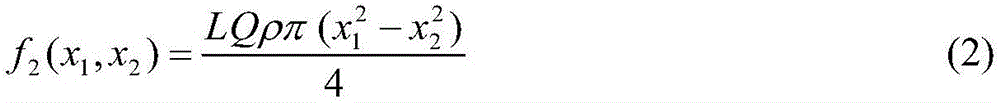

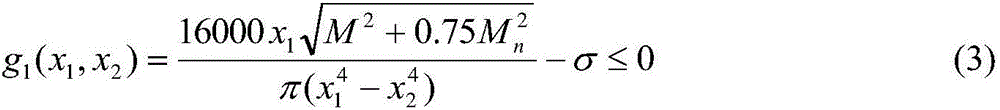

[0033] 1) Establish the stress function and cost function of the rotary cultivator knife bearing, see formulas (1) and (2) respectively:

[0034] f 1 ( x 1 , x 2 ) = 16000 x 1 M 2 + 0.75 M n 2 π ( x 1 4 - x 2 4 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com