Wire locking terminal with torsional spring

A wire-lock terminal and torsion spring technology, applied in the field of wire-lock terminals, can solve problems such as installation troubles, time-consuming, and laborious problems, and achieve the effects of flexible and convenient layout, quick and convenient use, and low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

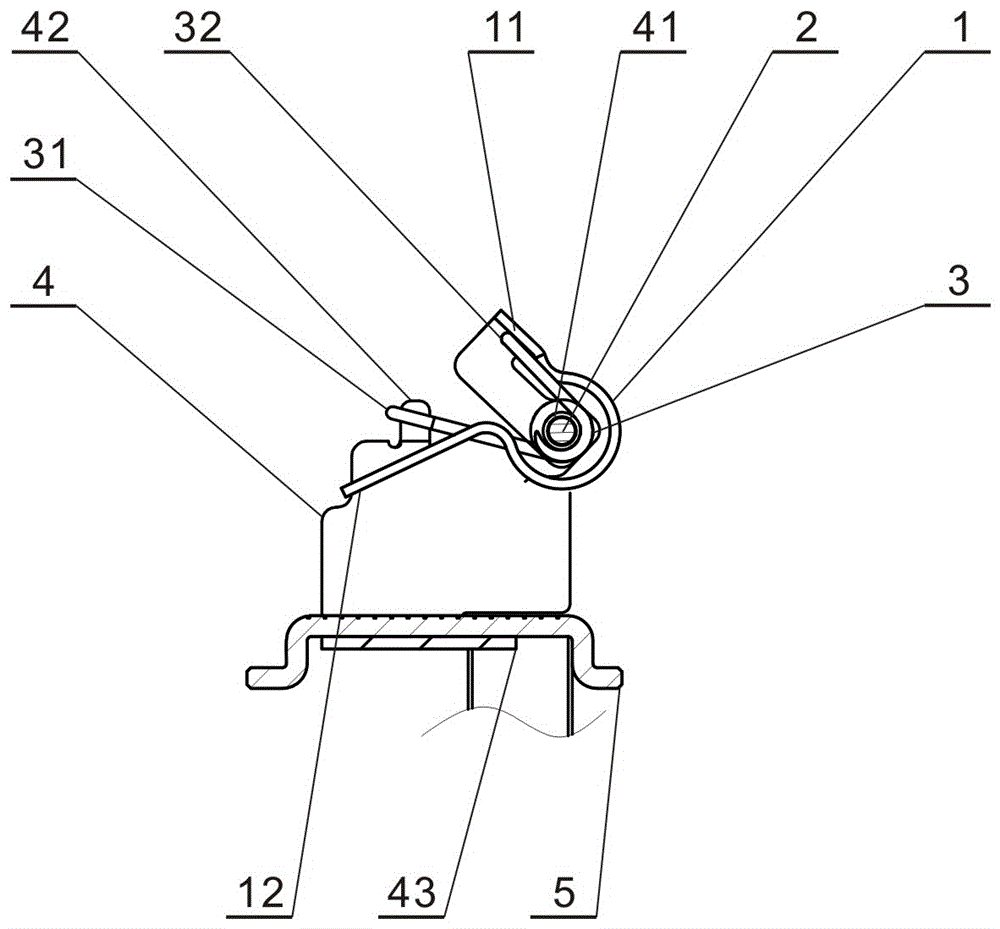

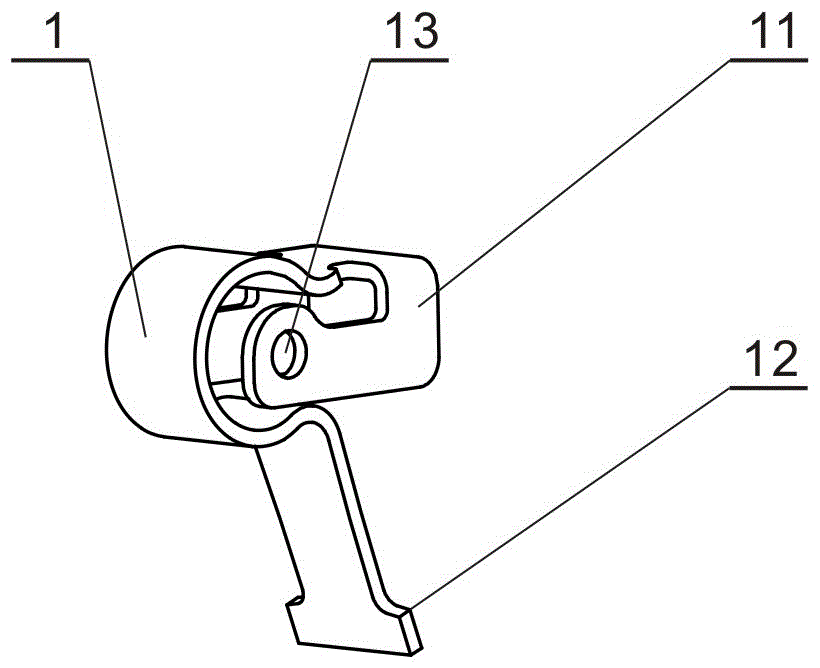

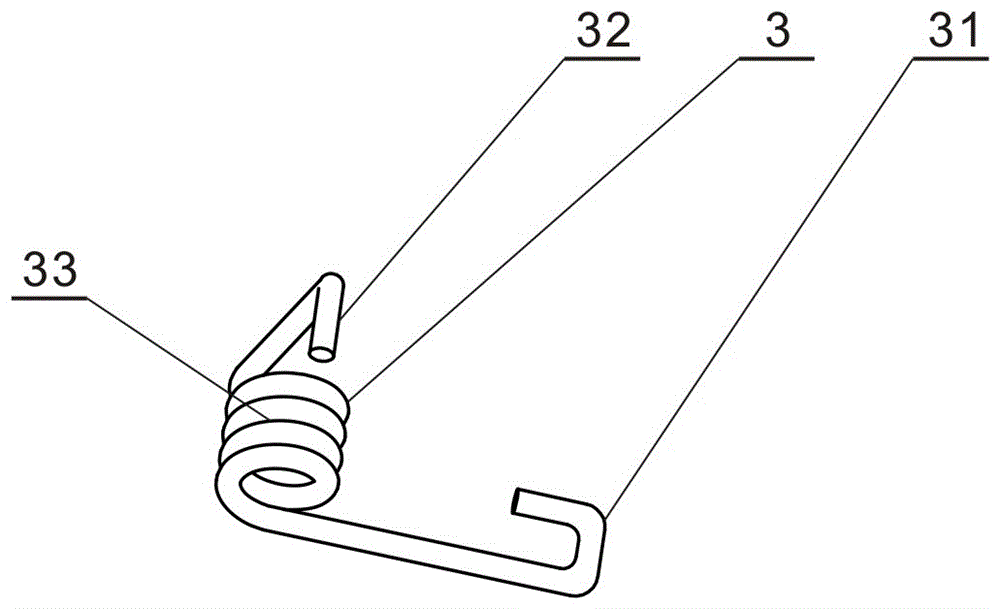

[0026] refer to figure 1 , Figure 5 , The present invention is used in conjunction with the switch cabinet. There are several locking wire terminal blocks inside the switch cabinet, and the corresponding locking wire terminal blocks are provided with safety buttons 6 . When in use, the present invention is inserted into the corresponding locking wire terminal base as required, and when the wire to be connected is plugged into the present invention, the purpose of quick wire locking can be realized.

[0027] Below in conjunction with the embodiment of the present invention and accompanying drawing, the working process of the present invention is further described as follows:

[0028] Wire from insertion to locking process

[0029] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 According to the design requirements of the switch cabinet, the present invention is installed in the corresponding lock wire terminal block of the switch cabinet, and the wire s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com