Semi-automatic feeding machine for sheep farm

A semi-automatic, feeding machine technology, applied in the direction of animal feeding device, application, animal husbandry, etc., to achieve the effect of stable operation, reliable structure and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

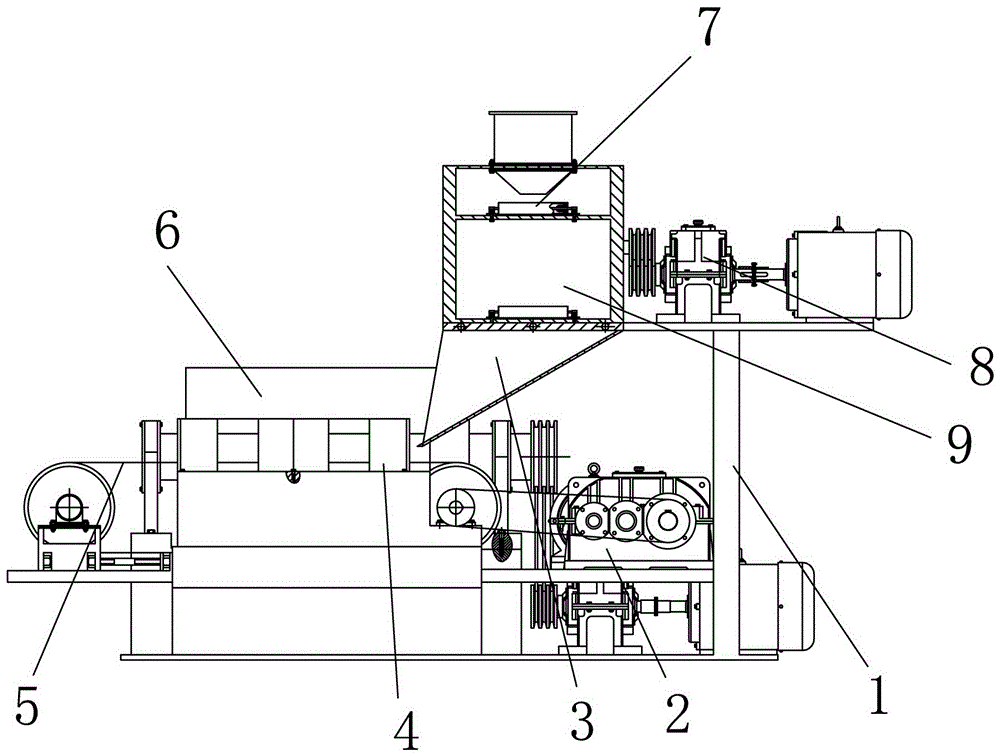

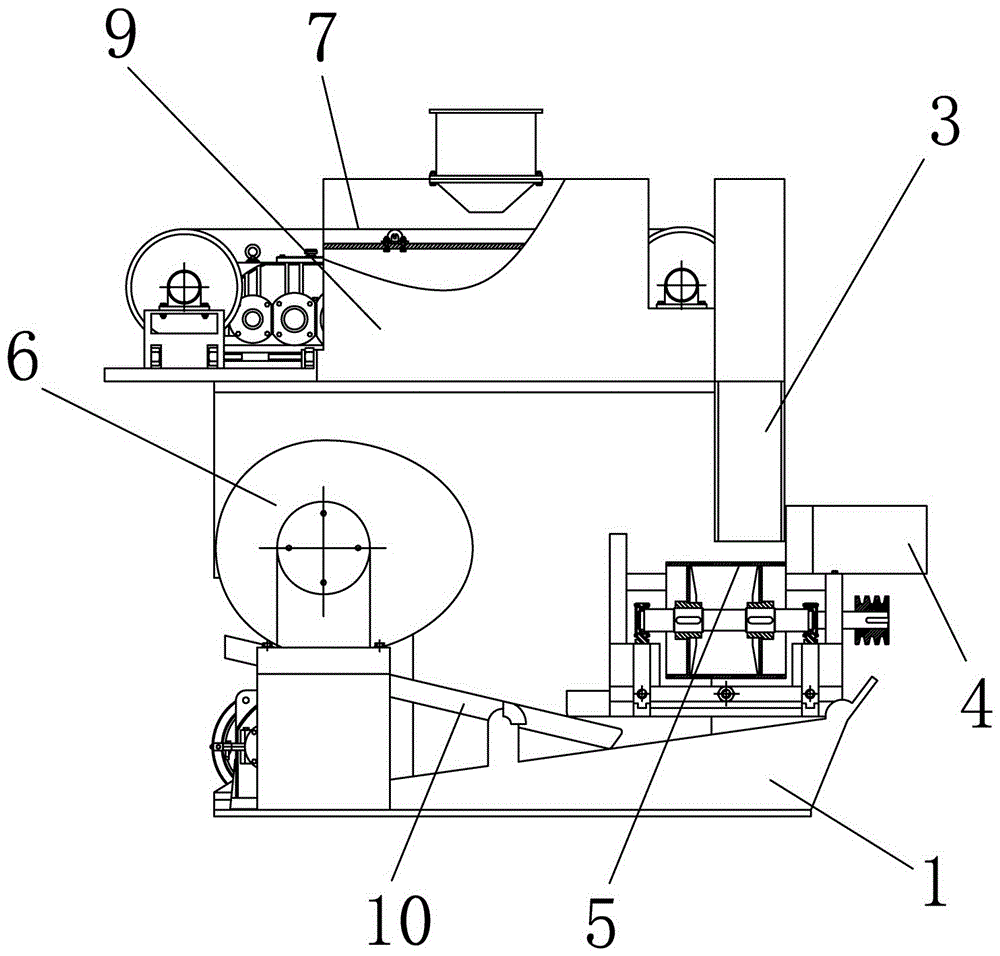

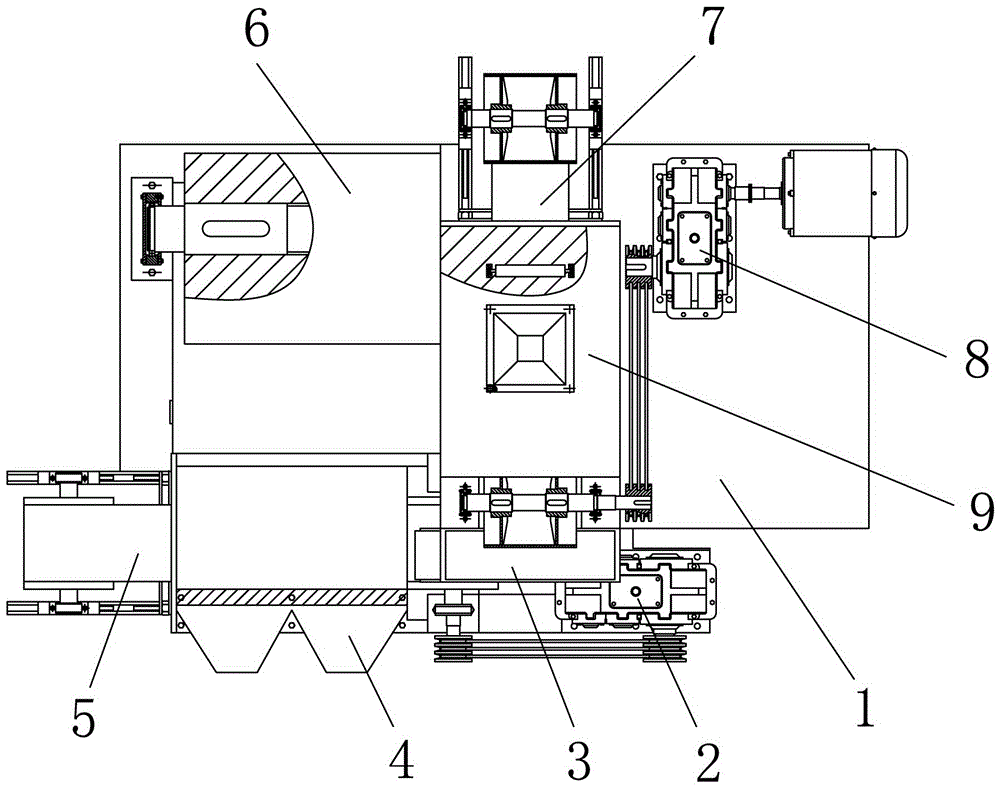

[0011] A semi-automatic feeding machine for sheep farms, such as figure 1 , figure 2 , image 3 Shown, comprise frame 1, electric motor, speed reducer 2,8 and conveyer belt device, described conveyer belt device is divided into feeding conveyer belt device 7 and discharge conveyer belt device 5 two parts, two parts conveyer belt devices are all made of The motor and the reducer are driven to rotate, and the feeding conveyor belt device passes through the feed bin 9, and a feed inlet is arranged above the feed bin 9. The discharge port 3 of the feeding conveyor belt device is located above the feed end of the discharging conveyor belt device 5, and the conveyor belt side of the discharging conveyor belt device is provided with a discharge port 4, and the base of the discharging conveyor belt device faces the discharge port. One end of the port is hinged at the lower part of the frame, and the lower part of the frame is also hinged with a lever 10. The other end of the base o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com