A clamping device that can cross around

A clamping device and fixture technology, which is applied in the direction of manufacturing rings from wires, other household appliances, household appliances, etc., can solve the problems of unoptimized trajectory, difficult to guarantee machining accuracy, and high strength of the traveler, so as to improve accuracy and stability, Reasonable device layout and large installation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below with reference to the drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation manners are given, but the protection scope of the present invention is not limited to the following embodiments.

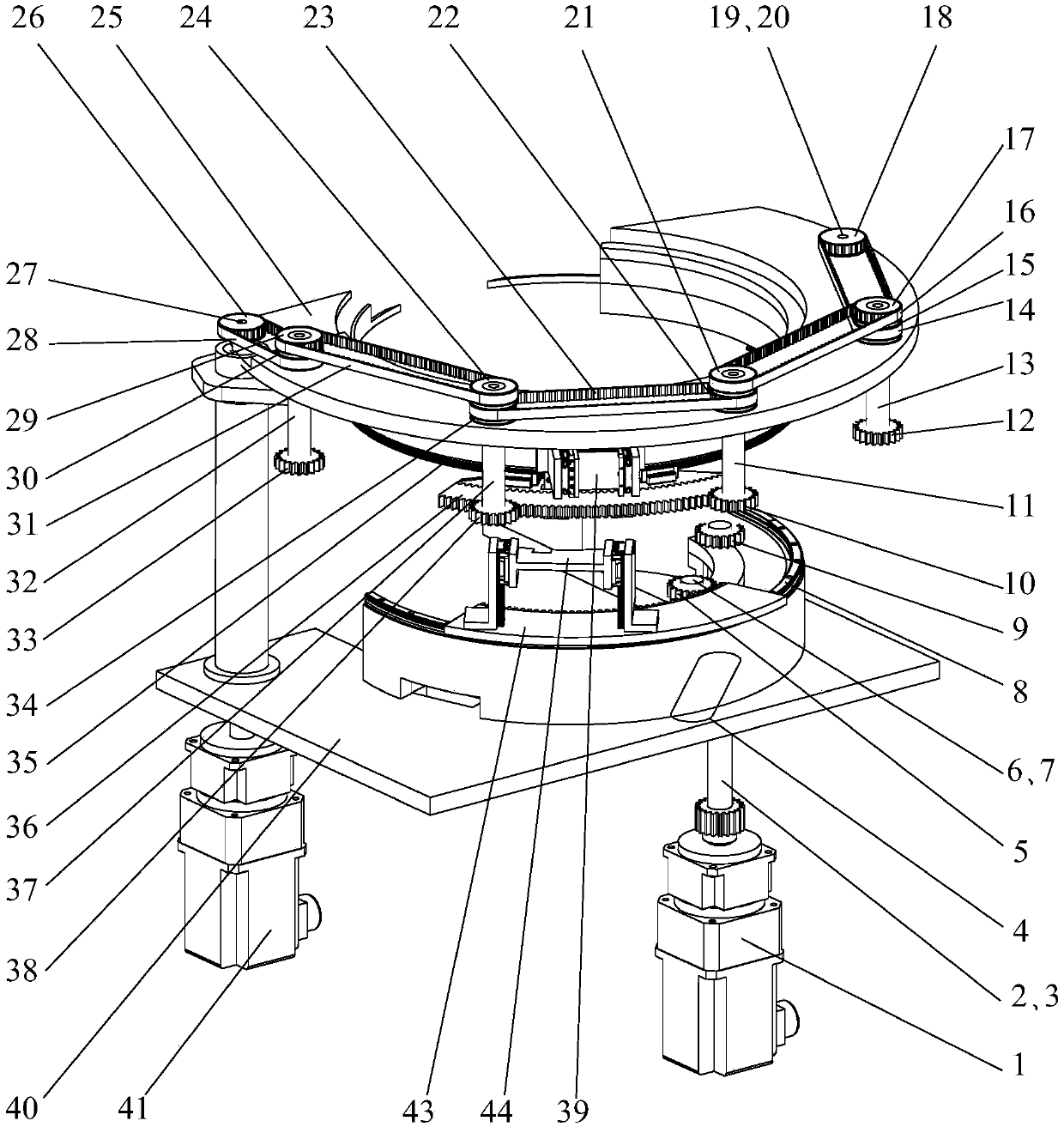

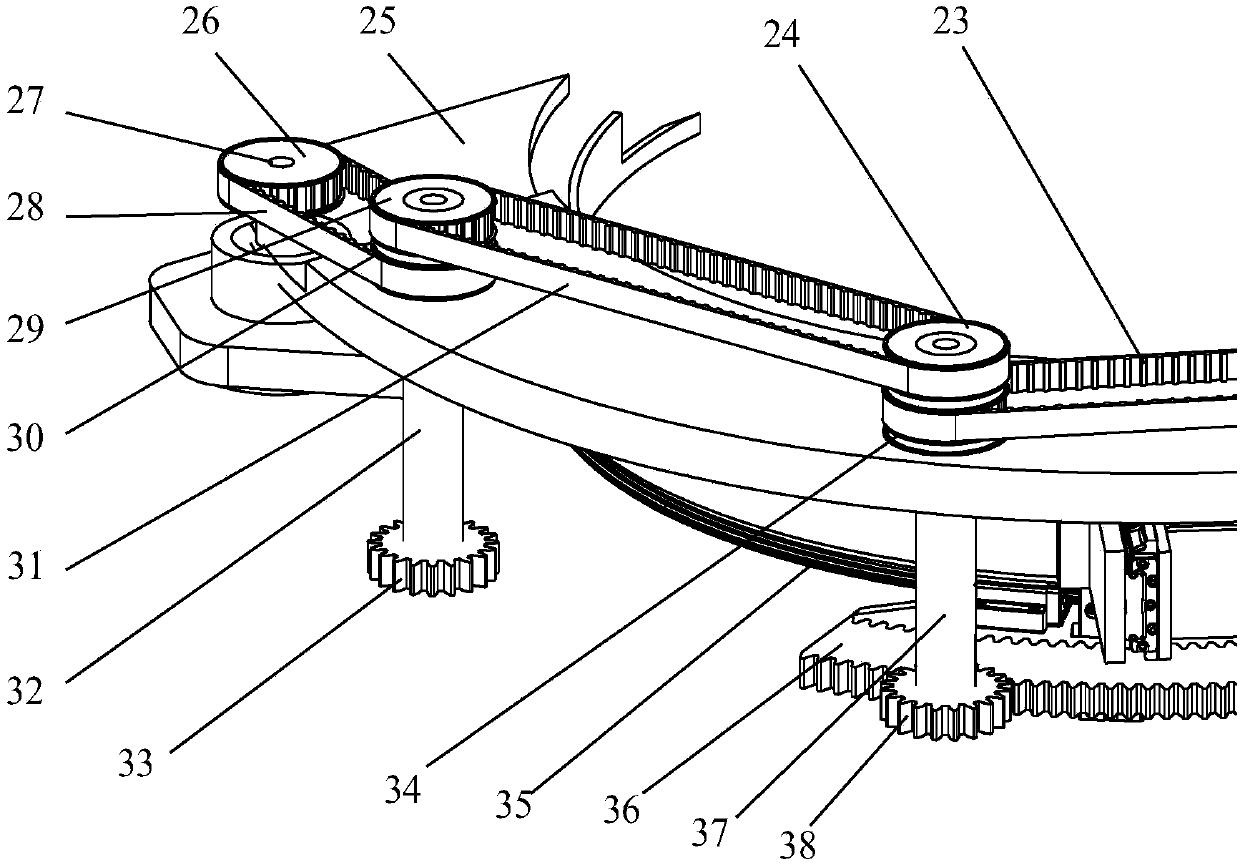

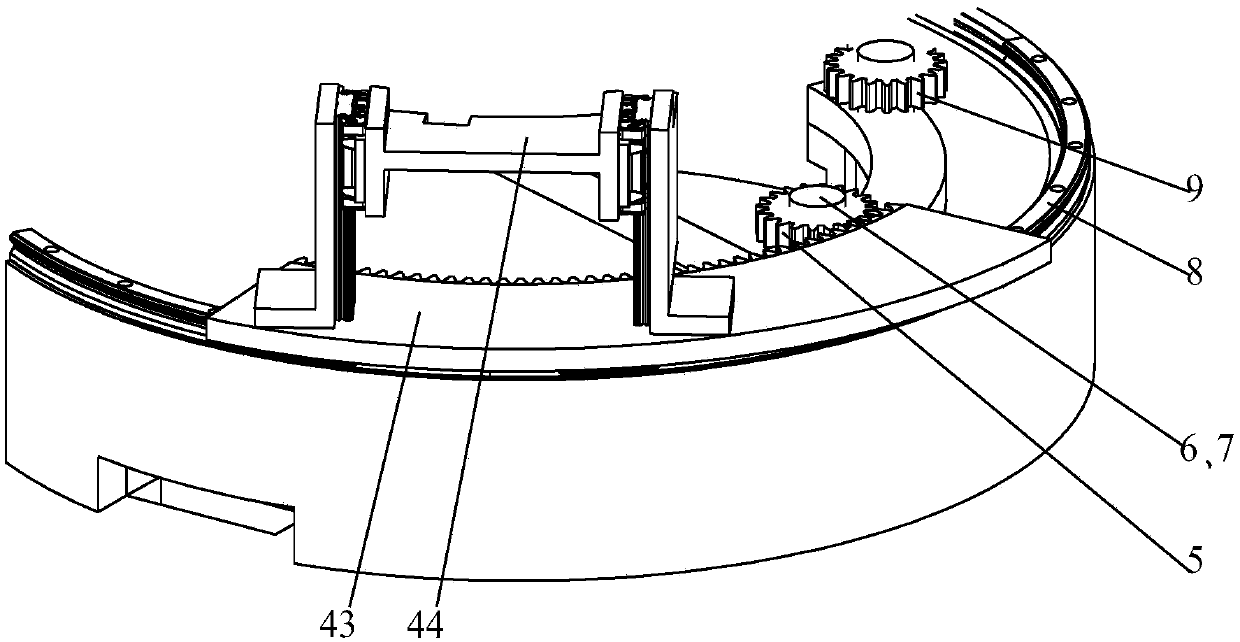

[0014] Such as Figure 1 ~ Figure 4 As shown, this embodiment relates to a clamping device that can be cross-wound, including: motor two 1, main shaft two 2, pulley twelve 3, toothed belt six 4, gear seven 5, shaft six 6, belt Wheel eleven 7, arc-shaped guide rail two 8, gear six 9, gear three 10, axis three 11, gear four 12, axis four 13, toothed belt four 14, belt wheel nine 15, toothed belt five 16, belt Wheel 8 17, belt wheel 10 18, shaft 5 19, gear 5 20, belt wheel 7 21, belt wheel 6 22, toothed belt 3 23, belt wheel 4 24, upper frame 25, belt wheel 1 26, spindle 1 27. Toothed belt one 28, belt wheel three 29, belt wheel two 30, toothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com