A quick replacement component for a manipulator

A manipulator and component technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of display rack bumping, damage to manipulators or multi-axis robots, time-consuming and laborious installation, etc., to avoid rigid contact, reduce input costs, and simplify The effect of input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

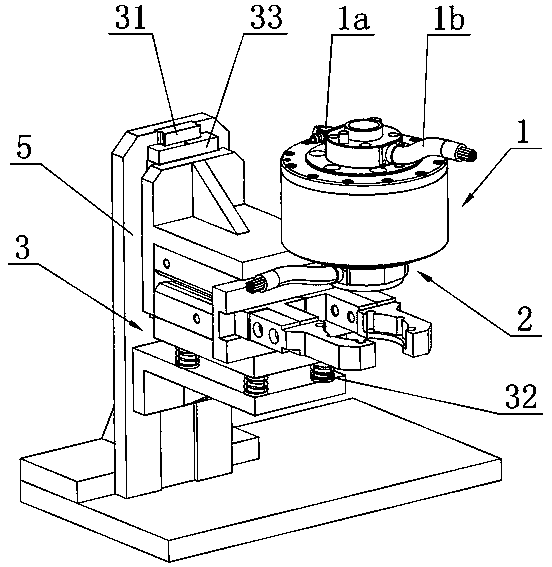

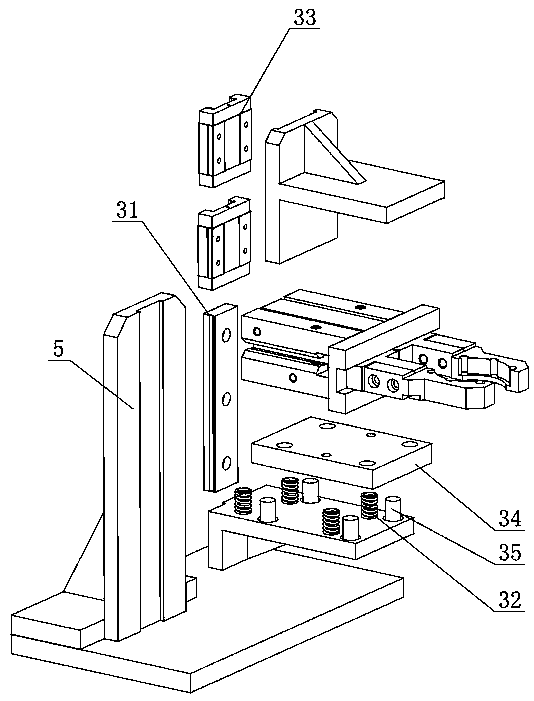

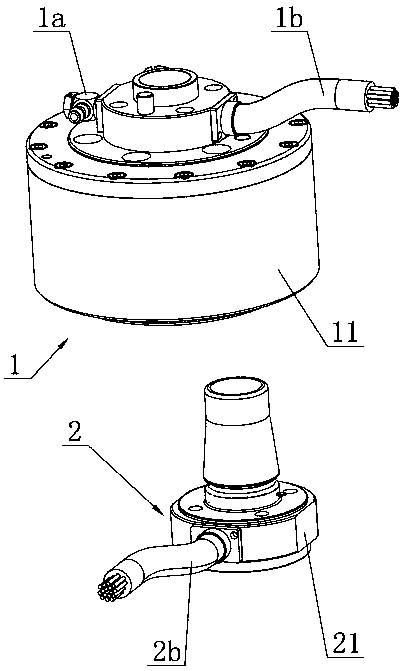

[0021] Such as Figure 1 to Figure 5 As shown, a quick replacement assembly for a manipulator includes a fixed connection device 1 installed on a robot arm, at least two replacement devices 2 and a locking mechanism for preventing the fixed connection device 1 from being loosened from the replacement device 2, and also includes a buffer mechanism 3. Replace the jaw 4 and the installation base 5. The buffer mechanism 3 includes a slide rail 31 fixed on the installation base 5, a buffer spring 32, a slide block 33 connected with the slide rail 31 and a floating installation table fixed to the slide block 33 34 , the two ends of the buffer spring 32 abut against the lower part of the floating installation platform 34 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com