Micro-cutting system suitable for hard and brittle materials and application of micro-cutting system

A technology for micro-cutting, hard and brittle materials, which is applied in the field of material processing and can solve the problems of difficulty in micro-cutting in the plastic domain of hard and brittle materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

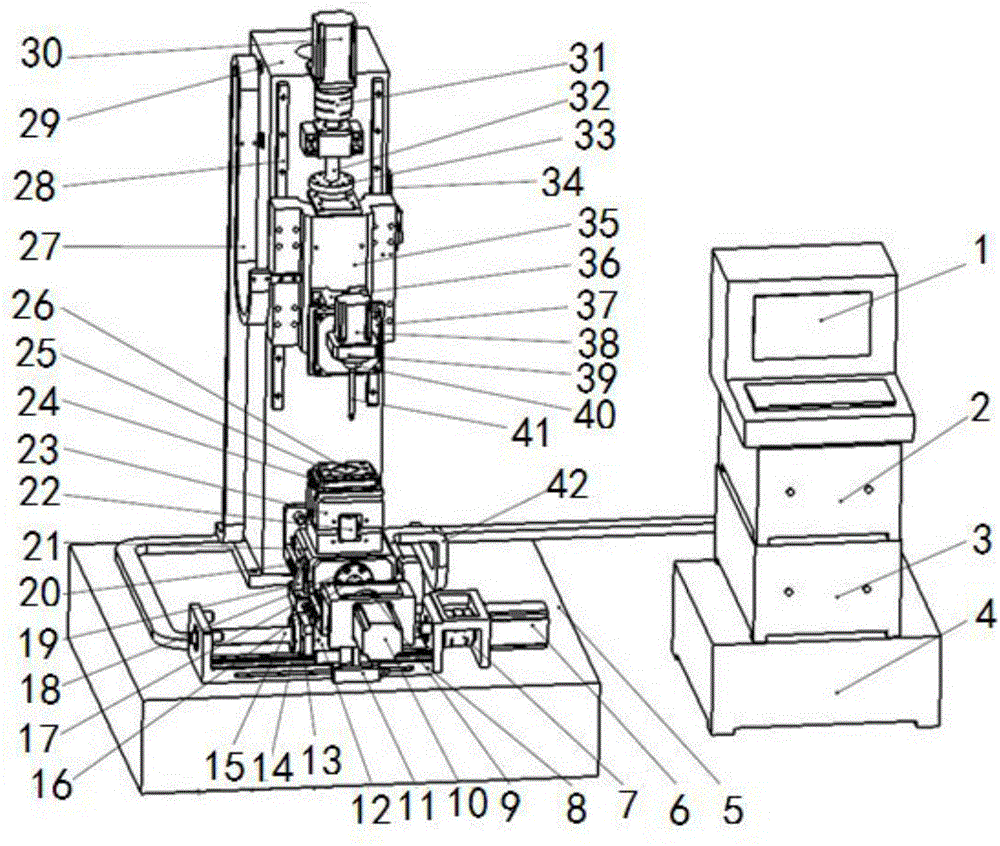

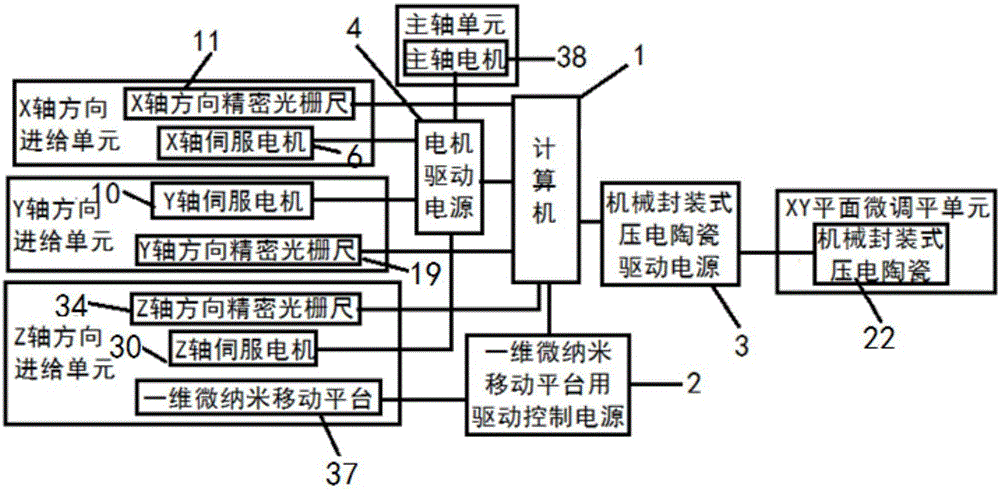

[0035] The present invention is applicable to the fine cutting processing system of hard and brittle materials, and its structure is as follows figure 1 As shown, it consists of a mechanical-detection integrated system and a control system connected by a drag chain a27 and a drag chain b42.

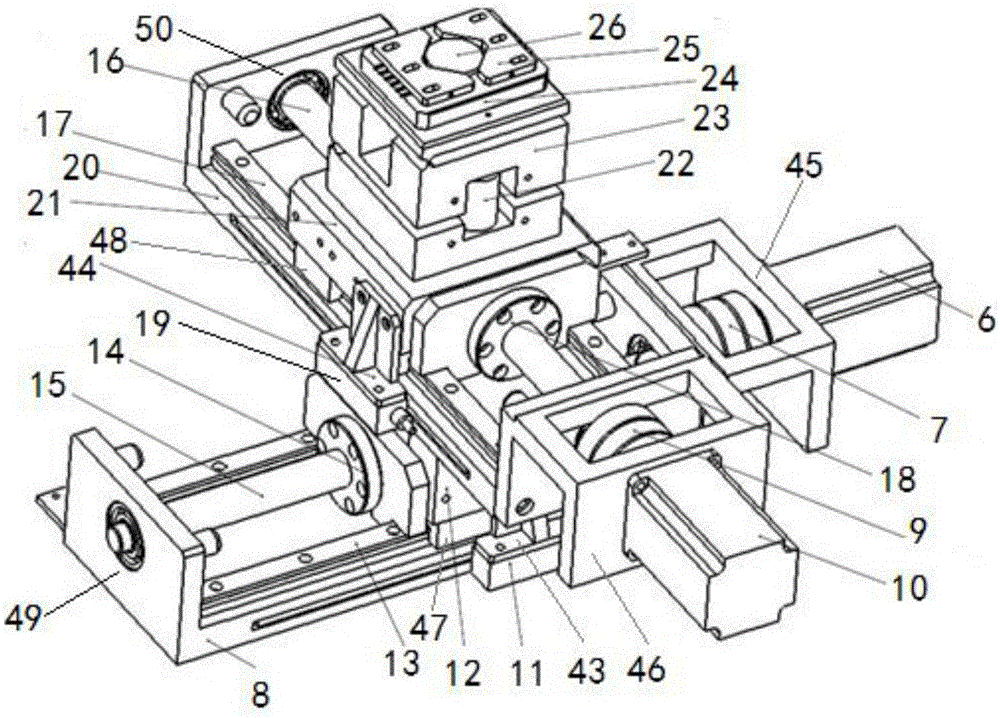

[0036] The mechanical-detection integrated system includes a fuselage body, the fuselage body is composed of a horizontally arranged base 5 and a column 29 vertically connected to the upper surface of the base 5; Feed unit, the X-axis direction feed unit is connected with the Y-axis direction feed unit, the Y-axis direction feed unit is provided with an XY plane fine-leveling unit, and the XY plane fine-leveling unit is provided with a workbench; The Z-axis direction feed unit and the spindle unit are respectively provided, and the Z-axis direction feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com