Coal hopper car whole group unloading control system

A control system and technology for hopper cars, which are applied to hopper cars, transportation passenger cars, railway car body parts, etc. and other problems, to achieve the effect of convenient connection, improving the efficiency of unloading, and reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

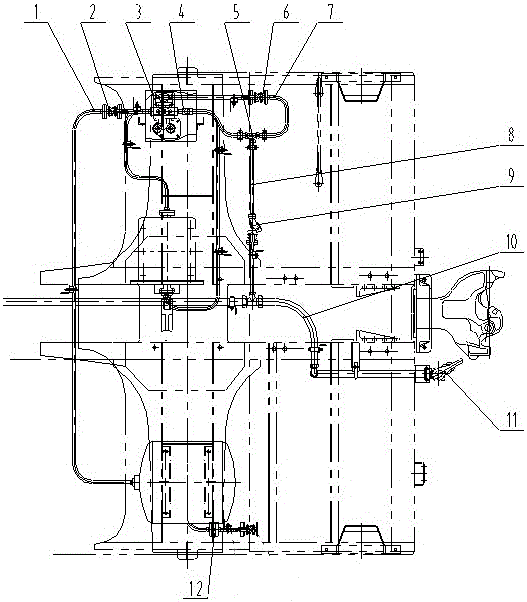

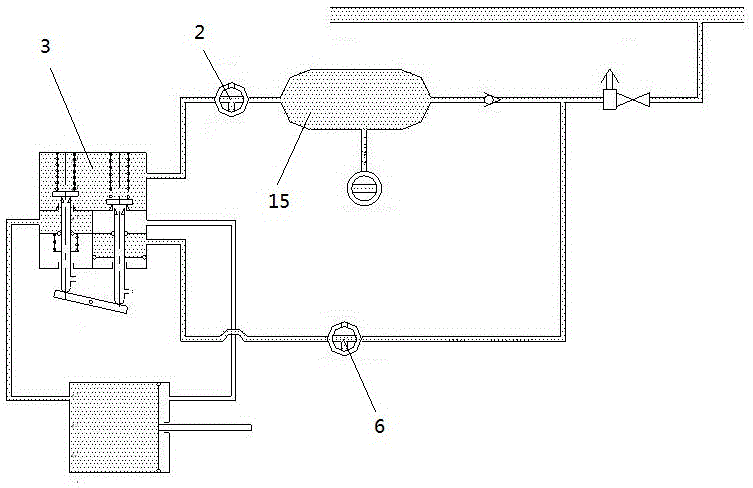

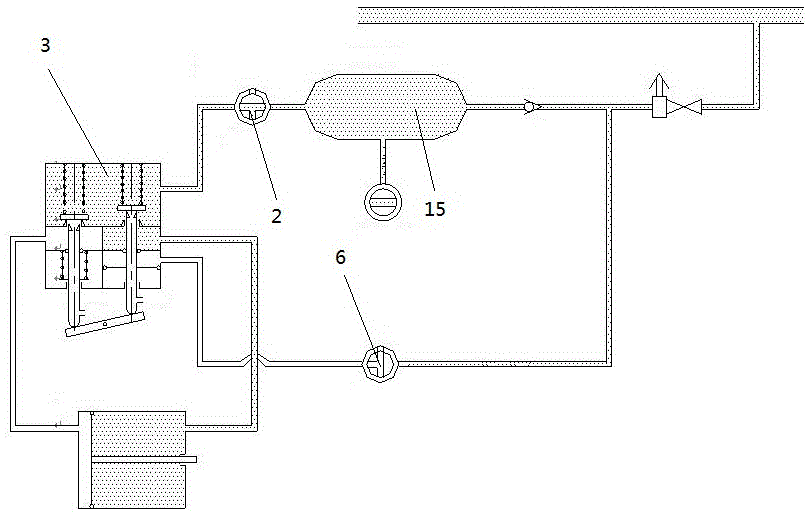

[0018] Such as figure 1 As shown, a coal hopper car unloading control system, including air storage cylinder branch pipe 1, exhaust plug door I2, action valve 3, check valve 4, tee joint 5, exhaust plug door II6, control pipe 7 , air inlet branch pipe 8, combined truncation plug door 9, main air inlet pipe 10, left-handed corner plug door 11 and air storage cylinder 15, air storage cylinder 15 communicates with exhaust air plug door I2 through air storage cylinder branch pipe 1, and air exhaust plug The door I2 communicates with the function valve 3, the function valve 3 communicates with the check valve 4, the check valve 4 communicates with the three-way joint 5, and the three-way joint 5 is respectively connected with the exhaust plug door II6 through the control pipe 7 and through the air inlet The branch pipe 8 communicates with the main air inlet pipe 10, the exhaust plug door II6 communicates with the function valve 3, a combined cut-off plug door 9 is arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com