a drinking bucket

A drinking water bucket and water dispenser technology, which is applied in the directions of packaging, closing, transportation and packaging, can solve the problems of inconvenience, unenvironmental protection, and inability to reseal the drinking water bucket, and achieve the effect of convenient installation or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

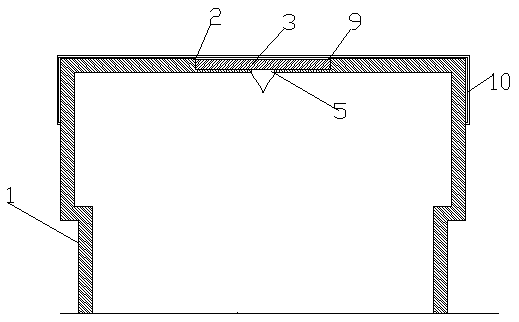

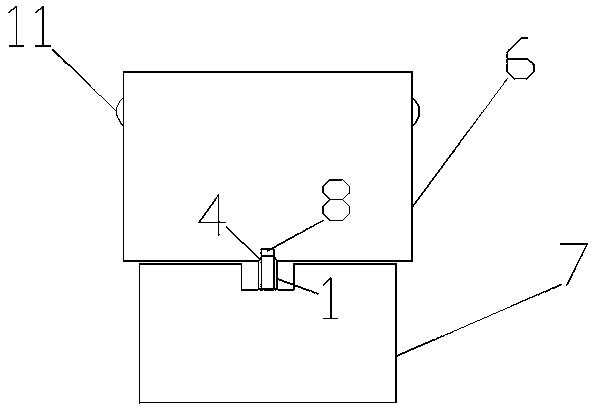

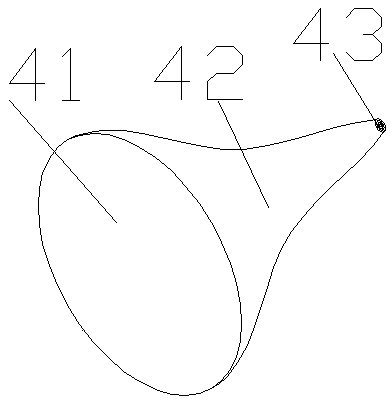

[0013] Such as figure 1 , 2 A kind of drinking water barrel shown in , 3, 4, comprises barrel body 6 and barrel head 1, and barrel head 1 is fixedly connected on the upper end of barrel body 6, and water outlet 5 is set on the barrel head 1, and the upper end of described water outlet 5 is set There is a groove 2, and the groove 2 is arranged in the middle of the upper end face of the barrel head 1. The diameter of the groove 2 can be adjusted according to the actual situation. The water inlet joint 8 is matched and set, the groove 2 is connected to the cover 3 by screw fixing, the cover 3 is provided with a rotating shaft 9, the rotating shaft 9 is a columnar protrusion, and the lower end of the water outlet 5 is fixed to the upper end of the hollow elastic rubber sleeve The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com