A kind of interface-enhanced machinable ceramic and preparation method thereof

A technology of interface enhancement and ceramics, which is applied in the field of ceramics, can solve problems such as cracking, chipping, and reduce the strength of ceramics, and achieve the effect of improving bending strength, high bending strength, and good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

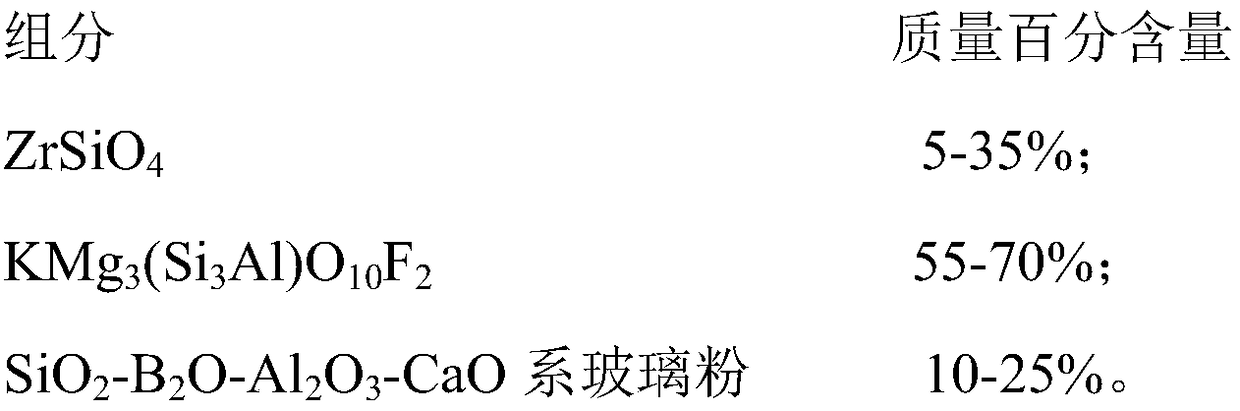

[0037] This embodiment provides a high-strength machinable mica glass-ceramic, the components of the mica glass-ceramic and their mass percentages are:

[0038]

[0039] This embodiment provides a new machinable mica glass-ceramic, which contains 5% ZrSiO by mass percentage 4 , 70% KMg 3 (Si 3 Al)O 10 f 2 and 25% SiO 2 -B 2 O-Al 2 o 3 -CaO-based glass powder, that is, 5% ZrSiO is added to the original fluorphlogopite glass ceramics 4 . Since ZrSiO 4 The network structure of the crystal can make it distributed between the layered interfaces of fluorphlogopite, increasing the bonding force between layers of fluorphlogopite without destroying its original layered structure, so , can improve the bending strength of fluorphlogopite glass ceramics without changing the machinability of fluorphlogopite ceramics, so that it is more suitable for industrial production and application.

[0040] ZrSiO in a kind of high-strength machinable mica glass-ceramics provided by the inv...

Embodiment 2

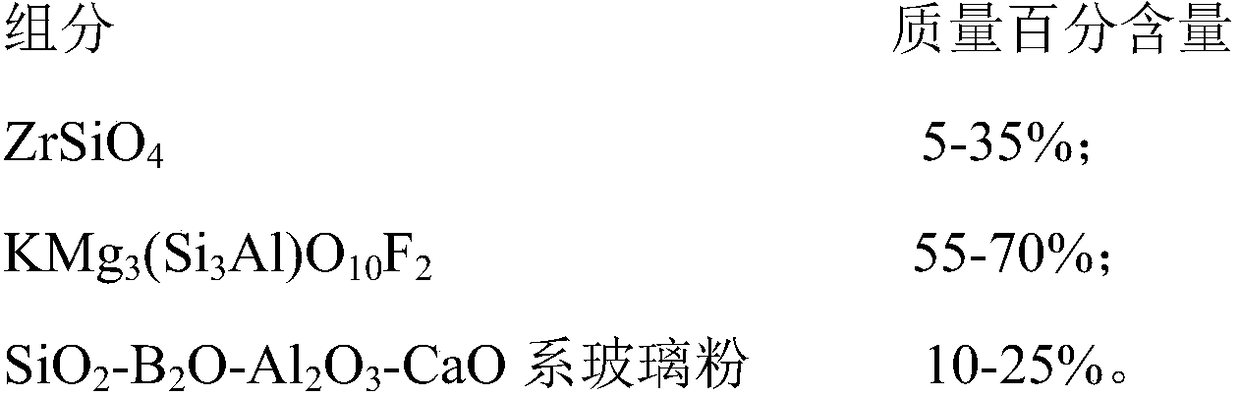

[0043] This embodiment provides a high-strength machinable mica glass-ceramic, the components of the mica glass-ceramic and their mass percentages are:

[0044] ZrSiO 4 35%;

[0045] KMg 3 (Si 3 Al)O 10 f 2 55%;

[0046] SiO 2 -B 2 O-Al 2 o 3 -CaO-based glass powder 10%.

[0047] ZrSiO in the processable mica glass ceramics in the present embodiment 4 The mass percentage of crystals is 35%.

[0048] Compared with Example 1, the present embodiment improves the ZrSiO in processable mica glass-ceramic 4 The mass percentage of crystals, at the same time, reduces the percentage of fluorphlogopite in ceramics and increases the ZrSiO 4 The combination of the network structure further improves the bending strength of the machinable mica glass ceramics.

[0049] ZrSiO in a kind of high-strength machinable mica glass-ceramics provided by the invention 4 The mass percentage of crystal should not be greater than 35%, because if ZrSiO 4 The content of crystals is too larg...

Embodiment 3

[0052] Compared with Example 2, the SiO described in this example 2 -B 2 O-Al 2 o 3 -In CaO-based glass powder, SiO 2 The mass percentage content is 51%; B 2 The mass percentage of O is 10%; Al 2 o 3 The mass percentage of CaO is 15%; the mass percentage of CaO is 24%.

[0053] This example further limits SiO in machinable ceramics 2 -B 2 O-Al 2 o 3 -The mass percentage of each component in the CaO-based glass powder.

[0054] After testing, the bending strength of the machinable mica glass-ceramic provided in this embodiment is 124MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com