Machining device and method for increasing single-yarn twist in siro-spinning

A processing device, a technology of siro spinning, applied in textiles and papermaking, etc., can solve the problems of small twist of single yarn, unexpected drafting, and many details, and achieve the effect of increasing twist of single yarn, improving strength, and reducing end breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

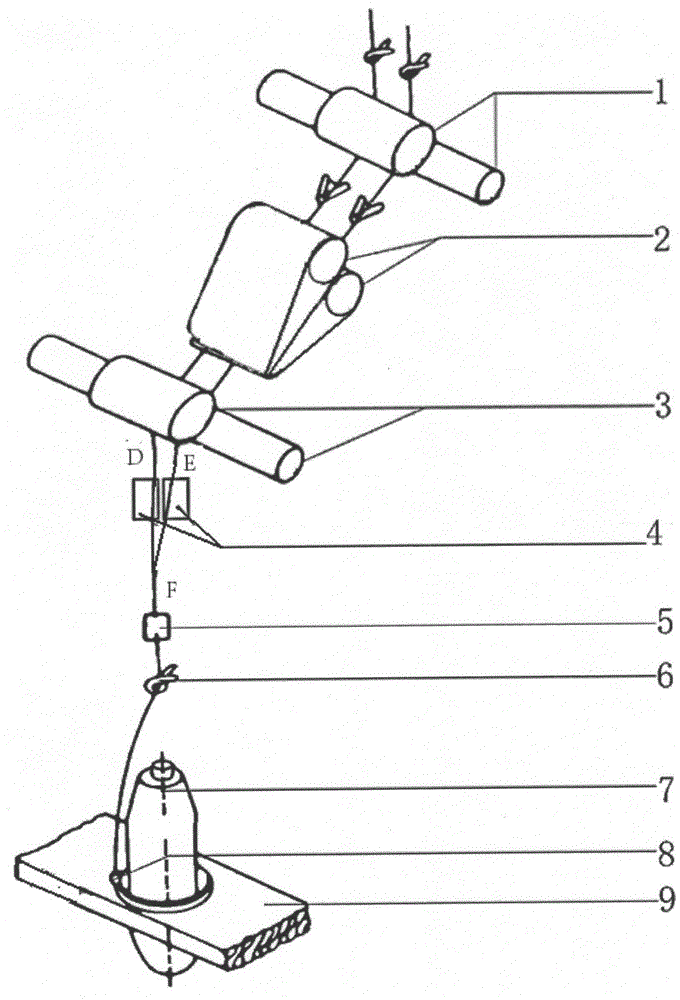

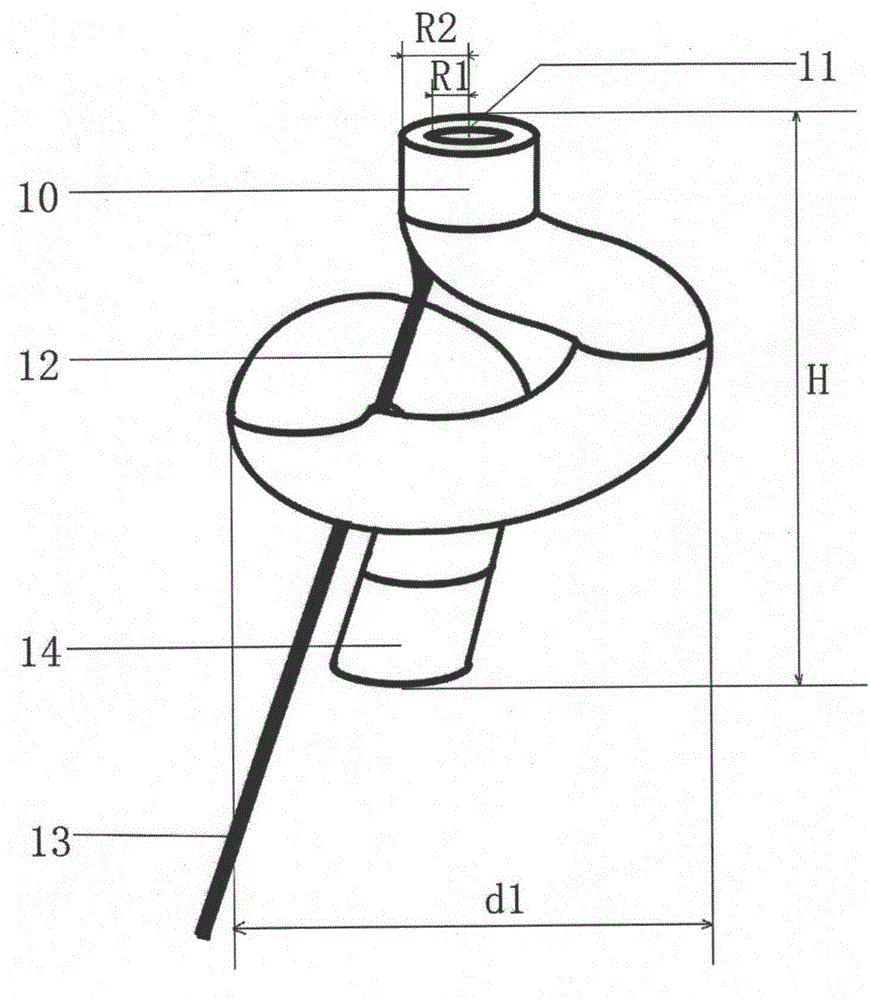

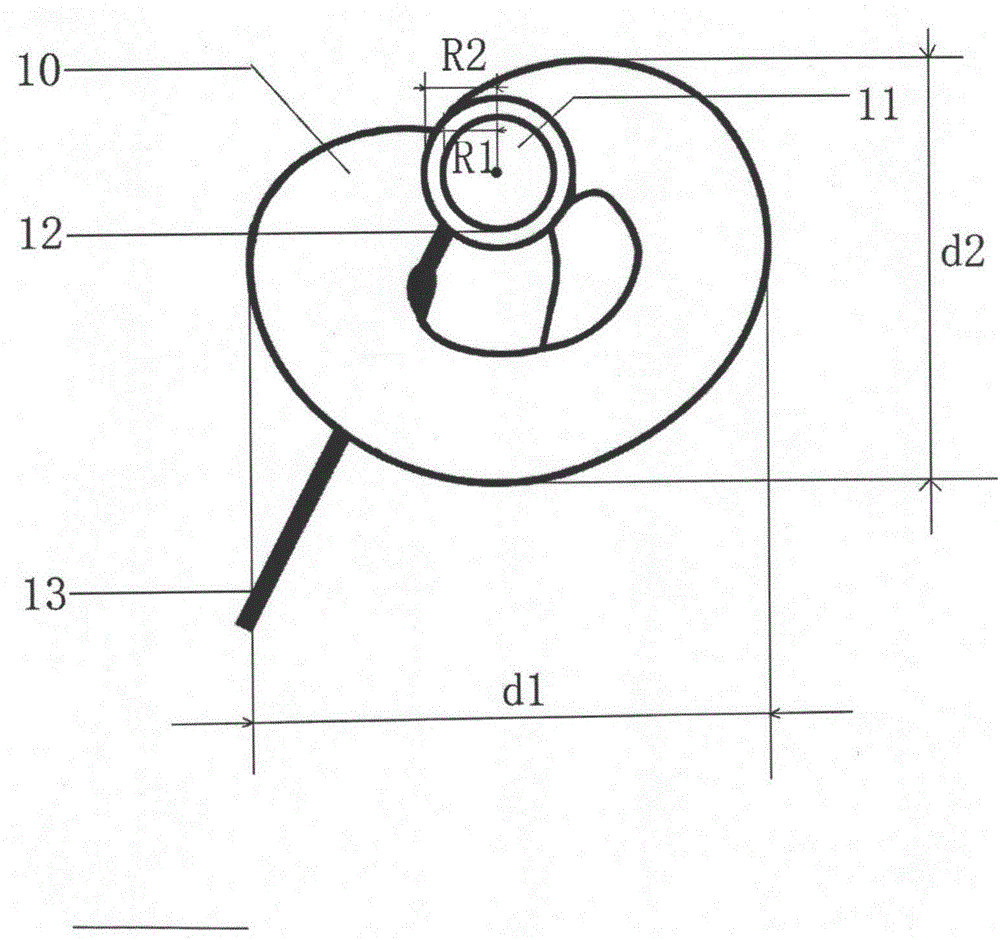

[0026] The roving weight of the roller after feeding is 8.5g / 10m. Using FA506 to improve the Siro spinning machine. The total draft ratio in the area from the front roller to the rear roller is 60, and the distance between the centers of the rollers in the front and rear draft areas is 40mm and 50mm respectively. After drafting, the distance between the two single yarn slivers when they are output from the front roller is 16mm. The trajectories DF and EF of the two single yarns converge symmetrically at the twisting convergence point F.

[0027] When the single yarn sliver passes through the special device of the present invention, the drive belt drives the rotary roller to rotate at a speed of 1500r / min. In the main body of the device, the overall height H is 10 mm, the length d1 is 5 mm, and the width d2 is 5 mm. The outer radius R2 of the sliver inlet and passage is 0.3 mm, and the inner radius R1 is 0.15 mm.

[0028] Spinning linear density is 56tex, the twin-spun yarn...

Embodiment 2

[0030] The roving weight of the roller after feeding is 6.5g / 10m. Using FA506 to improve the Siro spinning machine. The total draft ratio in the area from the front roller to the rear roller is 40, and the distance between the centers of the rollers in the front and rear draft areas is 50mm and 75mm respectively. After drafting, the distance between the two single yarn slivers when they are output from the front roller is 18mm. The trajectories DF and EF of the two single yarns converge symmetrically at the twisting convergence point F.

[0031] When the single yarn sliver passes through the special device of the present invention, the drive belt drives the rotary roller to rotate at a speed of 1300r / min. In the main body of the device, the overall height H is 13 mm, the length d1 is 8 mm, and the width d2 is 7 mm. The outer radius R2 of the sliver inlet and channel is 0.4 mm, and the inner radius R1 is 0.2 mm.

[0032] Spinning linear density is 60tex, the twist coefficie...

Embodiment 3

[0034] The roving weight of the roller after feeding is 4.0g / 10m. Using FA506 to improve the Siro spinning machine. The total draft ratio in the area from the front roller to the rear roller is 30, and the distance between the centers of the rollers in the front and rear draft areas is 55mm and 95mm respectively. After drafting, the distance between the two single yarn slivers when they are output from the front roller is 20mm. The trajectories DF and EF of the two single yarns converge symmetrically at the twisting convergence point F.

[0035] When the single yarn sliver passes through the special device of the present invention, the drive belt drives the rotary roller to rotate at a speed of 900r / min. In the main body of the device, the overall height H is 15 mm, the length d1 is 10 mm, and the width d2 is 8 mm. The outer radius R2 of the sliver inlet and channel is 0.45 mm, and the inner radius R1 is 0.5 mm.

[0036] Spinning linear density is 50tex, the twist coefficien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com