Anchoring plate, anchoring system and construction method

An anchoring system and anchoring plate technology, applied in bridge reinforcement, architecture, bridge construction, etc., can solve the problems of large construction space and difficult construction, and achieve the effects of quick and convenient construction, low reinforcement cost, and easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

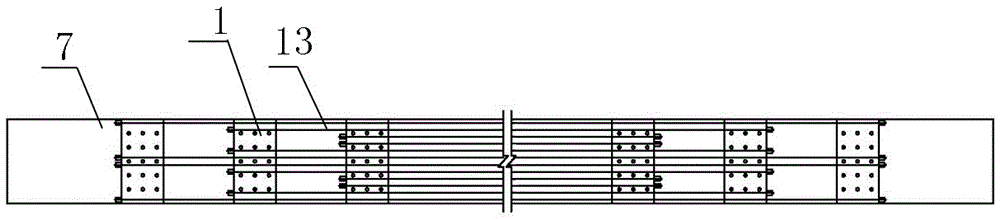

[0054] like Figure 14 and Figure 15As shown, this anchoring plate includes an anchoring plate main body 1, and on the lower surface of the anchoring plate main body 1, four long anchoring notches 2 passing through prestressed steel wires 13 are spaced apart in parallel; the anchoring plate main body 1 There are grooves 3 on one end surface corresponding to the position of the full-length anchoring notch 2; there are four grooves 3, which are symmetrically distributed on both sides of the longitudinal axis; on the anchor plate main body 1, along the anchor plate main body Bolt holes 4 are spaced apart in the thickness direction of 1 .

[0055] In this embodiment, the main body 1 of the anchor plate is a rectangular steel plate; the full-length anchor notches 2 are parallel to the longitudinal axis of the rectangular steel plate, and four full-length anchor notches 2 are arranged along the transverse axis of the rectangular steel plate.

Embodiment 2

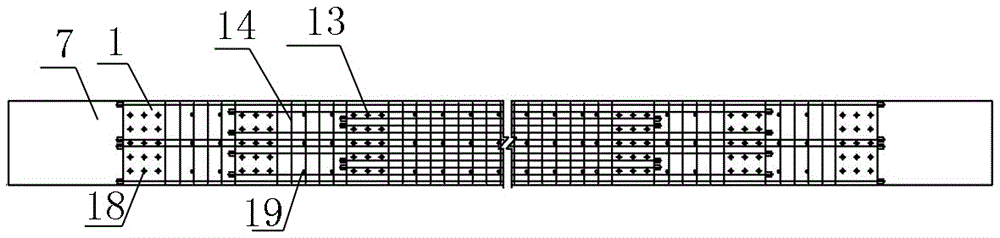

[0057] like Figure 16 and Figure 17 As shown, this anchoring plate includes an anchoring plate main body 1, and on the lower surface of the anchoring plate main body 1, four long anchoring notches 2 passing through prestressed steel wires 13 are spaced apart in parallel; the anchoring plate main body 1 There are grooves 3 on one end surface corresponding to the position of the full-length anchoring notch 2; there are four grooves 3, which are symmetrically distributed on both sides of the longitudinal axis; on the anchor plate main body 1, along the anchor plate main body Bolt holes 4 are spaced apart in the thickness direction of 1 .

[0058] In this embodiment, the main body 1 of the anchor plate is a rectangular steel plate; the full-length anchor notches 2 are parallel to the longitudinal axis of the rectangular steel plate, and four full-length anchor notches 2 are arranged along the transverse axis of the rectangular steel plate.

[0059] In this embodiment, four lon...

Embodiment 3

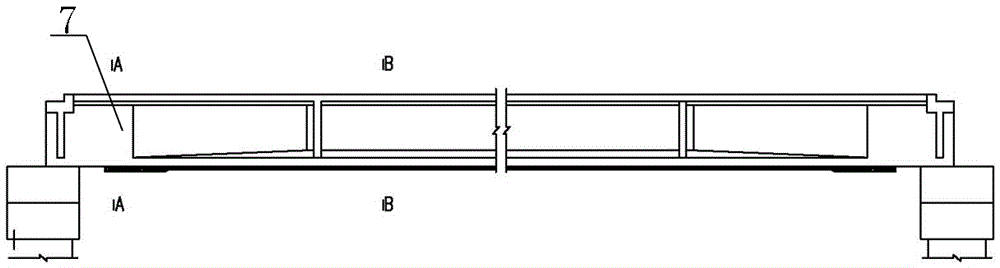

[0061] like Figure 18 and Figure 19 As shown, this anchoring plate includes an anchoring plate main body 1, and on the lower surface of the anchoring plate main body 1, four long anchoring notches 2 passing through prestressed steel wires 13 are spaced apart in parallel; the anchoring plate main body 1 There are grooves 3 on one end surface corresponding to the position of the full-length anchoring notch 2; there are four grooves 3, which are symmetrically distributed on both sides of the longitudinal axis; on the anchor plate main body 1, along the anchor plate main body Bolt holes 4 are spaced apart in the thickness direction of 1 .

[0062] In this embodiment, the main body 1 of the anchor plate is a rectangular steel plate; the full-length anchor notches 2 are parallel to the longitudinal axis of the rectangular steel plate, and four full-length anchor notches 2 are arranged along the transverse axis of the rectangular steel plate.

[0063] In this embodiment, there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com