Bomb quick unsealing docking device

A docking device and fast technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of low efficiency of ammunition support, unfavorable combat effectiveness, and high labor intensity of maintenance personnel, achieving high military economic benefits, enhancing combat effectiveness, reducing The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

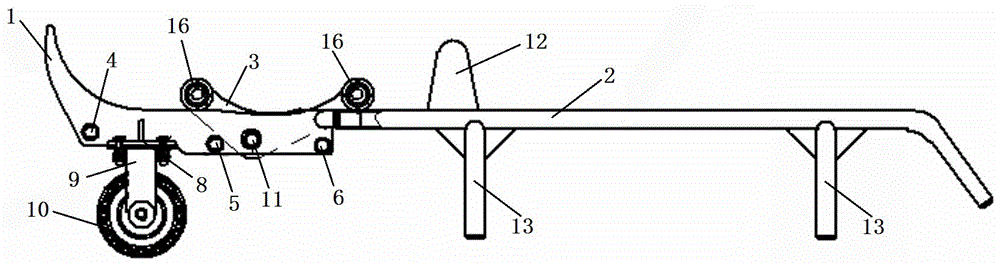

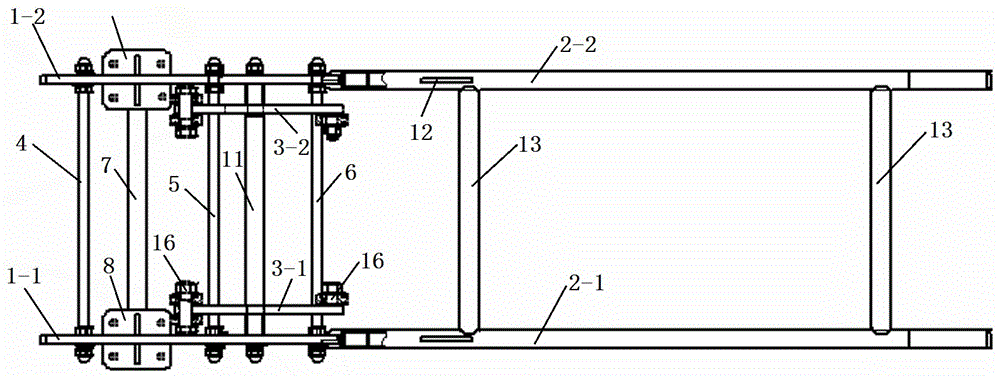

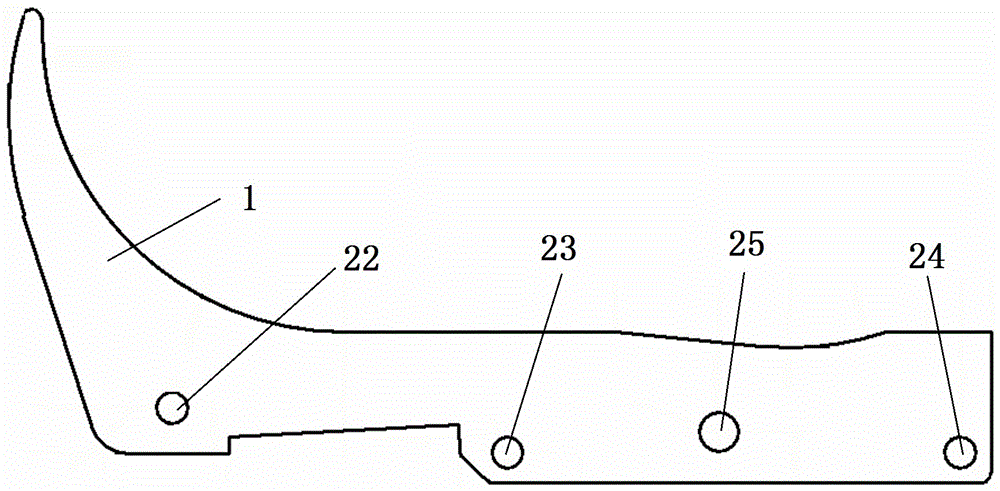

[0026] Embodiment: A quick unsealing docking device for a bomb, including a docking vehicle and a jacking column tool, the docking vehicle includes a guide plate 1, a handle 2 and a spring support plate 3, and the guide plate 1 includes a left guide plate 1-1 and a right guide plate 1-2, handle 2 includes left handle 2-1 and right hand handle 2-2, left guide plate 1-1 and right guide plate 1-2 are respectively connected with left handle 2-1 and right hand handle 2-2, left guide The first connecting rod 4, the second connecting rod 5 and the third connecting rod 6 are respectively arranged between the plate 1-1 and the right guide plate 1-2, and the first connecting rod 4 and the second connecting rod 5 are arranged in parallel The connecting shaft 7, the two ends of the connecting shaft 7 are respectively provided with a fixed plate 8, the fixed plate 8 is connected with the wheel 10 through the connecting plate 9, and a supporting spring plate shaft 11 is arranged in parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com