Traceable intelligent titrating device and traceable intelligent titrating method

A titration device and titration technology, which is applied in the direction of chemical analysis by titration, can solve the problems of inconvenient experimental work, difficult to grasp the precision, and inconvenient audit and review, and achieve the effect of convenient use, simple structure, and convenient review and audit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

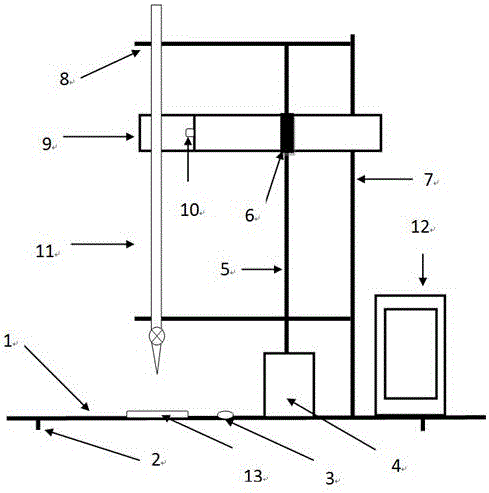

[0032] Before titration, enter the solution temperature, burette calibration curve, blank calibration value, sample volume, dilution factor and other information into the data processing terminal, and perform titration according to the method. During titration, manually add titrant to the burette to adjust the liquid level At or slightly below zero, the initial reading is determined through the automatic reading module, and the photos are kept, and the titration is started according to the method. Calculate the volume of the titrant used, and perform blank, temperature and burette calibration, automatically calculate the results according to the formula and related data, store and upload to the LIMS system.

Embodiment 2

[0034] Before titration, enter the solution temperature, burette calibration curve, blank calibration value, sample volume, dilution factor and other information into the data processing terminal, and perform titration according to the method. During titration, manually add titrant to the burette to adjust the liquid level At zero point or slightly below zero point, the initial reading is determined through the automatic reading module, and the photo is saved, and the titration is started according to the method, and the image and color are collected through the end point judgment module. Compare, judge the end point, and save the image information at the initial and end points. When the end point is reached, the end point reading is determined again through the automatic reading module, and the photo is saved. The data processing terminal automatically calculates the volume of the titrant used, and performs blank, temperature, and burette calibration , automatically calculate ...

Embodiment 3

[0036] Select the titration mode in the data processing terminal, and input the solution temperature, burette calibration curve, blank calibration value, sample volume, dilution factor and other information into the data processing terminal;

[0037] Automatically add titrant to the burette through the infusion pump. When the liquid level is at or slightly below zero, the photosensitive sensor and image collector will sense that the liquid level reaches the initial position, and control the infusion pump to stop the infusion through the data processing terminal;

[0038] Before titration, according to the requirements of the detection method, add an indicator, determine the initial reading through the automatic reading module, collect the initial image and color data of the sample solution through the end point judgment module, and store them in the memory of the data processing terminal;

[0039] Start the titration. During the titration process, the photosensitive sensor and im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com