Hawthorn fruit kernel removing and slicing all-in-one machine

An all-in-one machine and core slicing technology, which is applied in fruit pitting devices, metal processing, food science, etc., can solve the problems that manual slicing cannot meet the production needs, cannot meet the requirements of hawthorn slices, and is not suitable for hawthorn production, etc., and achieve labor saving The effect of labor, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

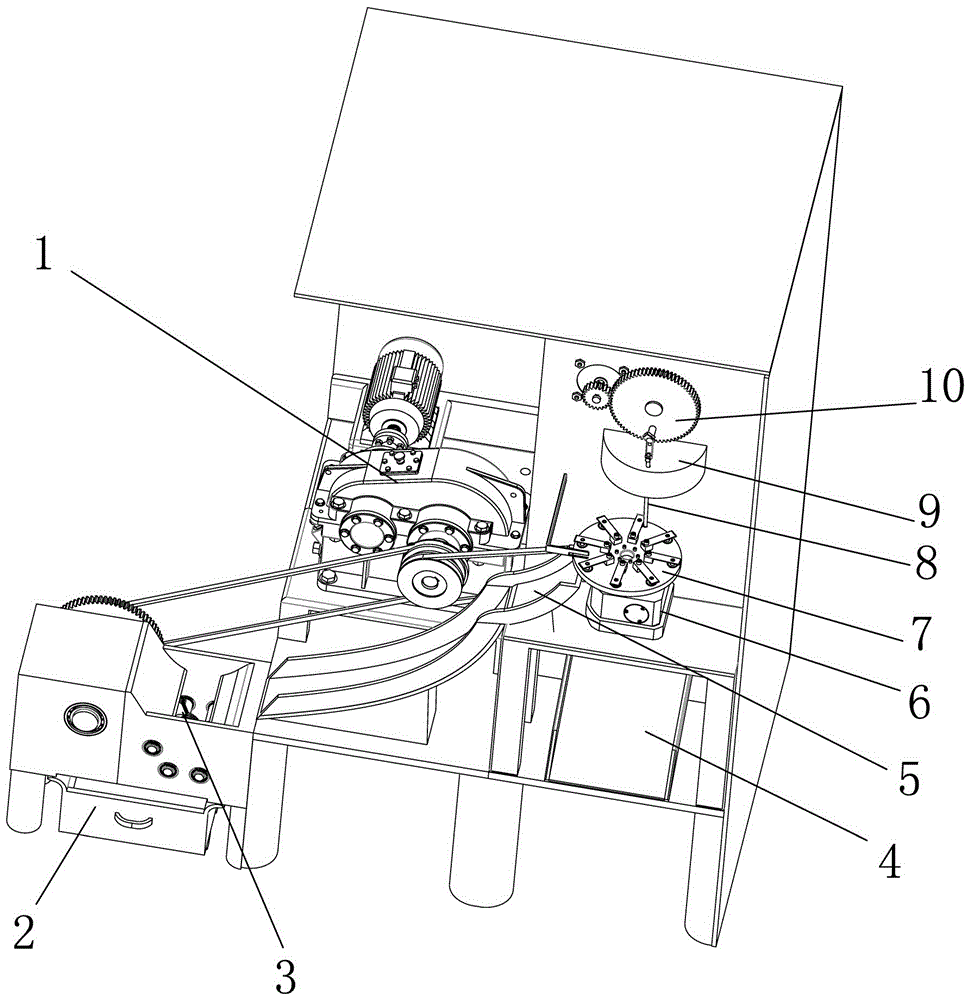

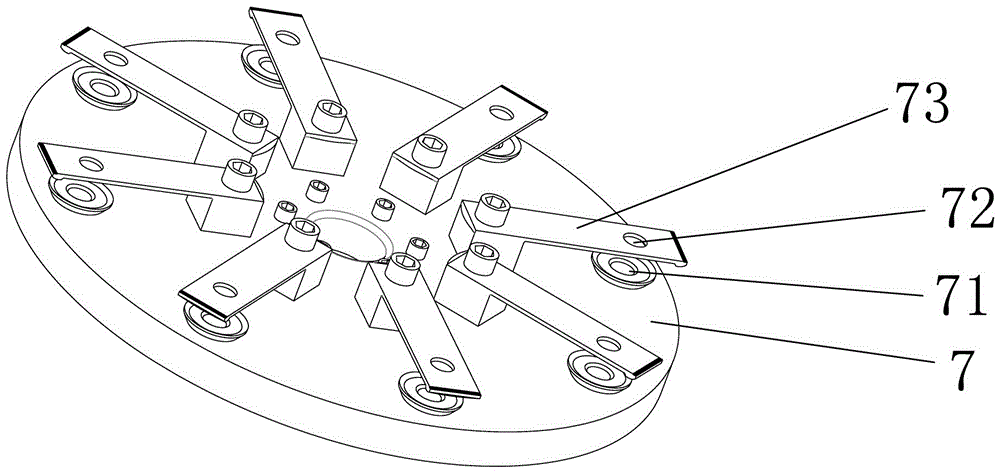

[0013] A kind of all-in-one machine for removing core and slicing hawthorn, such as figure 1 , 2 , 3, and 4 shown, including the motor drive control mechanism 1 installed on the frame, the coring mechanism and the slicing device, the coring mechanism includes a crank connecting rod, hawthorn rotating disc 7 and a cam divider 6, so The lower end of the connecting rod 8 constitutes a nuclear cutter head, the connecting rod 8 passes through the guide plate 9, and the upper end of the connecting rod 8 is eccentrically connected with a transmission gear 10 through a crank. When the transmission gear 10 rotates, it drives the connecting rod 8 to move up and down; the hawthorn rotates A blanking chute 5 communicating with the slicing device 3 is arranged below the side of the disk 7 , and a hopper 2 is arranged below the slicing device 3 .

[0014] Hawthorn core blanking trough 4 is arranged on the side of the frame below the hawthorn rotating disc 7 .

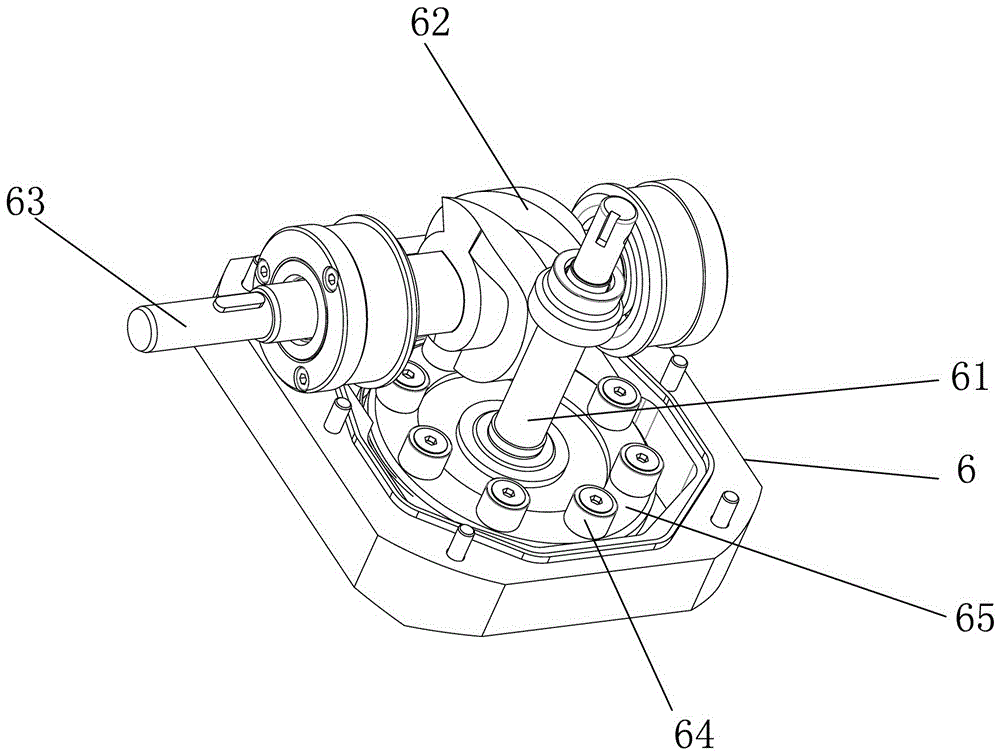

[0015] The cam splitter 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com