Cage rod of cage shaft

A rod body and rod insertion technology, which is used in applications, food processing, food science, etc., can solve the problems of wasting water, irregular volume and shape of sweet potatoes, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

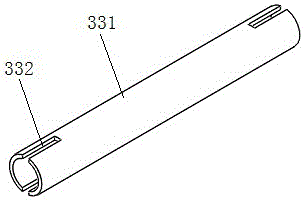

[0021] In order to further illustrate the technical scheme of the present invention, now in conjunction with accompanying drawing, illustrate the specific implementation manner of the present invention; Figure 4 , select diameter 10 millimeters in this example, the steel pipe of wall thickness 1 millimeter is used as bar 331, in order to reduce the weight of bar 331 like this; Select the width 2 millimeters of draw-in groove 332, depth 10 millimeters, insert and extract in order to make latch 31 convenient like this; In this way, the implementation of the rod body 31 is completed.

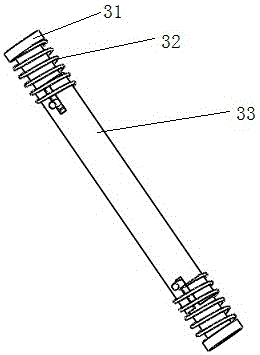

[0022] Such as image 3 In this example, the diameter of the end cover 311 is 12 millimeters and the thickness is 2 millimeters, and the pin shaft 312 is 8 millimeters in diameter and 30 millimeters in length; One end of the pin shaft 312 is arranged perpendicular to the pin shaft 312, and the bayonet pin 313 is vertically installed on the other end of the pin shaft.

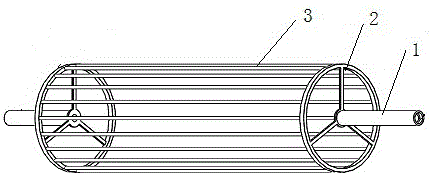

[0023] Such as figure 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com