Tray emptying station for emptying trays filled with rod-shaped articles and method for emptying a tray filled with rod-shaped articles by means of a tray emptying station

A technology for emptying stations and trays, applied in applications, tobacco, cigarette manufacturing, etc., can solve problems such as acceleration, emptying of trays without public disclosure, and slow station emptying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

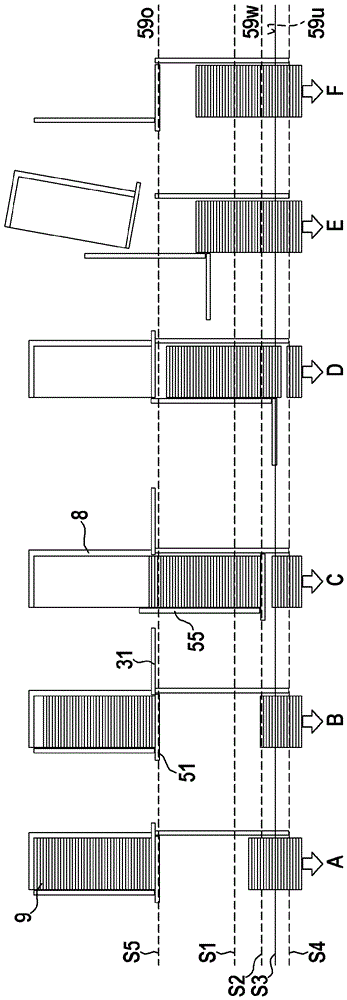

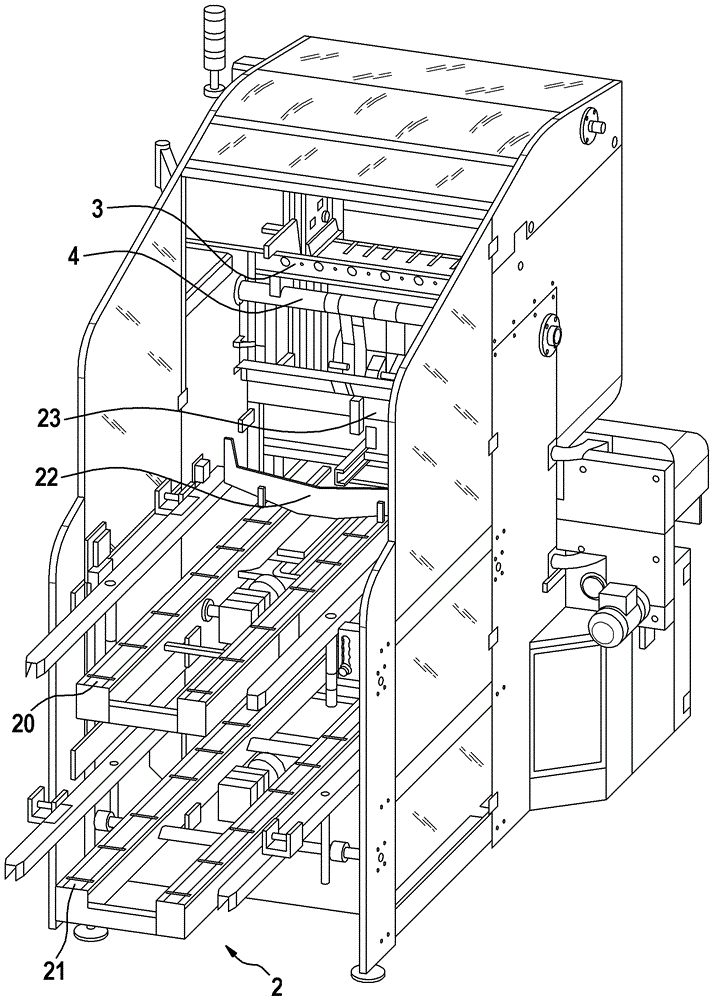

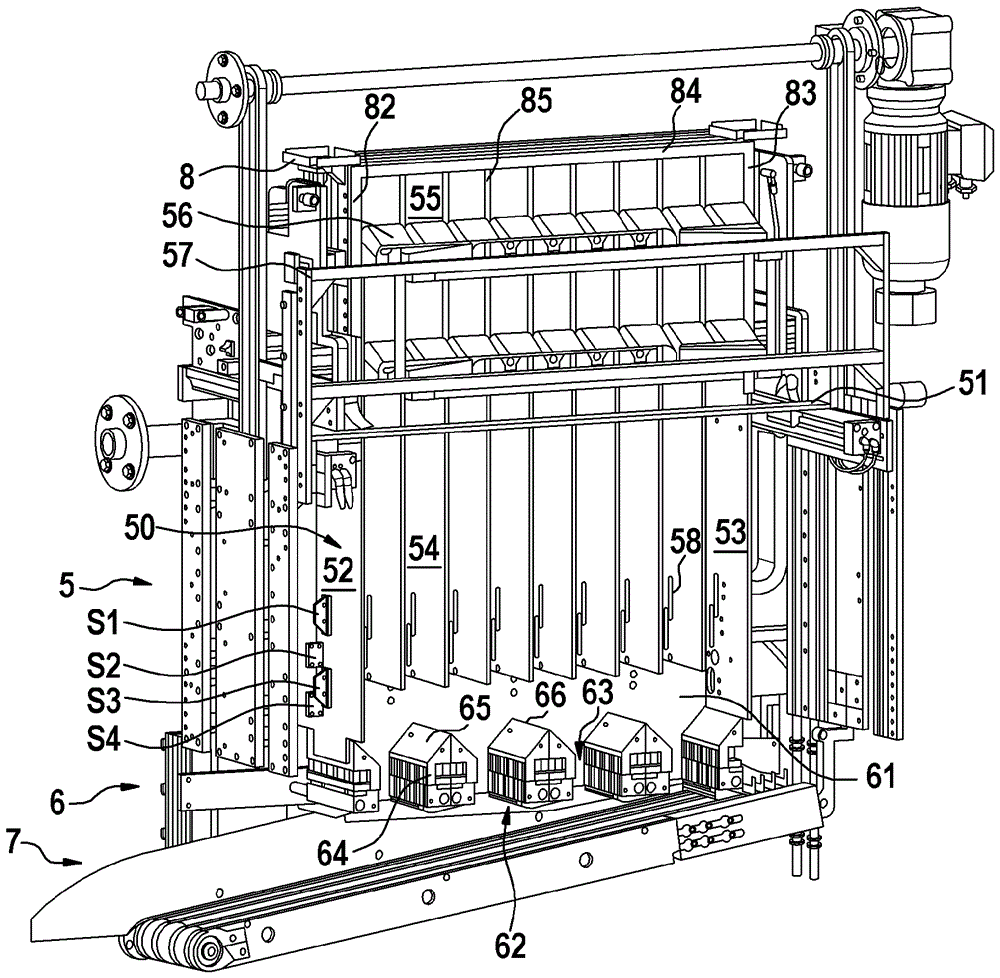

[0078] According to an embodiment, the tray emptying station 1 generally comprises a transfer device 2 for moving into or out of trays (shown in figure 1 middle), box 3 for receiving trays (shown in figure 1 middle), transport device 4 for the box (shown in figure 1 middle), memory area 5 used as a buffer (shown in figure 2 and 3 middle), receiving space 6—in this receiving space the rod-shaped products are arranged in a continuous mass flow (shown in figure 2 and 3 ), and the conveying element 7 by which the mass flow is transported away from the tray emptying station (shown in figure 2 and 3 middle).

[0079] figure 1 Rear view of the tray emptying station with transfer device 2 , cassette 3 and transport device 4 is shown. The transfer device 2 consists of a full tray station 20 and an empty tray station 21 . In the full tray station 20 , the trays filled with rod-shaped products are transported by means of a conveyor belt to the cassette 3 , are received in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com