Automatic bead stringing robot

A robotic and automatic technology, applied in the field of robotics, can solve problems such as low efficiency and labor occupation, and achieve the effect of reducing manpower demand and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

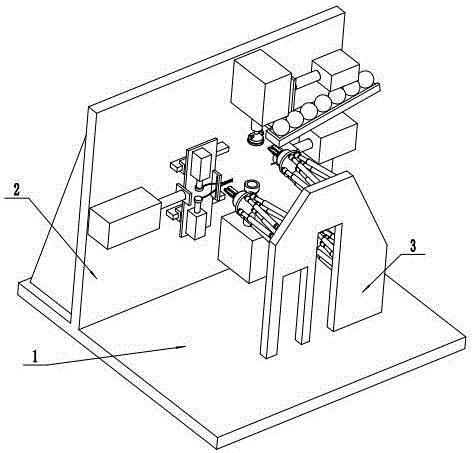

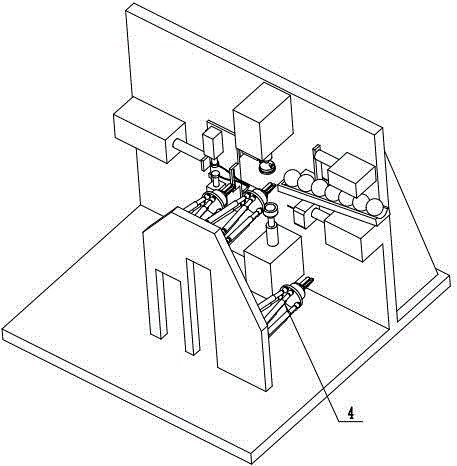

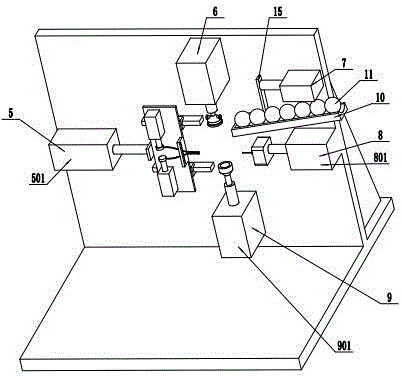

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, an automatic beading robot includes a bottom plate 1, a fixed seat 2, a manipulator support 3, three manipulators 4, a threading module 5, an adsorption module 6, a first cylinder 7, a drilling module 8, a support module 9, and a storage Groove 10, first guide rail 12, first slide block 13, storage tank support 14, connecting rod 15, it is characterized in that: described base plate 1 upper end surface is vertically installed with fixing seat 2, manipulator support 3, manipulator support The seat 3 is located in front of the fixed seat 2; the three manipulators 4 are installed on the manipulator support 3 through the main base 401; the threading module 5 is installed on the left side of the fixed seat 2, and the adsorption module 6 is installed on the fixed seat 2 Above, the drilling module 8 is installed on the right side of the fixing seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com