Dinner plate cleaning device

A technology for cleaning devices and dishes, which is used in household cleaning devices, washing machines/washing machines for tableware, parts of washing machines/rinsing machines for dishes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

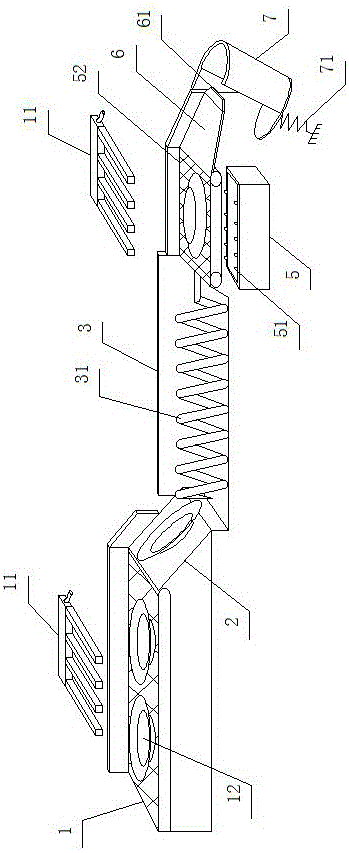

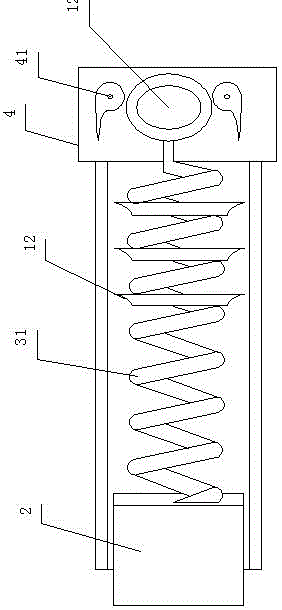

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] like figure 1 and figure 2 As shown, the present invention provides a dish cleaning device, which includes a conveyor belt device 1 for placing the dinner plate. The conveyor belt device transports the dinner plate 12 forward. There is a shower head 11 for spraying pre-washing liquid, so that the pre-washing liquid on the top of the dinner plate can be sprayed onto the dinner plate for pretreatment earlier in the process of forward transport. The end of the conveyor belt is connected to the chute 2 which is arranged obliquely downward. Below the chute 2, there is a cleaning tank 3 for placing cleaning liquid. The cleaning tank is provided with an ultrasonic generator, a supporting transducer and a power supply device.

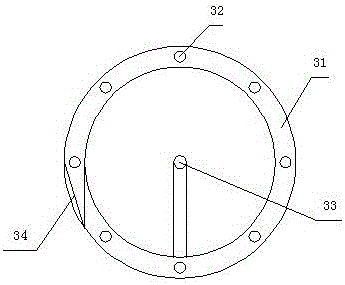

[0020] The middle part of the cleaning tank is provided with a horizontally arranged spiral transmission shaft 31. The spiral transmission shaft i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com